This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Doser Fluid Supply Module 4387305 is a component designed for use in commercial trucks. It facilitates the delivery of Diesel Exhaust Fluid (DEF) to the exhaust stream, playing a role in the operation of these vehicles. Cummins, a well-established manufacturer in the engine technology sector, produces this module as part of its commitment to innovation and sustainability in the automotive industry 1.

Basic Concepts of Doser Fluid Supply Module

The Doser Fluid Supply Module operates on the principles of the Selective Catalytic Reduction (SCR) system, designed to reduce nitrogen oxide (NOx) emissions from diesel engines. The module delivers DEF to the exhaust stream, where it reacts with NOx in the presence of a catalyst to convert these emissions into nitrogen and water vapor. This process is integral to the SCR system’s effectiveness in emissions reduction 2.

Purpose and Role in Truck Operation

The Doser Fluid Supply Module 4387305 serves a specific purpose within the operation of commercial trucks. It contributes to the reduction of emissions by ensuring the precise delivery of DEF to the exhaust stream. This action helps trucks meet stringent environmental regulations and maintain compliance with emissions standards. The module’s role is vital in the overall strategy to minimize the environmental impact of diesel engines 3.

Key Features

The Doser Fluid Supply Module 4387305 incorporates several key features that enhance its functionality and reliability. These include a robust design for durability, the use of high-quality materials to resist corrosion and wear, and technological advancements that improve the accuracy and efficiency of DEF delivery. These features collectively contribute to the module’s performance and longevity.

Benefits

Utilizing the Doser Fluid Supply Module 4387305 offers several benefits to fleet operators and the environment. These include improved emissions performance, enhanced engine efficiency due to the optimized SCR process, and potential cost savings over time as a result of reduced emissions-related penalties and improved fuel efficiency.

Installation and Integration

When installing the Doser Fluid Supply Module 4387305 into commercial truck exhaust systems, it is important to follow guidelines and best practices to ensure proper setup and functionality. This includes careful consideration of the module’s placement within the exhaust system, secure mounting to withstand vibrations, and correct electrical connections to the vehicle’s control system. Proper installation is key to the module’s effective operation and longevity.

Troubleshooting and Maintenance

Common issues that may arise with the Doser Fluid Supply Module 4387305 include clogging of the dosing nozzle, leaks in the DEF supply lines, and electrical faults. Troubleshooting these issues involves checking for obstructions, inspecting connections for signs of wear or damage, and testing electrical components for proper function. Regular maintenance, such as cleaning the dosing nozzle and inspecting the DEF supply lines, is recommended to ensure optimal performance and longevity of the module.

Regulatory Compliance

The Doser Fluid Supply Module 4387305 assists trucks in complying with various regulatory standards and emissions regulations. These regulations aim to reduce the environmental impact of diesel engines by limiting NOx emissions. Maintaining compliance is important for fleet operators to avoid penalties and contribute to cleaner air quality. The module plays a role in helping trucks meet these regulatory requirements.

Environmental Impact

The use of the Doser Fluid Supply Module 4387305 has a positive environmental impact by reducing nitrogen oxide (NOx) emissions from commercial trucks. This reduction contributes to cleaner air quality and helps mitigate the effects of air pollution. The module’s role in the SCR system is a key component in the strategy to reduce the environmental footprint of diesel engines.

Cummins Overview

Cummins is a manufacturer with a long-standing reputation in the engine technology industry. The company is known for its innovation, quality, and commitment to sustainability. Cummins’ history of developing advanced engine technologies reflects its dedication to improving the efficiency and environmental performance of diesel engines. The Doser Fluid Supply Module 4387305 is a testament to Cummins’ ongoing efforts to lead in engine technology and sustainability.

Compatibility with Cummins Engines

The Doser Fluid Supply Module 4387305 is compatible with several Cummins engine models, enhancing the efficiency and environmental performance of these engines.

F3.8 CM2350 and QSF3.8 CM2350 F107

The Doser Fluid Supply Module 4387305 is engineered to integrate seamlessly with the F3.8 CM2350 and QSF3.8 CM2350 F107 engines. These engines benefit from the precise control of urea dosing, which is essential for maintaining optimal SCR performance and reducing nitrogen oxide (NOx) emissions.

QSB6.7 CM2350 B105

The QSB6.7 CM2350 B105 engine also supports the use of the Doser Fluid Supply Module 4387305. This engine, known for its robust performance and reliability, integrates the module to manage the urea dosing process effectively.

QSL9 CM2350 L102

Similarly, the QSL9 CM2350 L102 engine is designed to work with the Doser Fluid Supply Module 4387305. This engine’s compatibility with the module ensures that the urea dosing process is managed with high accuracy.

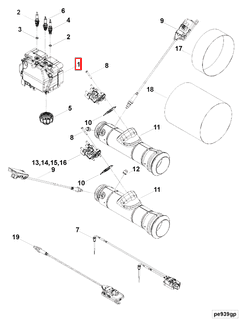

Role of Part 4387305 Doser Fluid Supply Module in Engine Systems

The Part 4387305 Doser Fluid Supply Module is an integral component in the aftertreatment system of modern engines, particularly those equipped with Selective Catalytic Reduction (SCR) technology. This module is responsible for the precise delivery of Diesel Exhaust Fluid (DEF), also known as AdBlue, into the exhaust stream.

When integrated with the aftertreatment device, the Doser Fluid Supply Module works in conjunction with the Exhaust Gas Recirculation (EGR) system and the Diesel Particulate Filter (DPF) to ensure optimal emissions reduction. The module is connected to the DEF tank via a series of hoses and is controlled by the Engine Control Unit (ECU), which monitors various parameters such as exhaust temperature, engine load, and emissions levels.

The Doser Fluid Supply Module injects DEF into the exhaust stream upstream of the SCR catalyst. The DEF then decomposes into ammonia and carbon dioxide, which react with nitrogen oxides (NOx) in the exhaust to form harmless nitrogen and water vapor. This process is essential for meeting stringent emissions regulations.

Conclusion

In summary, the Doser Fluid Supply Module 4387305 plays a significant role in the aftertreatment system by ensuring the accurate and timely delivery of DEF, thereby enhancing the efficiency of the SCR catalyst and contributing to reduced emissions. Its compatibility with various Cummins engines underscores its importance in modern diesel engine technology.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.