This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

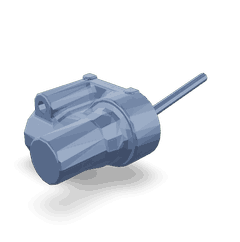

Water transfer connections are essential in the cooling systems of commercial truck engines, ensuring optimal engine performance and longevity. Cummins, a leader in the industry, is renowned for its commitment to quality and reliability. This article provides a comprehensive understanding of the Cummins Water Transfer Connection part #3649104, detailing its function, integration, and maintenance requirements.

Basic Concepts Related to Water Transfer Connections

A Water Transfer Connection is a critical component in the engine cooling system, facilitating the efficient transfer of coolant between various engine parts. This connection ensures proper coolant circulation, maintaining the engine’s temperature within safe operating limits. Proper water flow is vital for engine efficiency and longevity, preventing overheating and potential damage 1.

Purpose of the Cummins Water Transfer Connection Part #3649104

The Cummins Water Transfer Connection part #3649104 is designed to enhance the cooling system’s efficiency in truck engines. This part plays a crucial role in the overall operation of the engine by ensuring seamless coolant transfer. Its precise design and engineering contribute significantly to maintaining the engine’s optimal temperature, thereby enhancing performance and durability 2.

How the Cummins Water Transfer Connection Part #3649104 Works

The Water Transfer Connection part #3649104 functions by creating a secure and efficient pathway for coolant to flow between the engine block and other cooling system components. Proper installation and alignment are crucial to ensure that the coolant circulates without leaks or restrictions. An illustration showing the placement and interaction with other engine components would highlight its integration within the system.

Importance of Maintenance and Troubleshooting

Maintaining the Water Transfer Connection is vital to prevent common issues such as leaks, corrosion, and blockages. Regular inspections and cleaning can help avoid these problems. If issues arise, troubleshooting steps include checking for proper alignment, inspecting for wear or damage, and ensuring all connections are secure. Using genuine Cummins parts for replacements is imperative to maintain the system’s integrity and performance 3.

Cummins’ Commitment to Quality and Reliability

Cummins employs rigorous manufacturing processes and quality control measures to ensure the durability and performance of their parts. The company’s commitment to excellence is evident in the consistent reliability of their components in the field. Testimonials and case studies often highlight the superior performance and longevity of Cummins parts, reinforcing their reputation in the industry.

Expert Insights and Best Practices

Industry experts emphasize the importance of maintaining Water Transfer Connections to ensure engine efficiency and longevity. Best practices for engineers and mechanics include regular inspections, proper installation techniques, and the use of genuine parts. Fleet operators are advised to schedule regular maintenance checks to identify and address potential issues before they lead to significant problems.

Compatibility with Cummins Engines

K38 Engines

In the K38 engine series, the Water Transfer Connection part 3649104 is meticulously engineered to fit seamlessly within the engine’s cooling system architecture. This part ensures that coolant flows effectively from the radiator to the engine block and back, preventing overheating and maintaining the engine’s performance.

K50 Engines

Similarly, for the K50 engine series, the Water Transfer Connection part 3649104 plays a pivotal role in the engine’s cooling system. Its design is tailored to integrate perfectly with the K50’s cooling system, ensuring that the coolant is distributed evenly and efficiently throughout the engine. This helps in maintaining the engine’s efficiency and longevity.

Grouping of Engines

Both the K38 and K50 engines benefit from the use of the Water Transfer Connection part 3649104, as it is a crucial element in their cooling systems. The design of this part is standardized to fit these specific engine models, ensuring compatibility and reliability. Cummins has ensured that this part meets the stringent requirements of both engine series, providing a seamless fit and function.

Role of Part 3649104 Water Transfer Connection in Engine Systems

The Part 3649104 Water Transfer Connection is integral to the efficient operation of several key components within engine systems. This component facilitates the seamless transfer of water, which is essential for maintaining optimal performance and longevity of the engine.

Integration with Aftercooler Systems

In systems equipped with an aftercooler core, the Part 3649104 ensures that water is effectively circulated through the aftercooler plumbing. This circulation is vital for cooling the compressed air before it enters the combustion chamber, thereby enhancing engine efficiency and reducing the risk of overheating.

Coordination with Aftercooler Water Plumbing

The aftercooler water plumbing relies on the Part 3649104 to maintain a consistent water flow. This consistent flow is necessary for the effective regulation of temperatures within the aftercooler, which directly impacts the performance and reliability of the engine.

Interaction with Camshaft and Gear

Although the camshaft and gear are primarily mechanical components, their optimal operation is influenced by the engine’s overall temperature. The Part 3649104 plays a supporting role by helping to manage the engine’s thermal environment, thus indirectly contributing to the smooth functioning of these components.

Support for Injectors

The performance of injectors is sensitive to temperature variations. The Part 3649104 assists in maintaining a stable thermal environment by ensuring efficient water transfer, which helps in precise fuel delivery and combustion, ultimately enhancing engine performance.

Contribution to LB LTA Connections

In systems with LB LTA connections, the Part 3649104 ensures that water is properly routed to and from these connections. This proper routing is essential for the effective cooling of various engine parts, contributing to the overall durability and performance of the engine.

Role in Oil Control Valve Operation

The oil control valve relies on stable engine temperatures to function correctly. The Part 3649104 aids in maintaining this stability by ensuring efficient water transfer, which helps in regulating the engine’s thermal conditions.

Enhancement of Performance Parts

For engines equipped with performance parts, the Part 3649104 is particularly important. It ensures that these high-performance components operate within their optimal temperature ranges, thereby maximizing their efficiency and longevity.

Overall Impact on Engine Plumbing

The Part 3649104 is a key element in the engine’s plumbing system. Its role in facilitating efficient water transfer is essential for the proper functioning of various engine components, contributing to the engine’s overall performance and reliability.

Conclusion

In summary, the Cummins Water Transfer Connection part #3649104 is a critical component in the engine cooling system, essential for maintaining optimal engine performance and longevity. Proper maintenance and troubleshooting are key to ensuring its efficient operation. This article serves as a reliable resource for understanding and managing the Water Transfer Connection, emphasizing the importance of using genuine Cummins parts and following best practices for maintenance and installation.

-

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018.

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ -

Advances in Engine and Powertrain Research and Technology, Tigran Parikyan Ed, Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.