3644497

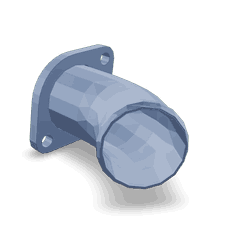

Water Transfer Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3644497 Water Transfer Tube is designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. It ensures that the engine maintains optimal operating temperatures by circulating coolant between the engine block, radiator, and other critical components. This part is integral to the overall cooling system, contributing to the engine’s performance and longevity 1.

Function and Operation

The Water Transfer Tube directs coolant flow from the engine block to the radiator and back. This circulation is vital for dissipating heat generated by the engine. The tube interacts with several components, including the radiator, engine block, and thermostat. As the engine operates, the thermostat regulates the flow of coolant based on the engine’s temperature. When the engine reaches operating temperature, the thermostat opens, allowing coolant to flow through the tube to the radiator, where it is cooled before returning to the engine block. This continuous cycle helps maintain the engine within its optimal temperature range 2.

Key Features

The Cummins 3644497 Water Transfer Tube is constructed from durable materials designed to withstand the high temperatures and pressures within the engine cooling system. It features robust connections that ensure a secure fit and reliable coolant flow. The design includes precise engineering to enhance performance and durability, with smooth internal passages that minimize resistance to coolant flow. Additionally, the tube is crafted to be resistant to corrosion and wear, ensuring long-term reliability in demanding operating conditions 3.

Benefits

The Cummins 3644497 Water Transfer Tube offers several advantages. It contributes to improved cooling efficiency by ensuring consistent and reliable coolant flow. This enhancement helps prevent overheating, which can lead to engine damage. The tube’s design reduces the risk of leaks, maintaining the integrity of the cooling system. Furthermore, by ensuring efficient coolant circulation, the tube supports enhanced overall engine performance, contributing to the truck’s reliability and efficiency.

Installation Considerations

When installing the Cummins 3644497 Water Transfer Tube, it is important to follow recommended procedures to ensure proper fit and function. Necessary tools include wrenches for securing connections and a coolant system pressure tester to check for leaks post-installation. It is advisable to replace any gaskets or seals during installation to prevent future leaks. Common pitfalls to avoid include over-tightening connections, which can damage threads, and not properly bleeding the cooling system, which can lead to air pockets and reduced efficiency.

Maintenance and Troubleshooting

Regular maintenance of the Water Transfer Tube is crucial for ensuring optimal performance. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections as part of routine coolant system maintenance can prevent buildup that might impede coolant flow. Common issues such as leaks or blockages can often be identified through visual inspection and pressure testing. Troubleshooting steps may involve replacing damaged sections, ensuring connections are secure, and flushing the cooling system to remove contaminants.

Manufacturer Information

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its high-quality engines and components. With a history of innovation and excellence, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation for reliability and performance is built on a commitment to engineering excellence and customer satisfaction.

Application in Cummins Engines

QSK78 Series

- QSK78 CM500: The Water Transfer Tube in the QSK78 CM500 engine is designed to ensure efficient coolant flow, which is essential for maintaining the engine’s thermal balance. This tube connects the water pump to other critical components, ensuring that the coolant circulates effectively, thereby preventing overheating and maintaining engine performance.

QSK60 Series

- QSK60 CM2350: In the QSK60 CM2350 engine, the Water Transfer Tube is equally important. It ensures that the coolant is evenly distributed throughout the engine, which is crucial for the longevity and reliability of the engine. This part is engineered to withstand high pressures and temperatures, ensuring durability and consistent performance.

QSK50 Series

- QSK50 CM2300: The Water Transfer Tube in the QSK50 CM2300 engine is designed to handle the specific demands of this engine model. It is a key component in the cooling system, ensuring that the engine operates within its optimal temperature range. This tube is engineered for precision and reliability, contributing to the overall efficiency of the engine.

QSK38 Series

- QSK38 CM2250: In the QSK38 CM2250 engine, the Water Transfer Tube plays a vital role in the cooling system. It ensures that the coolant is effectively transferred between the engine block and other components, maintaining the engine’s thermal efficiency. This part is designed to provide a reliable and durable solution for the engine’s cooling needs.

Importance of the Water Transfer Tube

The Water Transfer Tube is essential for the proper functioning of the engine’s cooling system. It ensures that the coolant is evenly distributed, which helps in maintaining the engine’s temperature within the optimal range. This component is designed to withstand the high pressures and temperatures associated with engine operation, ensuring longevity and reliability. Proper maintenance and timely replacement of this part are crucial for the overall health and performance of the engine.

Role of Part 3644497 Water Transfer Tube in Engine Systems

The part 3644497 Water Transfer Tube is an essential component in the auxiliary cooling system of various engine setups. Its primary function is to facilitate the efficient transfer of coolant between the engine and the auxiliary cooling system.

In the auxiliary cooling system, the Water Transfer Tube connects to the engine’s coolant passages, allowing coolant to flow from the engine to the auxiliary cooler. This setup ensures that the engine maintains optimal operating temperatures, even under demanding conditions. The tube works in conjunction with the thermostat, water pump, and radiator to regulate coolant flow and temperature.

The auxiliary cooling system often includes additional components such as the auxiliary radiator, heat exchanger, and cooling fans. The Water Transfer Tube plays a key role in this system by providing a dedicated pathway for coolant circulation. This helps in dissipating excess heat generated by the engine, thereby enhancing the overall efficiency and reliability of the cooling process.

Conclusion

The Cummins 3644497 Water Transfer Tube is a critical component in the cooling systems of heavy-duty engines, ensuring efficient coolant circulation and maintaining optimal engine temperatures. Its durable construction, precise engineering, and reliable performance make it essential for the longevity and efficiency of the engine. Proper installation, maintenance, and timely replacement are vital for the overall health and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.