This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

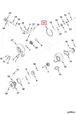

The 3535800 Retaining Ring, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty trucks. This Cummins part is integral to the efficient operation of these vehicles.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to secure components in place within a housing or on a shaft. They function by exerting a radial force that keeps parts from moving axially. This is particularly important in applications where components must remain fixed to ensure the proper functioning of the system. Retaining rings come in various designs, including internal and external types, each suited to specific applications based on the direction of the securing force required 1.

Purpose of the 3535800 Retaining Ring in Truck Operations

The 3535800 Retaining Ring plays a role in securing components within the engine systems of commercial trucks. It is specifically designed to hold parts in place under the high stress and dynamic conditions encountered in heavy-duty applications. By ensuring that components remain fixed, the retaining ring contributes to the overall stability and performance of the truck’s engine system 2.

Key Features of the 3535800 Retaining Ring

The 3535800 Retaining Ring is characterized by its robust design and material composition, which are tailored to meet the demands of heavy-duty truck applications. Made from high-strength materials, it offers durability and resistance to wear and corrosion. Its design ensures a secure fit, minimizing the risk of component displacement under operational stress 3.

Benefits of Using the 3535800 Retaining Ring

Utilizing the 3535800 Retaining Ring in truck operations provides several advantages. Its design contributes to improved reliability by securely holding components in place, which is crucial for the consistent performance of the engine system. Additionally, the ring is designed for ease of installation, reducing downtime during maintenance procedures. Its durability also means that it requires less frequent replacement, contributing to maintenance efficiency 4.

Installation Process

Installing the 3535800 Retaining Ring involves several steps to ensure it is correctly positioned and secured. The process typically requires the use of specialized tools, such as circlip pliers, to place the ring in its designated groove. Careful attention to the orientation and seating of the ring is necessary to ensure it functions as intended.

Troubleshooting Common Issues

Common issues with retaining rings may include improper seating, which can lead to component displacement, or damage to the ring itself. Diagnosing these issues involves inspecting the ring and its seating area for signs of wear or misalignment. Resolving these problems may require replacing the ring or addressing any underlying issues that contributed to its failure.

Maintenance Tips

Regular inspection of the 3535800 Retaining Ring is recommended to ensure its ongoing performance and longevity. This includes checking for signs of wear, corrosion, or displacement. Maintaining the cleanliness of the seating area and ensuring that all components are properly aligned can also contribute to the effective operation of the retaining ring.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range is designed to meet the diverse needs of its customers, ensuring efficient and reliable performance in various applications.

Cummins Retaining Ring 3535800 Compatibility

The Cummins Retaining Ring part number 3535800 is designed to fit various Cummins engine models. This retaining ring is engineered to ensure the proper alignment and secure fitment of certain engine parts, enhancing the overall performance and longevity of the engine.

Compatible Engines

- 4B3.9

- 6B5.9

- B4.5

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISBE CM800

- ISBE4 CM850

- QSB3.9 30 CM550

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

Grouping of Compatible Engines

The Cummins Retaining Ring 3535800 is compatible with a range of engines, which can be grouped based on their series and specifications:

-

ISB Series:

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISBE CM800

- ISBE4 CM850

-

QSB Series:

- QSB3.9 30 CM550

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

-

Other Models:

- 4B3.9

- 6B5.9

- B4.5

This retaining ring ensures that the engine components remain securely in place, preventing any misalignment or movement that could lead to performance issues or engine damage.

Role of Part 3535800 Retaining Ring in Engine Systems

The 3535800 Retaining Ring is a component in various engine systems, ensuring the secure assembly and operation of several key elements. In an Aftermarket Turbocharger, this retaining ring is utilized to hold the turbine wheel in place, preventing it from dislodging during high-speed rotation. This stability is vital for maintaining the turbocharger’s efficiency and longevity.

In systems involving a Heat Exchanger 30 Wastegate Turbocharger, the retaining ring plays a significant role in securing the wastegate actuator. This ensures that the wastegate operates correctly by modulating the exhaust gas flow, which is essential for regulating the turbocharger’s boost pressure.

When integrated into a standard Turbocharger, the retaining ring is often found securing the compressor wheel. This application is fundamental for maintaining the wheel’s alignment and balance, which directly impacts the turbocharger’s performance and reliability.

For a Turbocharger Kit, which typically includes various components such as the turbocharger, intercooler, and piping, the retaining ring is used in multiple places. It secures critical parts like the compressor and turbine housings, ensuring that all elements remain firmly in place under the high stresses of operation.

In a Turbocharger Repair Kit, the retaining ring is a replacement part that ensures the reassembled turbocharger functions as intended. It is used to re-secure components that may have become loose or damaged, restoring the turbocharger to its optimal working condition.

Conclusion

The 3535800 Retaining Ring is a vital component in the maintenance and operation of heavy-duty truck engines. Its robust design and material composition ensure durability and resistance to wear and corrosion, contributing to the overall stability and performance of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring efficient and reliable truck operations.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383694.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.