This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

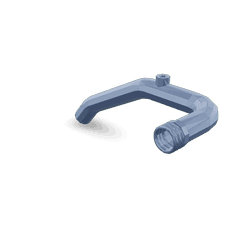

The Cummins 3648000 Water Transfer Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the efficient transfer of coolant within the truck’s cooling system. This part plays a role in maintaining optimal engine temperature by ensuring a consistent flow of coolant between critical components 1.

Function and Operation

The Water Transfer Tube operates as a conduit within the truck’s cooling system. It connects the radiator, engine block, and thermostat, allowing coolant to circulate effectively. This circulation helps dissipate heat generated by the engine, preventing overheating. The tube’s design ensures that coolant flows smoothly, enhancing the overall efficiency of the cooling process 2.

Key Features

The Cummins 3648000 Water Transfer Tube is constructed from durable materials that resist corrosion and withstand high temperatures. It features secure connection points that ensure a tight seal, minimizing the risk of leaks. The tube’s design includes reinforced sections to handle the pressure exerted by the coolant system, contributing to its longevity and reliability 3.

Benefits

The use of the Cummins 3648000 Water Transfer Tube offers several advantages. It contributes to improved cooling efficiency by ensuring a consistent and reliable flow of coolant. The robust construction reduces the likelihood of leaks, which can lead to engine damage. Additionally, its durable materials and design enhance the component’s lifespan, providing long-term value for truck operators.

Installation and Compatibility

Proper installation of the Water Transfer Tube is vital for its effective operation. It should be fitted according to the manufacturer’s guidelines, using the appropriate tools and taking necessary precautions. Compatibility with specific truck models and engine types should be verified to ensure optimal performance and integration within the cooling system.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube involves inspecting for signs of wear or damage and ensuring connections remain secure. Common issues may include leaks or blockages, which can be diagnosed through visual inspection and pressure testing. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the cooling system.

Safety Considerations

When working with the Water Transfer Tube, it is important to observe safety guidelines. This includes allowing the engine to cool before beginning any maintenance or repair work to avoid burns from hot components. Additionally, caution should be exercised when working with pressurized systems to prevent injury from sudden releases of coolant.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of engine and component solutions. With a history of innovation and quality, Cummins products are designed to meet the demanding requirements of commercial transportation, providing reliable performance and durability for truck operators.

Water Transfer Tube (Part 3648000) in Cummins Engines

The Water Transfer Tube (part number 3648000) manufactured by Cummins is a critical component in the cooling system of various Cummins engines. This part ensures efficient heat transfer, maintaining optimal engine temperatures and preventing overheating.

K50 Series Engines

In the K50 series engines, the Water Transfer Tube is integral to the engine’s cooling system. It facilitates the transfer of coolant between different parts of the engine, ensuring that heat is evenly distributed and managed. This tube connects the water pump to the radiator, allowing coolant to flow through the engine block and back to the radiator for cooling.

The precise fit and design of the Water Transfer Tube in the K50 engines are crucial for maintaining the engine’s performance and longevity. Its placement and connection points are engineered to withstand the high pressures and temperatures typical of engine operation.

The Water Transfer Tube’s role in the K50 engines is to maintain a consistent coolant flow, which is essential for the engine’s thermal management. This ensures that the engine operates within its optimal temperature range, enhancing efficiency and reducing the risk of thermal stress on engine components.

Role of Part 3648000 Water Transfer Tube in Engine Systems

The Part 3648000 Water Transfer Tube is an essential component in the orchestration of various engine systems, ensuring optimal performance and efficiency. Its primary function is to facilitate the movement of water within the engine, which is integral to several key processes.

Interaction with the Camshaft and Gear

In engines where the camshaft and gear system is employed, the water transfer tube plays a supportive role. It ensures that the camshaft and gear assembly remains adequately cooled. This is particularly important in high-performance engines where the camshaft and gear operate under significant stress and heat. The consistent flow of water helps maintain the integrity and longevity of these components.

Support for Injectors

The injectors in an engine are responsible for delivering fuel into the combustion chamber. The water transfer tube assists in maintaining the temperature of the injectors, ensuring they operate within their specified parameters. Proper cooling prevents issues such as fuel vaporization before combustion, which can lead to inefficient engine performance.

Contribution to Overall Performance

The water transfer tube is a silent contributor to the overall performance of the engine. By ensuring that critical components remain at optimal temperatures, it helps in achieving consistent engine performance. This is especially noticeable in high-stress scenarios where engine components are pushed to their limits.

Integration with Right Bank Aftercooler Plumbing

In engines equipped with aftercoolers, the water transfer tube is integral to the right bank aftercooler plumbing. It aids in the cooling of compressed air before it enters the combustion chamber. This process is vital for improving engine efficiency and power output. The tube ensures that the aftercooler operates effectively, thereby enhancing the engine’s overall performance.

General Component Support

Beyond specific components, the water transfer tube supports various parts within the engine. It helps in maintaining a balanced thermal environment, which is essential for the reliable operation of all engine components. This balanced environment ensures that parts function as intended, contributing to the engine’s durability and efficiency.

Conclusion

The Cummins 3648000 Water Transfer Tube is a vital component in the cooling systems of commercial trucks and Cummins engines. Its design and construction ensure efficient coolant flow, contributing to optimal engine temperature management and overall performance. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components (Springer, 2014).

↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition (Elsevier Ltd, 2011).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.