4007375

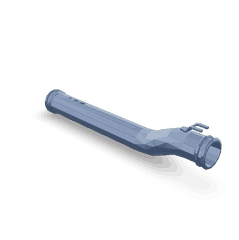

Water Transfer Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007375 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the engine.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit that allows coolant to flow between different parts of a truck’s cooling system. Its primary function is to ensure that the engine remains at an optimal operating temperature by circulating coolant from the engine to the radiator and back. This circulation helps dissipate heat generated by the engine, preventing overheating and potential damage 1.

Purpose of the 4007375 Water Transfer Tube

The 4007375 Water Transfer Tube is integral to the cooling system of a truck. It facilitates the transfer of coolant between the engine and the radiator. This ensures that the engine maintains a consistent temperature, which is crucial for efficient operation and durability. By providing a reliable pathway for coolant flow, the tube helps in evenly distributing heat across the engine components.

Key Features

This Cummins part is constructed with high-quality materials to ensure durability and efficient performance. It features robust connections that are designed to withstand the pressures and temperatures within the cooling system. The tube’s design includes specific elements that enhance its performance, such as smooth internal surfaces to promote efficient coolant flow and reinforced sections to prevent leaks.

Benefits

Using the Cummins 4007375 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the cooling efficiency of the engine. The tube’s durable construction ensures reliability under various operating conditions, reducing the likelihood of failures. Additionally, its design contributes to the overall efficiency of the cooling system, helping to maintain engine performance over time.

Installation Process

Installing this part requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include ensuring the cooling system is clean and free of debris. The necessary tools for installation may include wrenches and sealants. Following the manufacturer’s guidelines for installation is recommended to achieve the best results. This includes properly aligning the tube with its connections and ensuring all seals are intact.

Maintenance and Care

Routine maintenance of this Cummins part is important for ensuring its longevity and optimal performance. Regular inspections should be conducted to check for signs of wear, leaks, or blockages. Cleaning the tube and its connections as part of routine cooling system maintenance can help prevent issues. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures is advised.

Troubleshooting Common Issues

Common problems associated with water transfer tubes include leaks and blockages. Leaks may occur due to worn seals or damaged connections, while blockages can result from debris within the cooling system. Troubleshooting steps may involve inspecting the tube and connections for damage, cleaning the cooling system to remove debris, and replacing any worn or damaged components as necessary.

Compatibility and Application

This part is designed for use in specific types of trucks and engines. It is important to verify compatibility with the specific model or series of the truck to ensure proper fit and function.

Cummins Corporation Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its quality and reliability in the commercial truck industry. With a broad product range that includes engines, filtration, emissions solutions, and power generation equipment, Cummins has established a reputation for innovation and excellence. The company’s commitment to quality is reflected in its components, including the 4007375 Water Transfer Tube 2.

Role of Part 4007375 Water Transfer Tube in Engine Systems

The 4007375 Water Transfer Tube is integral to the efficient operation of both the primary engine system and the auxiliary cooling system.

In the primary engine system, the Water Transfer Tube facilitates the movement of coolant from the engine block to the radiator. This process ensures that the heat generated by the engine is effectively dissipated, maintaining optimal operating temperatures and preventing overheating. The tube connects to the engine’s water pump, which circulates the coolant through the engine passages, absorbing heat. The heated coolant is then directed to the radiator, where it releases heat to the ambient air, cooling down before returning to the engine. This continuous cycle is essential for the engine’s longevity and performance.

In the auxiliary cooling system, the Water Transfer Tube plays a similar yet specialized role. This system is designed to provide additional cooling for components that may not receive adequate cooling from the primary system alone, such as turbochargers, aftercoolers, or intercoolers. The tube ensures a consistent flow of coolant to these components, helping to maintain their efficiency and reliability. By integrating with the auxiliary cooling system, the Water Transfer Tube enhances the overall cooling capacity of the engine, ensuring that all critical components operate within their specified temperature ranges.

Conclusion

The effective functioning of the Water Transfer Tube in both systems underscores its importance in maintaining engine health and performance. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.