4387302

Male Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding The Cummins 4387302 Male Connector

Introduction to Cummins 4387302 Male Connector

The Cummins 4387302 Male Connector is a critical component in the engine systems of commercial trucks. This part plays a pivotal role in ensuring the seamless operation of the engine by facilitating the connection between various engine components. Its importance cannot be overstated, as it directly impacts the efficiency and reliability of the engine, making it a vital part of the overall engine system 1.

Basic Concepts of a Male Connector

A male connector, by definition, is a type of fitting used to join two components together, typically in fluid systems such as fuel, oil, or coolant lines. In the context of engine systems, male connectors ensure a secure and leak-proof connection, allowing for the efficient transfer of fluids under pressure. Common applications of male connectors in commercial trucks include fuel lines, oil circuits, and coolant systems, where they are essential for maintaining system integrity and performance 2.

Purpose and Role of the Cummins 4387302 Male Connector

The Cummins 4387302 Male Connector is specifically designed to enhance the operation and efficiency of Cummins engines. It contributes to the overall performance of the engine by ensuring a reliable connection between components, which is crucial for maintaining optimal engine performance. This part is integral to the engine’s ability to operate efficiently, highlighting its importance in the engine’s design and function 3.

Troubleshooting and Maintenance of the Cummins 4387302 Male Connector

Common issues associated with the 4387302 Male Connector include leaks, corrosion, and wear, which can compromise the engine’s performance. To troubleshoot these problems, it is essential to conduct regular inspections and follow a step-by-step guide to identify and resolve issues promptly. Maintenance tips for ensuring the longevity and optimal performance of the 4387302 Male Connector include regular cleaning, checking for signs of wear or damage, and replacing the connector if necessary. Regular inspections and preventive maintenance are crucial for preventing issues and ensuring the connector continues to function effectively.

Cummins: A Leader in Engine Solutions

Cummins has a long-standing reputation as a leader in engine solutions, with a history of innovation and commitment to quality. The company’s dedication to producing reliable and durable engine components is evident in their products, including the 4387302 Male Connector. Cummins ensures the reliability and durability of their products through rigorous testing and quality control processes, making them a trusted choice for commercial truck engines.

Expert Insights and Best Practices

Industry experts emphasize the importance of proper maintenance and troubleshooting for male connectors to ensure engine efficiency and longevity. Best practices for engineers, mechanics, and fleet operators include following manufacturer guidelines for maintenance, conducting regular inspections, and addressing issues promptly. Real-world examples and case studies demonstrate the effectiveness of proper maintenance and troubleshooting, highlighting the importance of these practices in maintaining engine performance.

Cummins Male Connector 4387302 Compatibility

The Cummins Male Connector part number 4387302 is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. This connector is integral for maintaining fluid flow and system integrity within the engine’s hydraulic or fuel systems.

D-Series Engines

- D4.0 CM2620 D103B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

The D-Series engines, including the D4.0 CM2620 D103B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, and F4.5 CM2620 F139B, are equipped with the 4387302 Male Connector. This part is essential for these engines’ hydraulic systems, ensuring that fluid connections are secure and reliable.

QSB and QSF Engines

- QSB6.7 CM2350 B105

- QSF3.8 CM2350 F107

The QSB6.7 CM2350 B105 and QSF3.8 CM2350 F107 engines also utilize the 4387302 Male Connector. This connector is critical in maintaining the integrity of the fuel and hydraulic systems within these engines, ensuring optimal performance and longevity.

QSL Engine

- QSL9 CM2350 L102

The QSL9 CM2350 L102 engine is another model that incorporates the 4387302 Male Connector. This part is vital for the engine’s hydraulic system, ensuring that all fluid connections are robust and reliable.

By using the 4387302 Male Connector, these engines benefit from a standardized part that ensures compatibility and ease of maintenance, making it a crucial component for the reliable operation of these Cummins engines.

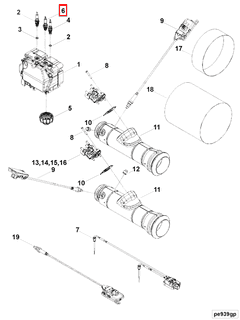

Role of Part 4387302 Male Connector in Engine Systems

Part 4387302 Male Connector is integral to the seamless operation of various engine systems, particularly in the context of aftertreatment and fluid management. This component ensures reliable connections between different modules and devices, facilitating the efficient transfer of fluids and data.

Integration with Aftertreatment Systems

In aftertreatment systems, the Male Connector is employed to link the Aftertreatment Device with the Doser Fluid Supply Module. This connection is essential for the precise delivery of fluid to the Doser Pump, which in turn ensures the proper functioning of the Fluid Doser. The Male Connector’s role here is to maintain a secure and leak-proof interface, allowing for consistent fluid flow and reducing the risk of system malfunctions.

Enhancing Device Performance

The Male Connector also plays a significant role in enhancing the performance of individual devices within the engine system. By providing a stable connection between the Aftertreatment Device and other components, it ensures that the device operates within optimal parameters. This stability is vital for the accurate monitoring and regulation of emissions, contributing to overall engine efficiency and compliance with environmental standards.

Facilitating Data Transfer

Beyond fluid transfer, the Male Connector is instrumental in facilitating data transfer between various engine components. This data exchange is crucial for the engine’s control unit to make real-time adjustments, ensuring that the aftertreatment system responds effectively to changing conditions. The reliable connection provided by the Male Connector is therefore essential for the overall intelligence and adaptability of the engine system.

Supporting Doser Fluid Supply Module

The Doser Fluid Supply Module relies on the Male Connector to maintain a consistent supply of fluid to the Doser Pump. This connection ensures that the module can deliver the necessary fluid volumes at the required pressure, supporting the efficient operation of the Fluid Doser. The Male Connector’s design is tailored to withstand the pressures and temperatures associated with fluid transfer, ensuring durability and reliability in demanding engine environments.

Conclusion

In summary, the Cummins 4387302 Male Connector is a key component in the intricate network of engine systems, particularly within aftertreatment and fluid management contexts. Its role in providing secure, leak-proof connections between critical components underscores its importance in maintaining engine performance, efficiency, and compliance with environmental regulations. Proper maintenance and troubleshooting are essential for ensuring the longevity and optimal performance of this part, underscoring the importance of regular inspections and preventive maintenance. By understanding the role and importance of the 4387302 Male Connector, engineers and mechanics can ensure the continued efficiency and reliability of commercial truck engines.

-

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Awari, G. K., Kumbhar, V. S., & Tirpude, R. B. (n.d.). Automotive Systems Principles and Practice. Taylor Francis.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.