3639362

Water Transfer Tube

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3639362 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the vehicle 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of a truck’s cooling system. Its general function is to ensure that the engine remains at an appropriate operating temperature by circulating coolant from the engine to the radiator and back. This circulation helps dissipate heat generated by the engine, preventing overheating and potential damage 2.

Purpose of the 3639362 Water Transfer Tube

The 3639362 specifically serves to transfer coolant between the engine and the radiator in commercial trucks equipped with Cummins engines. By providing a direct pathway for coolant flow, it plays a role in the cooling system by ensuring that heat is effectively managed and that the engine operates within its designed temperature range 3.

Key Features

The design and construction of the 3639362 incorporate several features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and high temperatures. The tube may feature specific connection types that ensure a secure fit within the cooling system, and its design may include reinforcements or unique attributes to withstand the rigors of commercial truck operation 4.

Benefits of Using the 3639362 Water Transfer Tube

Utilizing the 3639362 offers several advantages. It contributes to improved coolant flow, which can lead to more effective engine cooling. This enhanced coolant circulation can provide better engine protection against overheating, especially under demanding conditions. Additionally, the tube’s durable construction and reliable performance increase the overall reliability of the truck’s cooling system 5.

Installation Considerations

When installing the 3639362, it is important to follow guidelines and best practices to ensure compatibility with the specific truck model and to meet any specific installation requirements. Proper installation is key to achieving the intended performance and longevity of the component within the cooling system 6.

Troubleshooting Common Issues

Common problems associated with Water Transfer Tubes can include leaks or blockages. These issues may arise due to wear, corrosion, or improper installation. Troubleshooting steps may involve inspecting the tube and connections for signs of damage, ensuring that all connections are secure, and checking for any obstructions within the tube that could impede coolant flow 7.

Maintenance Tips

To ensure optimal performance of the 3639362, regular maintenance is recommended. This includes inspecting the tube at regular intervals for any signs of wear or damage, cleaning the tube and its connections to prevent buildup that could affect coolant flow, and considering replacement if significant wear or corrosion is detected 8.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and high-performance components, including the 3639362, which is part of its comprehensive product offering for commercial vehicles 9.

Application in Cummins Engines

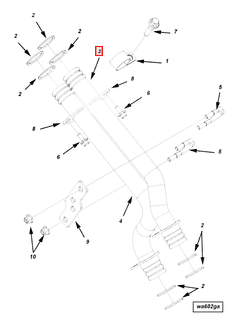

The Water Transfer Tube is integral to the following Cummins engine models:

- QSK78

- CM500

In these engines, the Water Transfer Tube connects the engine’s coolant passages, allowing for the smooth flow of coolant. This ensures that heat generated during combustion is effectively managed, preventing overheating and potential engine damage 10.

Role of Part 3639362 Water Transfer Tube in Engine Systems

The 3639362 is an essential component in the efficient operation of various engine systems, particularly in the context of plumbing, aftercooler water systems, and auxiliary cooling setups.

In the plumbing system, the Water Transfer Tube facilitates the movement of water between different sections of the engine, ensuring that all components receive the necessary cooling. This is particularly important in high-stress areas where overheating can lead to reduced efficiency and potential damage 11.

Within the aftercooler water system, the tube plays a significant role in maintaining the optimal temperature of the air-fuel mixture post-compression. By efficiently transferring water, it helps in cooling the compressed air, which in turn enhances the combustion process and overall engine performance 12.

In the auxiliary cooling system, the Water Transfer Tube is integral to distributing coolant to areas that require additional cooling beyond the primary system. This ensures that all engine components, especially those under high thermal stress, are adequately cooled, thereby prolonging the engine’s lifespan and maintaining its efficiency 13.

Conclusion

The 3639362 Water Transfer Tube is a key element in ensuring the smooth and efficient operation of interconnected engine systems. Its role in maintaining optimal engine temperature is crucial for the performance and longevity of commercial trucks equipped with Cummins engines. Regular maintenance and proper installation are essential to maximize the benefits of this component.

-

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

QSK23 CM2350 K127, Service Manual (5504160)

↩ -

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

QSK23 CM2350 K127, Service Manual (5504160)

↩ -

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

QSK23 CM2350 K127, Service Manual (5504160)

↩ -

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.