This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3645996 Water Transfer Tube is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the transfer of coolant between the engine and the radiator. This transfer is vital for maintaining optimal engine temperature, which is important for the efficient and reliable performance of the truck 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a component found in a truck’s cooling system. Its general function is to transport coolant from the engine to the radiator and back. This process helps regulate the engine’s temperature by dissipating heat through the radiator. The tube operates as part of a closed-loop system, ensuring that coolant is continuously circulated to absorb and transfer heat away from the engine 2.

Purpose of the Cummins 3645996 Water Transfer Tube

The Cummins 3645996 Water Transfer Tube plays a role in the truck’s cooling system by transferring coolant between the engine and radiator. This transfer helps maintain the engine at an optimal operating temperature. By ensuring efficient coolant flow, the tube contributes to the overall cooling efficiency of the engine, which is important for the engine’s performance and longevity 3.

Key Features

The Cummins 3645996 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is made from durable materials that can withstand the high temperatures and pressures within the cooling system. The tube’s design ensures a secure fit within the cooling system, minimizing the risk of leaks. Additionally, its construction allows for efficient coolant flow, which is important for effective heat dissipation 4.

Benefits

The Cummins 3645996 Water Transfer Tube offers several benefits. It provides improved coolant flow, which enhances the engine’s cooling efficiency. This efficient cooling can contribute to better overall engine performance and may help extend the engine’s lifespan by preventing overheating. The tube’s design and materials also ensure durability and reliability under the demanding conditions of commercial truck operation.

Installation and Integration

Installing the Cummins 3645996 Water Transfer Tube involves fitting it into the truck’s cooling system in place of the existing tube. This process requires careful alignment and securing to ensure a proper seal and efficient coolant flow. Specific requirements may include ensuring the system is free of debris and that all connections are tight to prevent leaks.

Common Issues and Troubleshooting

Common issues with the Cummins 3645996 Water Transfer Tube may include leaks or blockages. Leaks can occur due to improper installation or wear over time, while blockages may result from debris within the cooling system. Troubleshooting steps include inspecting the tube and connections for signs of wear or damage, ensuring all connections are secure, and flushing the cooling system to remove any debris that may be causing blockages.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 3645996 Water Transfer Tube, regular maintenance is recommended. This includes inspecting the tube and connections for signs of wear or damage, ensuring all connections are secure, and flushing the cooling system periodically to remove debris. Replacement guidelines should be followed if the tube shows signs of significant wear or if leaks are detected.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in engine and component manufacturing. With a history of producing reliable and high-performance engines and parts, Cummins has built a reputation for excellence. The company’s focus on research and development ensures that its products, including the 3645996 Water Transfer Tube, meet the demanding requirements of commercial truck applications.

Role of Part 3645996 Water Transfer Tube in Engine Systems

The 3645996 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with aftercoolers. This tube is integral to the plumbing system, facilitating the movement of water between various components to ensure optimal engine performance and longevity.

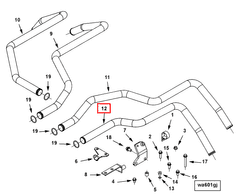

Integration with Plumbing Systems

In the context of engine plumbing, the 3645996 Water Transfer Tube serves as a conduit for water circulation. It connects to various points within the plumbing network, allowing for the regulated flow of water to critical areas. This ensures that all components receive the necessary cooling and lubrication, preventing overheating and potential damage.

Function in Aftercooler Water Systems

The aftercooler is a device used to cool the air charge entering the engine, enhancing efficiency and power output. The 3645996 Water Transfer Tube plays a significant role in this process by transferring water to and from the aftercooler. It ensures that the aftercooler maintains the appropriate temperature, which is vital for the efficient compression and expansion cycles within the engine.

By effectively managing the water flow, the tube helps in maintaining the desired pressure and temperature levels, contributing to the overall performance and reliability of the engine system.

Conclusion

The Cummins 3645996 Water Transfer Tube is a critical component in the cooling systems of commercial trucks and engines. Its role in facilitating efficient coolant flow is essential for maintaining optimal engine temperature, ensuring reliable performance, and extending engine lifespan. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.