This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

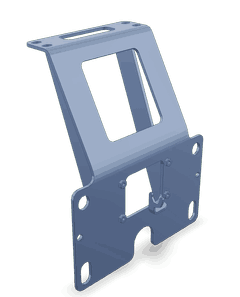

The Water Tube Bracket 5266187, manufactured by Cummins, is a critical component in the engine systems of the QSK60, CM850, and MCRS engines. This part plays a pivotal role in the engine’s cooling system by providing a secure mounting point for water tubes. These tubes are essential for transferring heat away from the engine, ensuring optimal operating temperatures and preventing overheating 1.

Basic Concepts of Water Tube Brackets

A Water Tube Bracket is a structural component used in engine systems to support and secure water tubes, which are part of the cooling system. Its function is to ensure that the water tubes remain in the correct position and orientation, facilitating efficient coolant flow. This, in turn, contributes to the overall efficiency and performance of the engine by helping to maintain optimal operating temperatures 2.

Purpose of the 5266187 Water Tube Bracket

In the QSK60 engine, the Water Tube Bracket 5266187 is strategically positioned to maintain the integrity of the cooling system. Its design allows for efficient heat dissipation, which is crucial for the high-performance demands of this engine. The bracket’s robust construction ensures that it can withstand the stresses of continuous operation, contributing to the engine’s reliability and longevity 3.

Similarly, in the CM850 engine, the Water Tube Bracket 5266187 is integral to the cooling system’s functionality. This engine, known for its durability and efficiency, relies on precise engineering components like the water tube bracket to maintain its operational standards. The bracket’s placement and design are tailored to the specific needs of the CM850, ensuring that the cooling system operates seamlessly 4.

The MCRS engine also benefits from the Water Tube Bracket 5266187. This part is essential for the MCRS engine’s cooling system, providing a stable and reliable mounting point for the water tubes. The bracket’s design is optimized for the MCRS engine’s unique requirements, ensuring that the cooling system functions effectively under various operating conditions 5.

Key Features

The 5266187 Water Tube Bracket is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design incorporates precise engineering to allow for a secure fit and easy installation. Additionally, the bracket may feature unique characteristics such as reinforced mounting points or specialized coatings to further improve its functionality and longevity 6.

Benefits

The use of the 5266187 Water Tube Bracket offers several benefits. It contributes to improved engine efficiency by ensuring that the cooling system operates as intended. The enhanced durability of the bracket means fewer replacements are needed, potentially leading to cost savings for fleet operators. Furthermore, its reliable performance helps in maintaining the engine’s optimal operating conditions, which can extend the engine’s lifespan 7.

Installation Process

Installing the 5266187 Water Tube Bracket requires careful attention to detail to ensure proper fitting and function. The process involves securing the bracket to the engine block using the appropriate fasteners. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening, which could lead to leaks or bracket failure. Tools required may include a torque wrench and socket set. Ensuring the water tubes are correctly aligned before securing the bracket is also a critical step in the installation process 8.

Troubleshooting Common Issues

Common problems associated with Water Tube Brackets include leaks and misalignment. Leaks may occur if the bracket is not properly secured or if there is damage to the water tubes. Misalignment can disrupt the flow of coolant, leading to inefficient cooling. Troubleshooting steps may involve inspecting the bracket and water tubes for signs of wear or damage, ensuring all fasteners are tightened to the correct specifications, and verifying the alignment of the water tubes 9.

Maintenance Tips

Regular maintenance of the 5266187 Water Tube Bracket is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket and surrounding areas can prevent the buildup of debris that may interfere with its function. Following the manufacturer’s recommended inspection intervals and maintenance procedures will help in identifying potential issues before they lead to more significant problems 10.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the engine industry, known for its commitment to producing high-quality engine components. With a rich history and a strong reputation for reliability and performance, Cummins continues to be a preferred choice for commercial vehicle operators. Their dedication to innovation and quality ensures that components like the 5266187 Water Tube Bracket meet the demanding requirements of modern engines 11.

Conclusion

The Water Tube Bracket 5266187 by Cummins is a vital component in the cooling systems of various engines, including the QSK60, CM850, and MCRS. Its role in maintaining optimal engine temperature and efficiency is crucial for the performance and longevity of these engines. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this component.

-

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩ -

Cummins Inc. (n.d.). Service Manual (2883621) for QSB6.7 CM2250 EC (173 HP or Below).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.