4006790

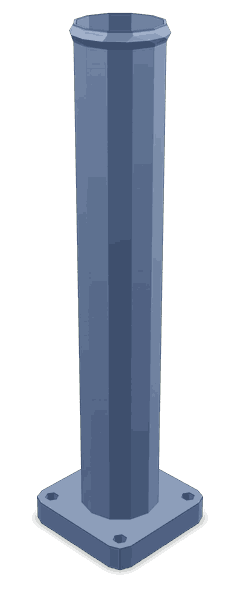

Water Transfer Tube

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4006790 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its purpose is to ensure that the engine maintains an optimal operating temperature, which is vital for performance and longevity. This part is integral to the cooling system, working in conjunction with other components to regulate engine temperature effectively 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of the engine cooling system. It plays a role in the system by directing coolant from the radiator to the engine block and other critical components that require cooling. The efficient circulation of coolant is important for dissipating heat generated by the engine, thereby maintaining engine temperature within specified limits and ensuring reliable operation 2.

Purpose of the 4006790 Water Transfer Tube

The specific role of the Cummins 4006790 Water Transfer Tube in a truck’s operation is to provide a pathway for coolant to travel from the radiator to the engine block and other areas that require cooling. This ensures that the engine does not overheat, which could lead to reduced performance or damage. By facilitating the smooth and consistent flow of coolant, this tube contributes to the overall efficiency and reliability of the engine 3.

Key Features

The Cummins 4006790 Water Transfer Tube is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand the pressure of the cooling system, enhancing its performance and durability over time 4.

Benefits

Using the Cummins 4006790 Water Transfer Tube offers several advantages. It provides improved engine cooling efficiency due to its design and material properties. The tube’s durability ensures longevity, reducing the need for frequent replacements. Its reliable performance contributes to the overall stability and efficiency of the truck’s cooling system 5.

Installation Process

Installing the Cummins 4006790 Water Transfer Tube requires careful attention to ensure a proper fit. The process involves disconnecting the old tube, cleaning the area, and securing the new tube in place using the appropriate tools and equipment. It is important to follow manufacturer guidelines to ensure that the tube is installed correctly and functions as intended within the cooling system 6.

Troubleshooting Common Issues

Common issues with the Cummins 4006790 Water Transfer Tube may include leaks or blockages. To address these problems, it is important to inspect the tube for signs of wear or damage, check connections for tightness, and ensure that the coolant flow is unobstructed. Troubleshooting steps may involve cleaning or replacing the tube if necessary to restore proper function 7.

Maintenance Tips

Regular maintenance of the Cummins 4006790 Water Transfer Tube is important to keep it in optimal condition. This includes periodic inspections for leaks or damage, cleaning the tube and connections, and monitoring the coolant level and condition. Following these practices helps ensure the tube continues to perform effectively and contributes to the longevity of the engine cooling system 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins is renowned in the commercial truck industry for its reliable and high-performance components. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 4006790 Water Transfer Tube, which is designed to meet the demanding requirements of commercial truck applications 9.

Water Transfer Tube (Part 4006790) in Cummins Engines

The Water Transfer Tube, identified as part 4006790, is a critical component in the cooling system of various Cummins engines. This part is integral to the efficient operation of the engine by facilitating the transfer of coolant between different parts of the engine block.

Application in Cummins Engines

The Water Transfer Tube is designed to fit seamlessly within the engine architecture of several Cummins models. Here are the engines where this part is applicable:

- QSK78 CM500

This part ensures that the coolant is properly circulated, maintaining optimal engine temperature and preventing overheating. The design and material of the Water Transfer Tube are engineered to withstand the high pressures and temperatures within the engine, ensuring durability and reliability 10.

Importance of the Water Transfer Tube

The Water Transfer Tube plays a pivotal role in the cooling system by:

- Ensuring even distribution of coolant throughout the engine.

- Preventing localized overheating by maintaining a consistent coolant flow.

- Contributing to the overall efficiency and longevity of the engine.

The integration of this part in the Cummins engines mentioned above highlights its importance in maintaining the engine’s performance and reliability 11.

Role of Part 4006790 Water Transfer Tube in Engine Systems

The part 4006790 Water Transfer Tube is an essential component in the auxiliary cooling system of various engine setups. Its primary function is to facilitate the efficient transfer of coolant between different parts of the engine system, ensuring optimal thermal management.

In the auxiliary cooling system, the Water Transfer Tube connects to the main coolant passages and auxiliary cooling components. It works in tandem with the thermostat, radiator, and water pump to maintain consistent coolant flow. This ensures that the engine operates within safe temperature ranges, preventing overheating and potential damage 12.

The Water Transfer Tube also interfaces with the heat exchanger, allowing for the dissipation of excess heat from the engine oil or transmission fluid. This integration is vital for maintaining the viscosity and performance of these fluids, which are crucial for the smooth operation of the engine and transmission 13.

Furthermore, the Water Transfer Tube plays a role in the operation of the charge air cooler (intercooler) in turbocharged engines. By transferring coolant to the intercooler, it helps in reducing the temperature of the compressed air before it enters the combustion chamber. This results in more efficient combustion and increased power output 14.

Conclusion

In summary, the 4006790 Water Transfer Tube is a key component in ensuring the reliable and efficient operation of the auxiliary cooling system, contributing to the overall performance and longevity of the engine 15.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL8.9 CM2880 L112. Bulletin Number 4358494.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.