This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

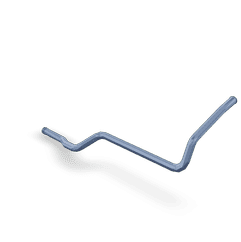

The Cummins 3637132 Water Transfer Tube is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s cooling system, contributing to the overall efficiency and reliability of the engine. Understanding its purpose and operation is key to maintaining the performance of commercial trucks.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit within the cooling system of an engine. Its function is to facilitate the movement of coolant between various components, such as the engine block and the radiator. This movement is vital for dissipating heat generated by the engine, thereby maintaining optimal operating temperatures and preventing overheating 1.

Purpose of the Cummins 3637132 Water Transfer Tube

This Cummins part plays a role in the truck’s cooling system by enabling the circulation of coolant. It connects the engine to the radiator, allowing coolant to absorb heat from the engine and transfer it to the radiator, where it is dissipated into the atmosphere. This process is fundamental to the engine’s thermal management 2.

Key Features

The Cummins 3637132 Water Transfer Tube is constructed from materials that offer durability and resistance to the corrosive effects of coolant. Its design includes features that enhance the efficiency of coolant flow, such as smooth internal surfaces and precise fittings. These attributes contribute to the tube’s longevity and reliable performance within the cooling system.

Benefits of Using the Cummins 3637132 Water Transfer Tube

Incorporating this part into a truck’s cooling system can lead to improved coolant flow, which in turn supports better engine temperature regulation. This can result in enhanced engine protection against overheating and increased reliability of the cooling system as a whole.

Installation Considerations

When installing the Cummins 3637132 Water Transfer Tube, it is important to follow manufacturer guidelines to ensure proper fit and function. Preparatory steps may include cleaning the installation area and inspecting the tube for any damage. The use of appropriate tools and adherence to best practices during installation will help to maintain the tube’s performance and integrity.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3637132 Water Transfer Tube is important to ensure its continued efficient operation. This includes checking for leaks, inspecting the condition of the tube, and ensuring that all connections are secure. Common issues may include blockages or corrosion, which can be addressed through cleaning or replacement as necessary.

Compatibility and Application

The Cummins 3637132 Water Transfer Tube is designed for specific applications within the commercial truck industry. It is important to verify compatibility with the truck’s make and model to ensure proper function and integration within the cooling system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability in the commercial truck industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all of which are designed to meet the demanding requirements of commercial transportation.

Water Transfer Tube (Part 3637132) in Cummins Engines

The Water Transfer Tube (part 3637132) is a critical component in the cooling systems of various Cummins engines, including the QSK60 and CM500 series. This part is integral to maintaining optimal engine performance by ensuring efficient heat transfer and preventing overheating.

QSK60 Series

In the QSK60 engines, the Water Transfer Tube is designed to facilitate the movement of coolant between different parts of the engine. This is particularly important in high-performance applications where the engine operates under significant stress, necessitating effective thermal management. The tube connects the engine’s water jackets to the radiator, ensuring that heat is effectively dissipated.

CM500 Series

Similarly, in the CM500 engines, the Water Transfer Tube plays a vital role in the engine’s cooling system. The CM500 series is known for its robust design and reliability, often used in heavy-duty applications. The water transfer tube in these engines is engineered to withstand high pressures and temperatures, ensuring that the engine remains within safe operating limits.

Common Functionality

Across both the QSK60 and CM500 series, the Water Transfer Tube is designed to be durable and resistant to corrosion, which is crucial for maintaining the integrity of the cooling system over time. This part is typically made from high-quality materials that can endure the harsh conditions within the engine compartment.

The installation of the Water Transfer Tube is a precise process, requiring careful alignment and secure fitting to ensure that there are no leaks or inefficiencies in the cooling system. Proper installation is essential for the longevity and performance of the engine.

Role of Part 3637132 Water Transfer Tube in Engine Systems

The part 3637132 Water Transfer Tube is an essential component in the efficient operation of various engine systems, particularly those involving cooling and aftercooling processes. This tube facilitates the movement of water between different components, ensuring optimal performance and longevity of the engine.

Plumbing Integration

In the engine’s plumbing system, the Water Transfer Tube connects critical components such as the radiator, water pump, and thermostat housing. It ensures a consistent flow of coolant, which is vital for maintaining the engine’s operating temperature. The tube’s design allows for efficient water circulation, reducing the risk of overheating and potential engine damage.

Aftercooler Water System

For engines equipped with an aftercooler, the Water Transfer Tube plays a significant role in the aftercooling process. The aftercooler uses water to cool the compressed air from the turbocharger before it enters the engine’s combustion chambers. The tube ensures a steady supply of water to the aftercooler, enhancing the efficiency of the cooling process and improving overall engine performance.

By maintaining a consistent water flow, the tube helps in reducing the temperature of the intake air, which in turn increases the air density. This results in better combustion efficiency and increased power output. Additionally, the cooled air reduces the risk of detonation, contributing to the engine’s reliability and durability.

Overall Functionality

The Water Transfer Tube is integral to the engine’s cooling and aftercooling systems. Its role in facilitating the movement of water between components ensures that the engine operates within safe temperature ranges, enhancing performance and reliability. The tube’s efficient design and robust construction make it a key component in maintaining the engine’s overall health and efficiency.

Conclusion

The Cummins 3637132 Water Transfer Tube is a vital component in the cooling systems of commercial trucks, particularly those equipped with Cummins engines. Its role in facilitating efficient coolant flow ensures optimal engine temperature regulation, preventing overheating and enhancing engine reliability. Proper installation, regular maintenance, and understanding its function within the engine’s cooling and aftercooling systems are essential for maximizing the performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.