3062009

Injector Plunger Link

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Injector Plunger Link 3062009 by Cummins is a component designed to facilitate the operation of the fuel injection system in heavy-duty trucks. Its purpose is to ensure precise and efficient fuel delivery to the engine, which is vital for optimal performance and fuel efficiency. This part interacts closely with other elements of the fuel injection system, including the injector pump and nozzles, to maintain consistent fuel atomization and delivery 1.

Function and Operation

The Injector Plunger Link 3062009 operates by connecting the injector pump to the nozzles within the fuel injection system. When the injector pump pressurizes the fuel, the plunger link transmits this pressure to the nozzles, allowing for the precise injection of fuel into the combustion chamber. This interaction ensures that the fuel is atomized correctly, which is crucial for efficient combustion and engine performance 2. The plunger link’s design allows it to withstand high pressures and temperatures, ensuring reliable operation under various driving conditions.

Key Features

This Cummins part is constructed from high-quality materials that offer durability and resistance to wear and corrosion. Its design includes precise machining to ensure a tight fit and smooth operation within the fuel injection system. Unique characteristics such as its robust construction and precise engineering enhance its performance, contributing to consistent fuel delivery and efficient engine operation 3.

Role in Truck Operation

In the operation of a heavy-duty truck, the Injector Plunger Link 3062009 plays a significant role by ensuring that fuel is delivered to the engine in a controlled and efficient manner. This contributes to improved fuel efficiency, as the engine can burn fuel more effectively. Additionally, consistent fuel delivery enhances engine performance, allowing the truck to operate smoothly under various loads and conditions. The reliability of the plunger link also contributes to the overall durability and longevity of the engine.

Benefits

Using the Injector Plunger Link 3062009 offers several benefits. Improved fuel atomization ensures that the fuel mixes efficiently with air in the combustion chamber, leading to more complete combustion and better engine performance. Consistent fuel delivery helps maintain stable engine operation, reducing the likelihood of misfires and other performance issues. Enhanced engine performance resulting from the use of this component can lead to increased productivity and reduced maintenance costs over time.

Maintenance and Troubleshooting

To ensure optimal performance of the Injector Plunger Link 3062009, regular maintenance is necessary. This includes periodic inspections for signs of wear or damage, as well as cleaning to remove any buildup that could affect its operation. Common issues that may arise include leaks or inconsistent fuel delivery, which can often be traced back to wear on the plunger link or related components. Troubleshooting steps may involve inspecting the link for damage, ensuring proper fit within the fuel injection system, and replacing any worn or damaged parts as needed. Regular inspections and timely replacements are important for maintaining the efficiency and reliability of the fuel injection system.

Installation Considerations

When installing the Injector Plunger Link 3062009, it is important to follow best practices to ensure proper fit and function within the fuel injection system. This includes verifying that all components are clean and free from debris before installation, as well as ensuring that the link is properly aligned with the injector pump and nozzles. Careful attention to these details will help ensure that the plunger link operates efficiently and contributes to the overall performance of the engine.

Compatibility and Applications

The Injector Plunger Link 3062009 is designed for use in specific types of engines and truck models. It is important to consult the manufacturer’s guidelines to ensure compatibility with the intended application. Specific application notes or considerations may include adjustments for different fuel types or operating conditions, ensuring that the plunger link performs optimally in its intended environment.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the heavy-duty truck industry. With a history of producing reliable and efficient engine components, Cummins has established a reputation for excellence. The company’s product range includes a variety of engine components designed to enhance performance, fuel efficiency, and durability. Cummins’ dedication to quality is evident in the design and manufacturing of components like the Injector Plunger Link 3062009, which are engineered to meet the demanding requirements of heavy-duty applications.

Cummins Injector Plunger Link 3062009 Compatibility

The Cummins Injector Plunger Link part number 3062009 is designed to fit various Cummins engines, ensuring precise fuel delivery and optimal engine performance. This part is integral to the injector system, facilitating the movement of the injector plunger within the injector body.

M11 Series Engines

The injector plunger link 3062009 is compatible with both the M11 CELECT PLUS and M11 MECHANICAL engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The link ensures that the injector operates smoothly, maintaining the engine’s performance and fuel efficiency.

N14 Series Engine

The N14 MECHANICAL engine also utilizes the injector plunger link 3062009. This engine is recognized for its durability and power, often used in large trucks and industrial applications. The link’s role in this engine is crucial for the precise timing and delivery of fuel, which is essential for the engine’s overall efficiency and longevity.

NH/NT Series Engines

The NH/NT 855 engine is another model that benefits from the injector plunger link 3062009. This engine is designed for versatility and reliability, commonly used in agricultural and construction equipment. The link ensures that the injector functions correctly, contributing to the engine’s smooth operation and consistent power output.

V903 and VTA903 CM2250 V105 Engines

The V903 and VTA903 CM2250 V105 engines also incorporate the injector plunger link 3062009. These engines are engineered for high performance and efficiency, often found in heavy-duty trucks and industrial machinery. The link’s precision in facilitating the injector’s movement is vital for maintaining the engine’s performance and fuel economy.

By ensuring compatibility across these engines, the injector plunger link 3062009 plays a critical role in the overall functionality and reliability of Cummins engines.

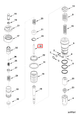

Role of Part 3062009 Injector Plunger Link in Engine Systems

The Injector Plunger Link, part number 3062009, is an integral component in the orchestration of various engine systems, ensuring efficient and precise fuel delivery. This part interfaces directly with the injector, facilitating the movement necessary for fuel injection into the cylinder.

When the camshaft rotates, it actuates the cam follower housing, which in turn engages the Injector Plunger Link. This mechanical interaction ensures that the injector is precisely timed with the engine’s combustion cycle. The link’s movement is transferred to the injector via the injector plumbing, allowing for controlled fuel delivery.

In high-performance applications, the Injector Plunger Link works in conjunction with EBM: Performance Parts to enhance fuel atomization and combustion efficiency. The link’s role becomes even more significant when paired with an EBM: Injector, as it ensures that the increased fuel flow is managed effectively.

The fuel connection and oil manifold also play supporting roles, providing the necessary pathways for fuel and lubrication. The Injector Plunger Link’s operation is further influenced by the oil control valve and its mounting plumbing, which regulate oil pressure to the injector.

In turbocharged engines, the link must withstand additional stress from the turbocharger, making its robust design and precise engineering essential for reliable performance. The connecting rod and piston assembly, driven by the camshaft, relies on the Injector Plunger Link to maintain fuel injection timing, directly impacting engine efficiency and power output.

Overall, the Injector Plunger Link is a linchpin in the complex interplay of engine components, ensuring that fuel is delivered at the right time and in the right quantity for optimal engine performance.

Conclusion

The Injector Plunger Link 3062009 by Cummins is a critical component in the fuel injection system of heavy-duty trucks. Its role in ensuring precise and efficient fuel delivery contributes to optimal engine performance and fuel efficiency. Regular maintenance and proper installation are essential for the reliable operation of this part. By understanding its function, benefits, and compatibility, truck operators and maintenance professionals can ensure the longevity and efficiency of their vehicles.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.