3640343

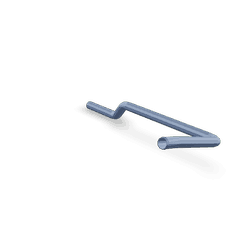

Water Transfer Tube

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3640343 Water Transfer Tube is a component designed for use in heavy-duty trucks. It plays a role in the engine’s cooling system by ensuring efficient operation and longevity of the engine. This part is integral to maintaining the optimal temperature of the engine by facilitating the transfer of coolant between the engine and the radiator 1.

Purpose and Function

The primary role of the Water Transfer Tube in a truck’s cooling system is to enable the movement of coolant. Coolant is circulated from the engine to the radiator where it is cooled, and then returned to the engine. This continuous cycle helps in dissipating the heat generated by the engine, thus maintaining its operating temperature within a safe range. The Water Transfer Tube is a conduit in this cycle, ensuring that coolant flows smoothly and efficiently between these critical components 2.

Key Features

The Cummins 3640343 Water Transfer Tube is constructed from materials that offer durability and resistance to the corrosive effects of coolant. Its design includes precise fittings and connections that ensure a secure and leak-free attachment to the engine and radiator. The tube’s dimensions are engineered to accommodate the flow rate required for effective cooling, and it may feature reinforcements or unique shapes to enhance its performance under the demanding conditions typical of heavy-duty truck operations 3.

Benefits

By ensuring a consistent and efficient flow of coolant, the Water Transfer Tube contributes to improved engine cooling. This results in more stable engine temperatures, which can lead to enhanced engine performance and longevity. The tube’s robust construction and design also add to the reliability of the truck’s cooling system, reducing the likelihood of failures that could lead to engine overheating.

Installation and Compatibility

Proper installation of the Water Transfer Tube is vital for its effective function. It should be securely fitted to prevent leaks and ensure that coolant flows without obstruction. The tube is designed to be compatible with specific Cummins engine models, ensuring that it meets the cooling requirements of these engines. It is also engineered to work within the broader context of the truck’s cooling system, integrating seamlessly with other components.

Maintenance and Troubleshooting

Regular maintenance of the Water Transfer Tube is important to ensure its continued efficient operation. This includes checking for signs of wear, corrosion, or leaks, and addressing any issues promptly. Common problems may include blockages or damage to the tube, which can impede coolant flow. Troubleshooting steps may involve cleaning the tube, repairing any damage, or replacing it if necessary. Periodic inspections are recommended to catch potential issues early and maintain the integrity of the cooling system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industries. The company is committed to producing reliable and efficient engine components, including the Water Transfer Tube, which reflects its dedication to enhancing the performance and durability of heavy-duty trucks.

Role of Part 3640343 Water Transfer Tube in Engine Systems

The 3640343 Water Transfer Tube is integral to the efficient operation of both the main engine system and the auxiliary cooling system.

In the main engine system, this component facilitates the smooth transfer of coolant between the engine block and the heat exchanger. This ensures that the engine maintains optimal operating temperatures, preventing overheating and potential damage to engine components. The Water Transfer Tube works in conjunction with the thermostat and coolant pump to regulate the flow of coolant, adapting to varying engine loads and temperatures.

Within the auxiliary cooling system, the Water Transfer Tube plays a similarly important role. It ensures that ancillary components, such as the turbocharger and aftercooler, receive a consistent supply of coolant. This is particularly important in high-performance or high-stress environments where these components are subject to extreme temperatures. The efficient transfer of coolant helps to prolong the lifespan of these components and maintain overall system reliability.

Overall, the Water Transfer Tube is a key element in maintaining the thermal stability of both the main engine and its auxiliary systems, contributing to the durability and performance of the entire engine assembly.

Conclusion

The Cummins 3640343 Water Transfer Tube is a critical component in the cooling systems of heavy-duty trucks. Its role in facilitating the efficient transfer of coolant ensures that engines maintain optimal operating temperatures, leading to enhanced performance and longevity. Proper installation, maintenance, and understanding of its function are essential for the reliable operation of the cooling system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.