3647842

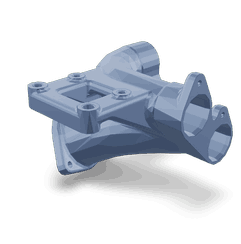

Water Transfer Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Water Transfer Connection 3647842, manufactured by Cummins, is a critical component in the efficient operation of heavy-duty trucks. This part is essential for maintaining the engine’s cooling system, ensuring optimal performance and reliability. Understanding its function and significance is beneficial for fleet operators and technicians.

Basic Concepts of Water Transfer Connection

Water transfer connections in heavy-duty trucks are designed to facilitate the movement of coolant between different parts of the engine cooling system. These connections ensure that the engine remains at an optimal operating temperature, which is vital for engine performance and longevity. Consistent coolant flow helps prevent overheating and associated engine damage 1.

Purpose of the Water Transfer Connection 3647842

The Water Transfer Connection 3647842 plays a specific role within the engine cooling system of a truck. It is responsible for connecting various coolant pathways, ensuring that coolant is efficiently distributed throughout the engine. This part helps maintain a stable engine temperature, which is crucial for the engine’s overall performance and durability 2.

Key Features

The Water Transfer Connection 3647842 is constructed from high-quality materials, ensuring durability and reliability in demanding operating conditions. Its design includes precise fittings and seals that prevent coolant leaks and maintain efficient coolant flow. Additionally, the part is engineered to withstand high pressures and temperatures, making it suitable for use in heavy-duty applications 3.

Benefits

The advantages of using the Water Transfer Connection 3647842 include improved cooling efficiency, which contributes to better engine performance and longevity. The reliable design of this part reduces the likelihood of coolant leaks and system failures, leading to lower maintenance costs and increased uptime for fleet operators. Additionally, the high-quality construction ensures that the part can endure the rigors of heavy-duty use, providing long-term value.

Installation Process

Installing the Water Transfer Connection 3647842 requires careful attention to detail to ensure proper integration into the truck’s cooling system. The process involves disconnecting the old part, cleaning the mating surfaces, and securely attaching the new connection. It is important to follow the manufacturer’s guidelines to ensure a proper fit and seal, which will prevent coolant leaks and ensure efficient coolant flow.

Common Issues and Troubleshooting

Typical problems with the Water Transfer Connection 3647842 may include coolant leaks, improper fitting, or blockages within the connection. Troubleshooting these issues involves inspecting the part for signs of wear or damage, ensuring that all connections are secure, and checking for any obstructions in the coolant pathways. Addressing these issues promptly can help maintain the efficiency and reliability of the engine cooling system.

Maintenance Tips

To ensure the optimal performance and longevity of the Water Transfer Connection 3647842, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the connection and its surrounding areas can prevent buildup that may impede coolant flow. Additionally, following the manufacturer’s recommended maintenance intervals will help identify and address potential issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product offerings include engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of heavy-duty applications.

Role of Part 3647842 Water Transfer Connection in Engine Systems

The Water Transfer Connection 3647842 is an essential component in the integration and operation of various engine systems, particularly within the auxiliary cooling system. This component facilitates the efficient transfer of coolant between the primary engine cooling system and the auxiliary cooling system.

In the context of the auxiliary cooling system, the Water Transfer Connection ensures that coolant is effectively circulated to and from the auxiliary cooler. This is particularly important in high-performance or high-stress engine environments where additional cooling is required to maintain optimal operating temperatures. The connection allows for the seamless integration of the auxiliary cooler into the existing cooling loop, enhancing the overall cooling efficiency of the engine.

Furthermore, the Water Transfer Connection plays a significant role in maintaining the balance of coolant flow. It ensures that the coolant is distributed evenly, preventing hotspots and ensuring that all critical engine components receive adequate cooling. This is especially important in engines with complex cooling requirements, where precise coolant management is necessary to prevent overheating and ensure longevity.

Additionally, the integration of this component within the system allows for easier maintenance and servicing. By providing a dedicated connection point, mechanics can more easily access and service the auxiliary cooling components without disrupting the primary cooling system. This enhances the overall serviceability of the engine, reducing downtime and improving operational efficiency.

Conclusion

The Water Transfer Connection 3647842 is a key element in the effective operation of engine cooling systems, particularly within the auxiliary cooling setup. Its role in facilitating coolant transfer, maintaining flow balance, and enhancing serviceability underscores its importance in modern engine designs.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.