This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3647866 Water Transfer Tube is a component designed for use in commercial trucks. Its primary function is to facilitate the efficient transfer of coolant within the engine’s cooling system. This ensures that the engine operates within optimal temperature ranges, thereby enhancing performance and longevity 1.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit within a truck’s cooling system that allows coolant to circulate between various components. This circulation is vital for dissipating heat generated by the engine. By maintaining a consistent coolant flow, the tube helps regulate engine temperature, which is essential for the engine’s efficient operation and durability 2.

Purpose of the 3647866 Water Transfer Tube

The Cummins 3647866 Water Transfer Tube specifically plays a role in the truck’s cooling system by directing coolant from the engine to the radiator and back. This continuous flow helps in dissipating heat, ensuring that the engine does not overheat. The tube is engineered to handle the pressures and temperatures within the cooling system, providing reliable performance 3.

Key Features

The Cummins 3647866 Water Transfer Tube is constructed from durable materials that can withstand high temperatures and pressures. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance durability and prevent kinking or damage during operation 4.

Benefits

Using the Cummins 3647866 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the engine’s cooling efficiency. This results in better engine protection against overheating and potential damage. Furthermore, the tube’s robust construction contributes to increased reliability and longevity of the cooling system 5.

Installation and Integration

Installing the Cummins 3647866 Water Transfer Tube involves several steps. First, ensure that the engine is cool and the cooling system is drained. Next, remove the old tube and inspect the fittings for any damage. Install the new tube, ensuring all connections are secure and tightened to the manufacturer’s specifications. Finally, refill the cooling system with the appropriate coolant and check for leaks 6.

Common Issues and Troubleshooting

Common issues with water transfer tubes include leaks, blockages, and damage from wear and tear. Leaks can often be traced to loose connections or deteriorated fittings. Blockages may result from debris or coolant deposits. Regular inspections and maintenance can help identify these issues early. If a leak is detected, the tube should be replaced. For blockages, flushing the cooling system may resolve the issue 7.

Maintenance Tips

To ensure the optimal performance of the Cummins 3647866 Water Transfer Tube, regular maintenance is recommended. This includes periodic inspections for signs of wear, leaks, or damage. Cleaning the tube and its connections can prevent buildup that may lead to blockages. Additionally, following the manufacturer’s guidelines for coolant replacement and system flushing will help maintain efficient coolant flow and engine temperature regulation 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. Their product range includes a variety of parts and systems designed to enhance the efficiency and durability of commercial vehicles 9.

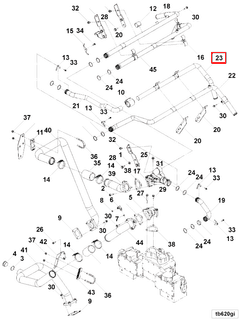

Role of Part 3647866 Water Transfer Tube in Engine Systems

The Part 3647866 Water Transfer Tube is integral to the operation of both the auxiliary cooling system and the main engine cooling system.

In the Auxiliary Cooling System, the Water Transfer Tube facilitates the movement of coolant from the auxiliary cooling pump to the auxiliary heat exchanger. This process ensures that components such as turbochargers, aftercoolers, and intercoolers maintain optimal operating temperatures. The efficient transfer of coolant helps prevent overheating, which can lead to reduced performance and potential damage to these sensitive components.

Within the Main Engine Cooling System, the Water Transfer Tube plays a similar role by ensuring consistent coolant flow between the engine block and the main heat exchanger. This steady flow is essential for dissipating heat generated by the combustion process, thereby maintaining the engine’s thermal stability.

Additionally, the Water Transfer Tube interacts with the System components, including thermostats and temperature sensors, to regulate coolant flow based on engine load and temperature conditions. This interaction ensures that the engine operates within its designed thermal envelope, enhancing durability and performance.

Overall, the Part 3647866 Water Transfer Tube is a key component in maintaining the thermal management of both auxiliary and main engine systems, contributing to the overall efficiency and reliability of the engine 10.

Conclusion

The Cummins 3647866 Water Transfer Tube is a critical component in the cooling systems of commercial trucks. Its role in facilitating efficient coolant flow ensures that engines operate within optimal temperature ranges, enhancing performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Cummins Inc. (n.d.). About Cummins. Retrieved from https://www.cummins.com/about

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.