This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

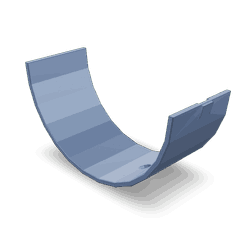

The Cummins 3643986 Connecting Rod Bearing is a critical component in the engine assembly of heavy-duty trucks. It facilitates smooth operation between the connecting rod and the crankshaft journal, ensuring efficient power transmission and minimizing friction. This bearing is essential for maintaining the overall performance and longevity of the engine 1.

Function and Operation

Connecting rod bearings provide a low-friction interface between the connecting rod and the crankshaft journal. These bearings are designed to support the loads generated during engine operation while allowing for rotational movement. By reducing friction, they help maintain the efficiency and reliability of the engine. The Cummins 3643986 is specifically engineered to handle the high stresses and loads encountered in heavy-duty truck engines 2.

Purpose of the Cummins 3643986 Connecting Rod Bearing

This Cummins part is integral to the operation of a truck engine. It ensures that the connecting rod can move smoothly over the crankshaft journal, which is vital for the conversion of linear motion into rotational motion. This bearing contributes to the smooth and efficient performance of the engine by minimizing friction and wear, thereby enhancing the engine’s durability and reliability 3.

Key Features

The Cummins 3643986 Connecting Rod Bearing boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer excellent resistance to wear and corrosion. The design of the bearing includes precision-machined surfaces to ensure a perfect fit and optimal performance. Additionally, it features advanced lubrication grooves that promote efficient oil distribution, further reducing friction and heat generation 4.

Benefits

Using the Cummins 3643986 Connecting Rod Bearing offers several benefits. It contributes to improved engine efficiency by reducing friction between the connecting rod and the crankshaft journal. This reduction in friction leads to lower wear and tear on engine components, enhancing the overall reliability of the engine. Moreover, the durable construction of the bearing ensures long-lasting performance, making it a valuable component for heavy-duty applications.

Installation and Maintenance

Proper installation and maintenance of this part are crucial for ensuring optimal performance and longevity. During installation, it is important to follow manufacturer guidelines to ensure the bearing is correctly positioned and securely fitted. Regular maintenance checks should be performed to monitor the condition of the bearing and address any signs of wear or damage promptly. This includes inspecting the bearing surfaces for signs of wear, ensuring proper lubrication, and replacing the bearing if necessary to prevent engine failure.

Troubleshooting Common Issues

Common issues with connecting rod bearings may include excessive wear, noise, or failure. These problems can often be traced back to inadequate lubrication, misalignment, or the use of incompatible components. Troubleshooting steps may involve inspecting the lubrication system to ensure proper oil flow, checking the alignment of the connecting rod and crankshaft, and verifying that all components are compatible and correctly installed. Addressing these issues promptly can help prevent more severe engine problems.

Importance of Regular Inspections

Regular inspections of connecting rod bearings are vital for identifying potential issues early and preventing catastrophic engine failure. During inspections, it is important to look for signs of wear, such as scoring or pitting on the bearing surfaces, as well as any unusual noises that may indicate bearing failure. Early detection of these issues allows for timely maintenance or replacement, ensuring the continued reliable operation of the engine.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has built a legacy of producing high-quality engine components and systems. The company is committed to innovation, quality, and customer satisfaction, making it a trusted name in the industry. Cummins’ dedication to excellence is evident in their comprehensive range of products, including the Cummins 3643986 Connecting Rod Bearing, which is designed to meet the demanding requirements of heavy-duty applications.

Conclusion

The Cummins 3643986 Connecting Rod Bearing is a vital component for the efficient and reliable operation of heavy-duty truck engines. Its design and features contribute to reduced friction, enhanced durability, and overall engine performance. Proper installation, regular maintenance, and timely inspections are essential for maximizing the lifespan and performance of this critical part.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.