This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3646051 Water Transfer Tube is a component designed for use in the cooling systems of heavy-duty trucks. Its purpose is to facilitate the efficient transfer of coolant between the engine block and the radiator, ensuring that the engine operates within optimal temperature ranges. This part is integral to maintaining the overall performance and longevity of the engine by contributing to effective thermal management 1.

Function and Operation

The Water Transfer Tube operates by channeling coolant from the engine block to the radiator and back. This process involves interaction with several key components within the cooling system. Once the engine reaches operating temperature, the thermostat opens, allowing coolant to flow through the tube to the radiator where it is cooled. The cooled coolant then returns to the engine block to absorb more heat, creating a continuous cycle that helps regulate engine temperature. The tube’s design ensures minimal resistance to coolant flow, enhancing the efficiency of the cooling process 2.

Key Features

This Cummins part is constructed from durable materials that resist corrosion and withstand high temperatures and pressures typical in heavy-duty truck engines. It features secure connection types that ensure a tight seal, preventing coolant leaks. The design of the tube includes smooth internal passages to facilitate unimpeded coolant flow, and it may incorporate reinforcement in critical areas to enhance durability under operational stress 3.

Benefits

The use of the 3646051 offers several advantages. It contributes to improved coolant flow within the system, which enhances engine cooling efficiency. This efficient cooling can lead to better engine performance and potentially extend the engine’s operational life by reducing thermal stress. Additionally, the tube’s robust construction and design features support its reliability and longevity in demanding applications.

Installation and Compatibility

Proper installation of the Water Transfer Tube involves several steps to ensure it functions correctly within the cooling system. Preparatory steps may include draining the coolant, removing the old tube, and inspecting the mating surfaces for cleanliness and integrity. Tools required for installation might include wrenches for securing connections and a coolant pressure tester to check for leaks post-installation. It is important to verify compatibility with specific truck models and engine types to ensure optimal performance and fit.

Maintenance and Troubleshooting

Routine maintenance of the 3646051 is vital for its continued efficient operation. This includes regular inspection intervals to check for signs of wear, corrosion, or leaks. Cleaning procedures may involve flushing the cooling system to remove any contaminants that could impede coolant flow or cause blockages. Common issues such as leaks or blockages can often be identified through visual inspection and pressure testing. Troubleshooting tips include checking connection seals for integrity and ensuring that the tube is free from obstructions that could hinder coolant flow.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction in the automotive and heavy-duty truck industry. The company’s commitment to advancing technology and improving product performance underscores its position as a trusted manufacturer of automotive components.

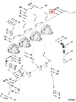

Role of Part 3646051 Water Transfer Tube in Turbocharger Plumbing

The Water Transfer Tube, identified by part number 3646051, is integral to the efficient operation of turbocharger plumbing systems. This component facilitates the circulation of cooling water within the turbocharger, ensuring optimal performance and longevity of the system.

Integration with Turbocharger Plumbing

-

Coolant Circulation: The Water Transfer Tube is designed to route coolant from the engine’s cooling system to the turbocharger. This circulation helps manage the high temperatures generated during operation, preventing overheating and potential damage to the turbocharger components.

-

Thermal Management: By maintaining a consistent flow of coolant, the tube assists in thermal management. This is particularly important in high-performance engines where turbochargers operate under extreme conditions. Effective cooling prolongs the lifespan of the turbocharger and enhances overall engine efficiency.

-

Pressure Regulation: The tube also plays a role in regulating the pressure within the cooling system. Proper pressure management is essential to avoid leaks and ensure that the coolant effectively transfers heat away from the turbocharger.

-

System Integrity: The Water Transfer Tube contributes to the integrity of the turbocharger plumbing by providing a reliable connection between the engine’s cooling system and the turbocharger. This ensures that coolant is delivered precisely where it is needed, without interruptions or reductions in flow.

-

Maintenance and Serviceability: The design of the Water Transfer Tube allows for easier maintenance and serviceability. Engineers and mechanics can quickly inspect, replace, or repair the tube if necessary, minimizing downtime and ensuring that the turbocharger system remains operational.

Conclusion

In summary, the Water Transfer Tube (part 3646051) is a key component in turbocharger plumbing, essential for maintaining the performance and reliability of the turbocharger within the engine system. Its role in coolant circulation, thermal management, pressure regulation, system integrity, and maintenance underscores its importance in the efficient operation of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.