This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3648001 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the vehicle 1.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit that allows coolant to flow between different parts of a truck’s cooling system. It operates on the principle of fluid dynamics, where coolant is circulated to absorb heat from the engine and dissipate it through the radiator. This process is fundamental to preventing engine overheating and ensuring consistent performance 2.

Purpose of the 3648001 Water Transfer Tube

This Cummins part is integral to the truck’s cooling system. It functions by transferring coolant from the engine to the radiator and back, playing a role in the heat exchange process that keeps the engine within its optimal operating temperature range.

Key Features

This part is constructed from durable materials that resist corrosion and withstand high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Unique attributes such as reinforced sections enhance its performance under the demanding conditions of commercial truck operation.

Benefits

The use of the Water Transfer Tube contributes to improved coolant flow, which enhances engine cooling efficiency. This, in turn, supports overall engine performance and can extend the engine’s operational life by maintaining consistent temperatures and reducing thermal stress.

Installation Process

Installing this part requires attention to detail to ensure a proper fit. The process involves preparing the engine compartment, using the appropriate tools for secure fastening, and following manufacturer guidelines to connect the tube to the engine and radiator. Best practices include checking for proper alignment and ensuring all connections are tight to prevent leaks.

Common Issues and Troubleshooting

Water transfer tubes may encounter issues such as leaks or blockages. Troubleshooting these problems involves inspecting the tube for signs of wear or damage, checking connections for tightness, and ensuring that the coolant flow is unobstructed. Addressing these issues promptly can prevent more significant cooling system failures.

Maintenance Tips

Regular maintenance of this Cummins part includes periodic inspections for wear and corrosion, as well as cleaning to remove any buildup that could impede coolant flow. Adhering to recommended inspection intervals and performing routine checks can help maintain the tube’s performance and longevity.

Cummins Overview

Cummins Inc. is a leader in the design and manufacture of diesel engines, including components like the 3648001 Water Transfer Tube. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability in the commercial truck industry. The company’s product range reflects its expertise in engine technology and its dedication to meeting the needs of professional drivers and fleet operators 3.

Role of Part 3648001 Water Transfer Tube in Engine Systems

The Water Transfer Tube, identified as part 3648001, is integral to the efficient operation of various engine components. Its primary function is to facilitate the movement of coolant within the engine system, ensuring optimal thermal management.

Interaction with Camshaft and Gear

The Water Transfer Tube works in conjunction with the camshaft and gear assembly. As the camshaft rotates, driven by the crankshaft, it actuates the valves in a precise sequence. This part ensures that the camshaft and gear assembly remain at an optimal temperature, preventing overheating and potential warping or seizing of the components.

Support for Injectors

Fuel injectors are sensitive to temperature variations. The Water Transfer Tube plays a role in maintaining a stable thermal environment around the injectors. This stability ensures that the injectors operate within their specified parameters, promoting efficient fuel delivery and combustion.

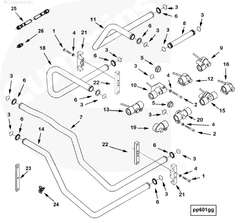

Integration with Left Bank Aftercooler Plumbing

In turbocharged engines, the aftercooler (or intercooler) is vital for reducing the temperature of compressed air before it enters the combustion chamber. The Water Transfer Tube is often part of the left bank aftercooler plumbing system. It helps in circulating coolant through the aftercooler, enhancing the efficiency of the cooling process and ensuring that the air-fuel mixture entering the cylinders is at an optimal temperature.

Contribution to Overall Performance

The consistent and reliable operation of the Water Transfer Tube directly influences the performance of the engine. By maintaining appropriate temperatures across critical components, it helps in achieving better fuel efficiency, reduced emissions, and enhanced overall engine performance.

Conclusion

In summary, the Water Transfer Tube (part 3648001) is a key component in the thermal management system of an engine, interacting with and supporting the function of various other components to ensure smooth and efficient operation.

-

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.