4381249

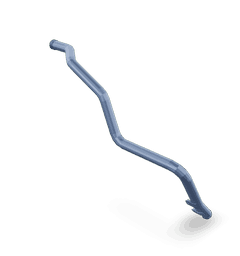

Water Transfer Tube

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4381249 Water Transfer Tube is a component designed to facilitate the efficient operation of commercial trucks. Its purpose is to ensure the proper circulation of coolant within the engine cooling system, thereby maintaining optimal engine temperature. This part is significant in the context of truck operations, as it contributes to the overall reliability and performance of the vehicle.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a component within the cooling system that facilitates the movement of coolant from one part of the engine to another. Its function is to ensure that the coolant is evenly distributed, which helps in maintaining a consistent engine temperature. The tube operates by allowing coolant to flow through it, which is driven by the water pump in the engine. This circulation is vital for dissipating heat generated by the engine, preventing overheating and ensuring efficient engine operation 1.

Purpose of the 4381249 Water Transfer Tube

The 4381249 Water Transfer Tube plays a role in the engine cooling system by directing coolant flow to critical areas of the engine that require cooling. This ensures that the engine maintains an optimal operating temperature, which is crucial for performance and longevity. By facilitating efficient coolant circulation, the tube contributes to the overall stability and reliability of the truck’s engine, enhancing its performance in various operating conditions 2.

Key Features

The design and construction of the 4381249 Water Transfer Tube incorporate several features that enhance its performance. It is made from durable materials that can withstand the high temperatures and pressures within the engine cooling system. The build quality ensures a secure fit and reliable operation. Unique characteristics of the tube may include specific dimensions and fittings that are tailored to the requirements of the engine it serves, ensuring compatibility and efficient coolant flow 3.

Benefits

The advantages provided by the 4381249 Water Transfer Tube include improved cooling efficiency, which is beneficial for maintaining engine temperature within optimal ranges. Its durability ensures long-term reliability, even in heavy-duty applications where the engine is subjected to rigorous conditions. The tube’s design contributes to the overall efficiency of the cooling system, which can lead to better engine performance and longevity 4.

Installation Process

Installing the 4381249 Water Transfer Tube requires following a step-by-step process to ensure proper fit and function. The installation may involve using specific tools or equipment to secure the tube in place and ensure there are no leaks in the cooling system. Best practices for installation include careful alignment with the engine’s coolant pathways and verifying that all connections are tight and secure.

Common Issues and Troubleshooting

Typical problems that may arise with the 4381249 Water Transfer Tube include leaks or blockages within the tube. These issues can affect the efficiency of the cooling system and should be addressed promptly. Troubleshooting methods may involve inspecting the tube for signs of wear or damage, checking for proper alignment and fit within the engine, and ensuring that all connections are secure. Addressing these issues can help maintain the integrity of the cooling system and prevent engine overheating.

Maintenance Tips

Routine maintenance practices can prolong the lifespan of the 4381249 Water Transfer Tube. This includes regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any buildup within the tube, and following replacement guidelines when necessary. Proper maintenance ensures that the tube continues to function efficiently within the cooling system, contributing to the overall performance and reliability of the truck.

About Cummins

Cummins Inc. is a company with a history of providing quality products for the commercial truck industry. Its product offerings include a range of engine and component solutions designed to meet the demands of various fleet operations. Cummins is known for its reputation in the industry, which is built on a foundation of quality, reliability, and innovation. The 4381249 Water Transfer Tube is an example of Cummins’ commitment to providing components that enhance the performance and reliability of commercial trucks.

Water Transfer Tube (Part 4381249) in Cummins Engines

The Water Transfer Tube (part number 4381249) is a critical component in the cooling systems of various Cummins engines, including the QSK45 and CM500 series. This part is integral to the efficient operation of the engine’s cooling system, ensuring that the engine maintains optimal operating temperatures.

QSK45 Series

In the QSK45 series, the Water Transfer Tube is designed to facilitate the transfer of coolant between different parts of the engine’s cooling system. This is particularly important in maintaining the temperature balance across the engine, which is crucial for performance and longevity. The QSK45 engines, known for their robust design and high power output, benefit from the precise and reliable operation of the Water Transfer Tube.

CM500 Series

Similarly, in the CM500 series, the Water Transfer Tube plays a pivotal role in the engine’s cooling mechanism. The CM500 engines are typically used in heavy-duty applications, where consistent and reliable cooling is essential. The Water Transfer Tube ensures that the coolant is distributed evenly, preventing hotspots and ensuring that the engine operates within its specified temperature range.

Integration and Functionality

The Water Transfer Tube is engineered to withstand the high pressures and temperatures associated with engine operation. It is typically made from high-quality materials that resist corrosion and degradation, ensuring a long service life. The tube’s design allows for efficient coolant flow, which is critical in both high-performance and heavy-duty applications.

In both the QSK45 and CM500 series, the Water Transfer Tube is integrated into the engine’s cooling system in a way that maximizes its effectiveness. This involves precise placement and secure connections to other components of the cooling system, ensuring that the coolant flows as intended without leaks or restrictions.

Importance in Engine Performance

The Water Transfer Tube is a key component in maintaining the engine’s performance and reliability. By ensuring that the engine remains within its optimal temperature range, it helps to prevent overheating, which can lead to engine damage and reduced lifespan. Additionally, efficient cooling contributes to better fuel efficiency and reduced emissions, making it an essential part of modern engine design.

Role of Part 4381249 Water Transfer Tube in Engine Systems

The 4381249 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with aftercoolers. This tube facilitates the movement of water between various components, ensuring optimal performance and longevity of the engine.

Integration with Plumbing Systems

In engine systems, the 4381249 Water Transfer Tube is meticulously integrated into the plumbing network. Its primary function is to transport water from the water reservoir to the aftercooler. This process is vital for maintaining the correct temperature and pressure within the engine, which in turn enhances efficiency and reduces the risk of overheating.

Function in Aftercooler Water Circulation

The aftercooler is a component designed to cool the compressed air from the turbocharger before it enters the engine’s combustion chamber. The 4381249 Water Transfer Tube plays a significant role here by ensuring a steady supply of water to the aftercooler. This continuous water flow is essential for dissipating heat effectively, which is a key factor in maintaining the engine’s performance under various operating conditions.

Enhanced Engine Performance

By efficiently transferring water to the aftercooler, the 4381249 Water Transfer Tube contributes to the overall performance of the engine. It aids in maintaining the ideal temperature for the compressed air, which leads to more efficient combustion and improved engine output. Additionally, this component helps in reducing thermal stress on engine components, thereby extending their operational life.

Reliable Component in Engine Maintenance

Incorporating the 4381249 Water Transfer Tube into engine systems is a strategic choice for reliability and maintenance. Its role in the water transfer process is straightforward yet indispensable, making it a component that demands attention during routine maintenance checks. Ensuring the tube is in good condition and properly connected is a fundamental aspect of maintaining the engine’s health and efficiency.

Conclusion

The Cummins 4381249 Water Transfer Tube is a vital component in the cooling systems of commercial trucks, particularly in Cummins engines like the QSK45 and CM500 series. Its role in facilitating efficient coolant circulation ensures optimal engine temperature, contributing to the engine’s performance, reliability, and longevity. Proper installation, maintenance, and attention to common issues are essential for maximizing the benefits of this part in heavy-duty applications.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004.

↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024.

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.