This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3643078 Water Transfer Tube is a critical component in the cooling systems of heavy-duty trucks. It facilitates the efficient transfer of coolant between the engine and the radiator, ensuring optimal engine temperature and performance. This part is essential for maintaining the engine’s longevity by contributing to effective heat management.

Function and Operation

The Water Transfer Tube channels coolant from the engine block to the radiator and back. This process involves interaction with several key components within the cooling system. Coolant, after absorbing heat from the engine, is directed through the tube to the radiator where it releases heat into the ambient air. The now-cooled coolant returns to the engine block to absorb more heat, creating a continuous cycle that helps regulate engine temperature. The tube works in conjunction with the thermostat, which controls the flow of coolant based on engine temperature, ensuring that the engine reaches and maintains its optimal operating temperature 1.

Key Features

This Cummins part is constructed from durable materials designed to withstand the high temperatures and pressures within the engine cooling system. It features robust connection points that ensure a secure fit and prevent leaks. The design of the tube includes smooth internal passages that minimize resistance to coolant flow, enhancing the efficiency of heat transfer. Additionally, the tube is engineered to be resistant to corrosion and scaling, which are common issues in cooling systems, thereby contributing to its longevity and reliability 2.

Benefits

The use of the Cummins 3643078 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the efficiency of heat dissipation from the engine. This results in more stable engine temperatures, even under demanding operating conditions. The tube’s design and construction contribute to increased reliability, reducing the likelihood of leaks and failures. Moreover, its resistance to corrosion and scaling helps maintain the integrity of the cooling system over time, leading to lower maintenance requirements and extended component life 3.

Installation and Compatibility

Proper installation of the Water Transfer Tube is crucial for ensuring its effectiveness and the overall efficiency of the cooling system. Installation should follow manufacturer guidelines to ensure correct fitment and function. It is important to verify that all connections are secure and that the tube is properly aligned within the system. Compatibility with specific truck models and engine types should be confirmed prior to installation to ensure optimal performance and integration within the existing cooling system architecture.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube involves regular inspection for signs of wear, corrosion, or leaks. It is advisable to check the condition of the connections and the integrity of the tube during scheduled maintenance intervals. Common issues that may arise include leaks at connection points or blockages within the tube, which can impede coolant flow. Diagnostic steps for troubleshooting may include visual inspection, pressure testing, and flow analysis. Potential solutions range from tightening connections to replacing the tube if damage is detected.

Performance in Various Conditions

The Cummins 3643078 Water Transfer Tube is designed to perform effectively under a range of operating conditions. In extreme temperatures, whether hot or cold, the tube helps maintain engine temperature within safe limits. Under heavy loads or at varying speeds, it ensures consistent coolant flow, contributing to stable engine operation. Its robust construction and efficient design allow it to withstand the rigors of heavy-duty truck operation, providing reliable cooling system performance in diverse environments.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Water Transfer Tube (Part 3643078) in Cummins Engines

The Water Transfer Tube (part number 3643078) is a critical component in several Cummins engine models, ensuring efficient thermal management and overall engine performance. This part is designed to facilitate the transfer of water between different sections of the engine cooling system, maintaining optimal operating temperatures and preventing overheating.

QSK78 Engine Series

In the QSK78 engine series, the Water Transfer Tube plays a vital role in the engine’s cooling system. This series of engines is known for its robust design and high power output, making it suitable for heavy-duty applications. The Water Transfer Tube ensures that the cooling system operates efficiently, contributing to the engine’s longevity and reliability.

CM500 Engine Series

Similarly, in the CM500 engine series, the Water Transfer Tube is integral to the cooling system. The CM500 engines are designed for commercial and industrial applications, requiring a reliable and efficient cooling system to handle the demands of continuous operation. The Water Transfer Tube helps maintain consistent temperatures, preventing thermal stress and ensuring the engine runs smoothly.

Integration and Functionality

The Water Transfer Tube is engineered to fit seamlessly within the engine’s cooling system architecture. It is designed to withstand the high pressures and temperatures typical of engine environments. The tube’s precise dimensions and material composition ensure it can handle the flow of coolant effectively, minimizing the risk of leaks and maintaining the integrity of the cooling system.

By integrating this component into the engine’s design, Cummins ensures that the cooling system operates at peak efficiency, contributing to the overall performance and durability of the engine.

Role of Part 3643078 Water Transfer Tube in Auxiliary Cooling Systems

The 3643078 Water Transfer Tube is integral to the operation of auxiliary cooling systems in engine setups. This component facilitates the circulation of coolant between the primary engine cooling system and the auxiliary cooling system.

In the auxiliary cooling system, the Water Transfer Tube connects to the engine’s main coolant passages, allowing coolant to flow from the engine to the auxiliary cooler. This setup ensures that the coolant is effectively cooled before it returns to the engine, maintaining optimal operating temperatures.

The tube interfaces with the thermostat housing, enabling regulated coolant flow based on engine temperature. It also connects to the auxiliary cooler, which may include components such as the oil cooler or transmission cooler, depending on the engine’s requirements.

Additionally, the Water Transfer Tube works in conjunction with the water pump, ensuring consistent coolant circulation throughout the system. This integration helps in dissipating heat more efficiently, protecting engine components from overheating.

Overall, the 3643078 Water Transfer Tube plays a significant role in enhancing the performance and reliability of the auxiliary cooling system, contributing to the engine’s overall efficiency and longevity.

Conclusion

The Cummins 3643078 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks and Cummins engines. Its efficient design and robust construction ensure optimal heat management, contributing to the engine’s performance and longevity. Proper installation, regular maintenance, and understanding its role in both primary and auxiliary cooling systems are essential for maximizing the benefits of this part.

SPECIFICATIONS

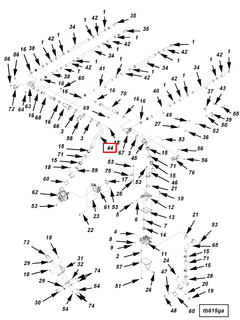

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.