4924555

Water Transfer Tube

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4924555 Water Transfer Tube is a component designed to facilitate the efficient operation of commercial trucks by ensuring proper coolant circulation. This part is integral to the cooling system, contributing to the maintenance of optimal engine temperature and overall system efficiency 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to flow between different components, such as the engine block, radiator, and other heat exchangers. Its function is to maintain a consistent flow of coolant, which absorbs heat from the engine and dissipates it through the radiator, thereby regulating engine temperature 2.

Purpose of the 4924555 Water Transfer Tube

The 4924555 Water Transfer Tube plays a role in the truck’s cooling system by circulating coolant through the engine and radiator. This circulation helps in maintaining the engine at an optimal operating temperature, preventing overheating and ensuring efficient engine performance 3.

Key Features

The 4924555 Water Transfer Tube is characterized by its robust design and the materials used in its construction, which are chosen for their durability and resistance to corrosion. These features contribute to the tube’s ability to withstand the high pressures and temperatures within the cooling system, ensuring reliable performance over time.

Benefits

The advantages of the 4924555 Water Transfer Tube include enhanced engine efficiency due to consistent coolant circulation, reduced risk of engine overheating, and prolonged lifespan of engine components by maintaining optimal operating temperatures.

Installation Process

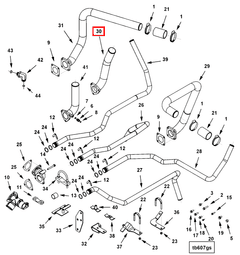

Installing the 4924555 Water Transfer Tube involves several steps to ensure proper fit and function. Preparation includes ensuring the engine is cool and the cooling system is drained. The tube should be aligned with the corresponding fittings, secured with appropriate fasteners, and the system should be refilled with coolant before starting the engine to check for leaks.

Common Issues and Troubleshooting

Typical problems with Water Transfer Tubes may include leaks or blockages. Troubleshooting these issues involves inspecting the tube and connections for signs of wear or damage, cleaning or replacing components as necessary, and ensuring all connections are tight and secure.

Maintenance Tips

To ensure the longevity and efficient operation of the 4924555 Water Transfer Tube, regular maintenance is recommended. This includes periodic inspections for signs of wear or corrosion, cleaning the tube and connections to remove any buildup, and ensuring the cooling system is free of contaminants.

Compatibility and Application

The 4924555 Water Transfer Tube is designed for use in specific models and series of trucks and engines, ensuring compatibility and optimal performance within the intended applications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

Water Transfer Tube (Part 4924555) Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 4924555, is a critical component in the cooling systems of various Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient thermal management and preventing overheating.

QSK60 and CM850 Engines

The QSK60 and CM850 engines, both part of Cummins’ heavy-duty diesel engine lineup, are engineered for demanding applications such as marine and power generation. The Water Transfer Tube in these engines is integral to maintaining optimal operating temperatures. It connects the engine’s water pump to the radiator, ensuring a consistent flow of coolant that dissipates heat effectively. This part’s precision engineering is crucial for the longevity and performance of these robust engines.

MCRS Engines

The MCRS engines, another segment of Cummins’ portfolio, are designed for medium-duty applications, including construction and agricultural machinery. The Water Transfer Tube in these engines serves a similar purpose as in the QSK60 and CM850 models. It ensures that the coolant circulates efficiently, maintaining the engine’s temperature within safe limits. This is particularly important in environments where the engine is subjected to heavy loads and varying operational conditions.

Grouping for Efficiency

The Water Transfer Tube’s design and functionality are optimized for the specific cooling requirements of each engine group. For the QSK60 and CM850 engines, the tube must handle higher thermal loads and pressures due to their use in marine and power generation applications. In contrast, the MCRS engines, while still requiring efficient thermal management, operate under different conditions that demand a slightly different approach in coolant flow management.

The Water Transfer Tube’s role in these engines underscores the importance of precise engineering and material selection in ensuring the engines’ reliability and efficiency.

Role of Part 4924555 Water Transfer Tube in Engine Systems

The part 4924555 Water Transfer Tube is an essential component in the auxiliary cooling system of various engine setups. It facilitates the efficient movement of coolant between the engine and the auxiliary cooling components, ensuring that the engine operates within optimal temperature ranges.

In the auxiliary cooling system, the Water Transfer Tube connects to the engine’s coolant passages and the auxiliary cooler. This connection allows for the continuous circulation of coolant, which absorbs excess heat from the engine. The coolant then travels through the Water Transfer Tube to the auxiliary cooler, where it releases the absorbed heat and is subsequently returned to the engine. This cycle is vital for maintaining engine temperature, especially under high-load conditions or in environments where the primary cooling system may be insufficient.

The Water Transfer Tube also interfaces with temperature sensors and thermostats within the system. These components monitor the coolant temperature and regulate the flow to prevent overheating. The precise fit and sealing properties of the Water Transfer Tube ensure that there are no leaks, maintaining the integrity of the cooling system.

Additionally, the Water Transfer Tube works in conjunction with the water pump, which drives the circulation of coolant throughout the system. The consistent flow provided by the Water Transfer Tube helps in evenly distributing the coolant, enhancing the overall efficiency of the cooling process.

Conclusion

In summary, the part 4924555 Water Transfer Tube plays a significant role in the auxiliary cooling system by ensuring the smooth and efficient transfer of coolant, thereby contributing to the stable operation of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.