3631934

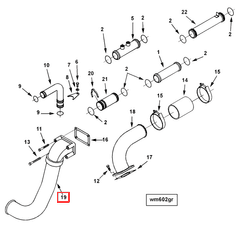

Water Bypass Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Bypass Connector, part number 3631934, manufactured by Cummins, is a critical component in the operation of commercial trucks. Cummins, a renowned name in the commercial truck industry, is known for its high-quality engine components. This part plays a role in the engine cooling system by ensuring optimal coolant flow, which is vital for maintaining engine temperature within safe operating limits 1.

Function and Operation

This Cummins part operates within the engine cooling system by regulating the flow of coolant. It is designed to redirect coolant flow when the thermostat is closed, ensuring that coolant circulates through the engine block and cylinder head. This process helps in maintaining a consistent engine temperature, which is essential for the efficient operation of the engine 2.

Purpose of the Water Bypass Connector

The specific role of this part in the engine cooling system is to enhance the efficiency of coolant circulation. By ensuring that coolant flows through critical engine components even when the thermostat is closed, it contributes to stable engine temperatures. This stability is beneficial for engine performance and longevity, as it prevents overheating and reduces thermal stress on engine components 3.

Key Features

The Water Bypass Connector is characterized by its robust design and the materials used in its construction. It is made from durable materials that can withstand the high temperatures and pressures within the engine cooling system. Its design ensures efficient coolant flow and is tailored to fit seamlessly within the engine’s cooling system architecture 4.

Benefits

The advantages provided by this part include improved engine efficiency through consistent coolant flow, reduced wear and tear on engine components due to stable operating temperatures, and enhanced overall performance of the cooling system. These benefits contribute to the longevity and reliability of the engine.

Installation Process

Proper installation of the Water Bypass Connector involves several steps to ensure optimal performance. It is important to follow manufacturer guidelines for installation, which may include specific torque settings for fasteners and ensuring that all connections are secure and leak-free. Attention to detail during installation is essential for the component’s effective operation.

Common Issues and Troubleshooting

Typical problems associated with the Water Bypass Connector may include leaks, blockages, or failure due to wear and tear. Troubleshooting steps may involve inspecting the connector for signs of damage, ensuring all connections are secure, and checking for proper coolant flow. Regular maintenance can help prevent these issues and ensure the component’s reliable operation.

Maintenance Recommendations

Regular maintenance of the Water Bypass Connector includes periodic inspection for signs of wear or damage, cleaning to remove any debris that may obstruct coolant flow, and replacement according to manufacturer guidelines or when signs of failure are detected. Adhering to these maintenance practices can prevent failures and ensure consistent performance.

Compatibility and Applications

The Water Bypass Connector is designed for use with specific types of engines and truck models. Compatibility information, including any specific application notes or considerations, should be consulted to ensure the component is suitable for the intended application.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of producing reliable and high-quality engine components. The company’s product range includes a variety of engine parts and systems, and its reputation for quality and reliability underscores the trustworthiness of the Water Bypass Connector.

Water Bypass Connector Compatibility with Cummins Engines

This part is a critical component in the cooling system of certain Cummins engines. It is designed to facilitate the recirculation of coolant, ensuring efficient thermal management and preventing overheating.

K38 Series Engines

The K38 series engines, which include the K38-C1000, K38-C1200, and K38-C1500, are among the engines that utilize the Water Bypass Connector. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction equipment and agricultural machinery.

The Water Bypass Connector in these engines is engineered to fit seamlessly into the engine’s cooling system. It connects the coolant bypass line to the engine block, allowing for the controlled flow of coolant. This design ensures that the engine maintains optimal operating temperatures, enhancing longevity and performance.

Grouping of Engines

The K38 series engines are part of a broader family of Cummins engines that share similar design principles and components. The Water Bypass Connector’s compatibility with these engines underscores the importance of standardized parts in maintaining engine efficiency and reliability.

By ensuring that the Water Bypass Connector fits perfectly with the K38 series engines, Cummins maintains a high level of quality and consistency across its engine lineup. This compatibility is crucial for technicians and maintenance professionals who rely on interchangeable parts to perform repairs and maintenance efficiently.

Conclusion

The Water Bypass Connector, part number 3631934, is an essential component in the fluid dynamics of engine systems. Its primary function is to regulate the flow of coolant within the engine, ensuring optimal thermal management. When integrated into the engine system, this part interfaces directly with the manifold, allowing for the controlled diversion of coolant flow, which is particularly important during varying engine operating conditions. Additionally, it is connected to the water tube, a conduit that facilitates the movement of coolant between different sections of the engine. This connection is vital for the efficient circulation of coolant, ensuring that all engine components receive adequate cooling. The Water Bypass Connector’s role in this setup is to manage the coolant flow, preventing overheating and ensuring the engine operates within its optimal temperature range. In summary, this part plays a significant role in the engine’s cooling system by interfacing with the manifold and water tube. Its function is to regulate and optimize coolant flow, contributing to the overall efficiency and reliability of the engine system.

-

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.