This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

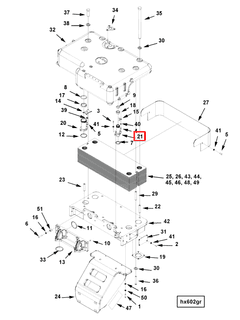

The Cummins 3969450 Water Transfer Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the transfer of coolant between the engine and the radiator, playing a role in maintaining optimal engine temperature. This part is significant in the operation of heavy-duty trucks as it contributes to the efficiency and reliability of the engine cooling system 1.

Function and Operation

The Water Transfer Tube operates within the truck’s cooling system by providing a conduit for coolant to flow from the engine to the radiator and back. This circulation helps dissipate heat generated by the engine, ensuring that it operates within safe temperature ranges. The tube is positioned to connect key components of the cooling system, allowing for efficient transfer of coolant 2.

Key Features

The design and construction of the Cummins 3969450 Water Transfer Tube include several features that enhance its performance. It is made from durable materials that can withstand the high temperatures and pressures of the cooling system. The tube features secure connection points that ensure a tight seal, preventing leaks. Additionally, its design may include reinforcements or specific shaping to optimize coolant flow and durability 3.

Benefits

The Cummins 3969450 Water Transfer Tube offers several advantages. It provides improved coolant flow, which contributes to more effective engine cooling. The tube’s durable construction enhances its longevity, reducing the need for frequent replacements. Furthermore, by ensuring efficient coolant circulation, it plays a role in maintaining overall engine efficiency and performance 4.

Installation and Compatibility

Proper installation of the Water Transfer Tube is important for its function and the overall health of the engine cooling system. Installation procedures should follow manufacturer guidelines to ensure secure and correct placement. It is designed to be compatible with specific truck models and engine types, ensuring a proper fit and function within the system 1.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube includes checking for signs of wear or damage, ensuring connections are secure, and looking for any leaks. Common issues may include blockages or leaks, which can be addressed by cleaning the tube or tightening connections as necessary. Regular inspections can help identify potential problems before they lead to more significant issues 2.

Safety Considerations

When working with the Water Transfer Tube, it is important to observe safety guidelines. This includes allowing the engine and coolant to cool before performing any maintenance to avoid burns from hot coolant. Additionally, ensuring that the cooling system is properly pressurized is important to prevent coolant loss and maintain system efficiency 3.

Cummins Overview

Cummins Inc. is a well-established manufacturer of diesel engines and related components, serving various industries including transportation, construction, and power generation. With a history of innovation and quality, Cummins has built a reputation for producing reliable and efficient engine components, including the 3969450 Water Transfer Tube 4.

Conclusion

The Cummins 3969450 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks. Its efficient design and durable construction contribute to the overall performance and reliability of the engine. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ ↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ ↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.