This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

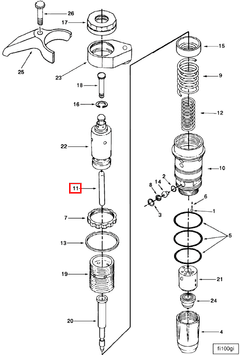

The Injector Plunger Link 3028447 is a component manufactured by Cummins, a prominent entity in the automotive industry, especially recognized for its heavy-duty truck engines. This part is integral to the fuel injection system, ensuring that fuel is delivered with precision to the engine’s combustion chambers. Cummins, with its long-standing reputation for quality and innovation, produces this component to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Injector Plunger Link

The Injector Plunger Link operates on the fundamental principle of transferring motion within the fuel injection system. It connects the injector plunger to other components, facilitating the precise delivery of fuel into the engine. This link ensures that the fuel is injected at the correct moment and in the right quantity, which is vital for the engine’s efficient operation. The design and functionality of the Injector Plunger Link are essential for maintaining the synchronization between fuel delivery and engine operation 2.

Role of the Injector Plunger Link in Truck Operation

In the operation of a truck’s engine, the Injector Plunger Link plays a significant role by ensuring that the fuel injection process is both timely and accurate. This precision contributes to several aspects of engine performance, including fuel efficiency, power output, and emissions control. By maintaining the integrity of the fuel injection timing, the Injector Plunger Link helps in optimizing the combustion process, which in turn enhances overall engine performance and reduces harmful emissions 3.

Key Features of the Injector Plunger Link 3028447

The Injector Plunger Link 3028447 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring longevity in harsh operating conditions. The design of the link includes precise machining and tolerances to ensure smooth operation and reliable performance. Additionally, any unique characteristics, such as specific coatings or treatments, further contribute to its durability and efficiency 4.

Benefits of Using the Injector Plunger Link 3028447

Utilizing the Injector Plunger Link 3028447 offers several advantages. It contributes to improved fuel economy by ensuring that fuel is delivered efficiently to the engine. This precise fuel delivery also enhances engine performance, providing consistent power output. Furthermore, the durable construction of the link reduces maintenance requirements and extends the component’s lifespan, offering long-term value to the user.

Troubleshooting Common Issues

Identifying and addressing common issues with the Injector Plunger Link 3028447 is important for maintaining engine performance. Symptoms of a faulty or worn link may include irregular engine operation, decreased fuel efficiency, or increased emissions. Diagnosing these issues typically involves inspecting the link for signs of wear, corrosion, or damage. Repair or replacement of the link, following manufacturer guidelines, can resolve these issues and restore optimal engine performance.

Maintenance Tips

To ensure the Injector Plunger Link 3028447 operates at its best, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, cleaning the link to remove any contaminants, and adhering to recommended replacement intervals. Proper maintenance not only enhances the performance of the Injector Plunger Link but also contributes to the overall reliability and efficiency of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range serves various industries, including heavy-duty trucking, where reliability and performance are paramount. Cummins’ dedication to excellence is evident in every component it produces, including the Injector Plunger Link 3028447.

Cummins Injector Plunger Link 3028447 Compatibility

The Cummins Injector Plunger Link part number 3028447 is a critical component in the fuel injection system of various diesel engines. This part is designed to ensure precise control over the fuel injection process, which is essential for optimal engine performance and efficiency.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Injector Plunger Link 3028447 plays a pivotal role in the operation of the fuel injectors. It connects the injector plunger to the injector body, facilitating the movement necessary for the injection of fuel into the combustion chamber. This link ensures that the injector operates smoothly and accurately, contributing to the engine’s overall reliability and performance.

NH/NT 855

Similarly, in the NH/NT 855 engines, the Injector Plunger Link 3028447 is integral to the fuel injection mechanism. This part ensures that the injector plunger moves with precision, allowing for the correct timing and quantity of fuel to be injected. The reliability of this component is crucial for maintaining the engine’s efficiency and power output.

V903 and VTA903 CM2250 V105

The V903 and VTA903 CM2250 V105 engines also benefit from the use of the Injector Plunger Link 3028447. In these engines, the link is essential for the proper functioning of the fuel injectors, ensuring that the fuel is delivered to the combustion chamber in a controlled and efficient manner. This part’s design and durability are key to the engines’ performance and longevity.

Each of these engines relies on the Injector Plunger Link 3028447 to maintain the integrity of the fuel injection system. The precision and reliability of this component are critical for the engines’ overall performance and efficiency.

Role of Part 3028447 Injector Plunger Link in Engine Systems

The Injector Plunger Link, identified by part number 3028447, is an integral component within the fuel injection system of an engine. Its primary function is to facilitate the precise movement of the injector plunger, which is essential for the accurate delivery of fuel into the combustion chamber.

Interaction with the Connecting Rod and Piston

The Injector Plunger Link works in conjunction with the connecting rod and piston assembly. As the piston moves downward during the intake stroke, it creates a vacuum that draws air into the cylinder. During the compression stroke, the piston moves upward, compressing the air-fuel mixture. The precise timing and force exerted by the Injector Plunger Link ensure that the fuel is injected at the optimal moment, enhancing combustion efficiency and power output.

Coordination with the Cylinder Head

The cylinder head houses the intake and exhaust valves, as well as the fuel injectors. The Injector Plunger Link plays a significant role in coordinating the injection process with the opening and closing of these valves. This synchronization is vital for maintaining engine performance and efficiency. The link ensures that the fuel is injected just before the air-fuel mixture is compressed, allowing for a more complete and efficient burn during the power stroke.

Integration with EBM Performance Parts

EBM Performance Parts, including high-performance injectors and top stop (step) injectors, rely on the Injector Plunger Link for optimal function. These performance parts are designed to deliver fuel more precisely and at higher pressures, which can significantly enhance engine performance. The Injector Plunger Link ensures that these high-performance injectors operate within their designed parameters, maximizing the benefits of the upgraded components.

Enhancing Injector Performance

The Injector Plunger Link is particularly important for top stop injectors, which feature a stepped design to improve fuel atomization and combustion. By precisely controlling the movement of the injector plunger, the link ensures that the fuel is delivered in the correct quantity and at the right time, which is essential for the effective operation of these advanced injectors.

Contribution to Overall Engine Performance

In summary, the Injector Plunger Link (part 3028447) is a key component that enhances the performance of various engine systems. Its role in coordinating the movement of the injector plunger with the piston, cylinder head, and high-performance injectors ensures that fuel is delivered efficiently and effectively, contributing to improved engine performance, power output, and fuel efficiency.

Conclusion

The Injector Plunger Link 3028447 by Cummins is a critical component in the fuel injection system of heavy-duty engines. Its precise function in delivering fuel to the combustion chamber ensures optimal engine performance, efficiency, and reliability. Regular maintenance and proper troubleshooting of this part are essential for maintaining the overall health and performance of the engine.

-

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.