This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

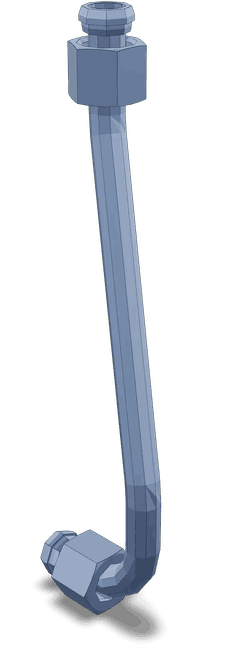

The Cummins 3635317 Water Drain Tube is a critical component in commercial truck engines, designed to manage water accumulation within the engine compartment. Effective water management is essential for preventing damage and ensuring optimal engine performance 1.

Basic Concepts of Water Drain Tubes

Water drain tubes are components that facilitate the removal of water from an engine system. They provide a pathway for water, such as condensation or coolant leaks, to exit the engine compartment, maintaining a dry environment crucial for the longevity and performance of engine components 2. These tubes are typically made from durable materials like rubber, plastic, or metal, chosen for their resistance to corrosion and ability to withstand high temperatures.

Purpose of the Cummins 3635317 Water Drain Tube

The Cummins 3635317 Water Drain Tube is designed to remove condensation and other water accumulations from the engine compartment. By providing a dedicated channel for water to exit, it prevents water from pooling in areas where it could cause damage or reduce efficiency. This part helps maintain a dry environment within the engine, preventing rust and corrosion on metal components 3.

Key Features

The Cummins 3635317 Water Drain Tube is constructed from materials that resist the harsh conditions within an engine compartment, including high temperatures and exposure to chemicals. It is engineered to fit securely within the engine system, effectively channeling water away from sensitive components. The tube is designed for easy installation and maintenance, contributing to its overall effectiveness.

Benefits of Using the Cummins 3635317 Water Drain Tube

Incorporating the Cummins 3635317 Water Drain Tube into a truck’s engine system offers several advantages. It contributes to improved engine longevity by preventing rust and corrosion. Enhanced performance is another benefit, as a dry engine compartment operates more efficiently. Additionally, the use of this part can lead to reduced maintenance requirements, minimizing the potential for water-related damage to engine components.

Installation and Integration

Proper installation of the Cummins 3635317 Water Drain Tube is crucial for its effective operation. It should be positioned according to the manufacturer’s guidelines to ensure it integrates seamlessly with other engine components. Correct placement and connection are vital to facilitate the efficient drainage of water from the engine compartment. This part is designed to work in conjunction with other elements of the engine system, contributing to overall vehicle efficiency and reliability.

Troubleshooting and Maintenance

Common issues with water drain tubes may include blockages or detachment from the engine system. Regular inspection and cleaning can help prevent these problems and ensure the tube remains effective. Maintenance tips include checking for signs of wear or damage, ensuring it is securely connected, and clearing any obstructions that may impede water flow. Adhering to a maintenance schedule can contribute to the longevity and effectiveness of the Cummins 3635317 Water Drain Tube.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine components. The company has a history of developing reliable and efficient parts that contribute to the performance and durability of commercial vehicles. Cummins’ reputation is built on its dedication to advancing engine technology and providing solutions that meet the demanding requirements of the trucking industry 4.

Role of Part 3635317 Water Drain Tube in Engine Systems

The 3635317 Water Drain Tube is a critical component in managing the fluid dynamics within various engine systems. Its primary function is to facilitate the efficient removal of excess water, thereby maintaining optimal performance and longevity of the engine components.

Integration with Plumbing Systems

In the context of engine plumbing, the Water Drain Tube is strategically positioned to collect and direct water away from sensitive areas. This is particularly important in systems where condensation can accumulate, such as in the intercooler or aftercooler sections. By ensuring that water is promptly drained, the tube helps prevent corrosion and maintains the integrity of the plumbing network.

Interaction with Turbocharger Coolant Systems

When integrated into turbocharger coolant systems, the Water Drain Tube plays a significant role in preserving the efficiency of the turbocharger. Turbochargers operate under extreme conditions, generating considerable heat. The coolant system is designed to manage this heat, but it can also lead to the formation of condensate within the system. The Water Drain Tube ensures that any accumulated water is efficiently removed, preventing dilution of the coolant and ensuring that the thermal management system operates within specified parameters. This, in turn, helps maintain the turbocharger’s performance and extends its service life.

By effectively managing water within these systems, the Water Drain Tube contributes to the overall reliability and efficiency of the engine, underscoring its importance in both plumbing and turbocharger coolant applications.

Conclusion

The Cummins 3635317 Water Drain Tube is an essential component for maintaining the efficiency and reliability of commercial truck engines. Its role in managing water accumulation within the engine compartment is crucial for preventing damage, ensuring optimal performance, and extending the longevity of engine components. Proper installation, regular maintenance, and understanding its integration within engine systems are key to maximizing the benefits of this part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5660005, QSK60G CM2358 K156G.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.