This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

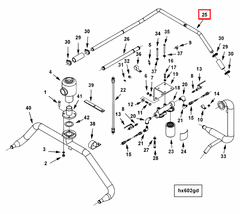

The Cummins 3631330 Water Transfer Tube is a vital component in the cooling systems of commercial trucks. It facilitates the transfer of coolant between the engine and the radiator, ensuring optimal engine temperature and contributing to the efficiency and reliability of the engine cooling system 1.

Function and Operation

The Water Transfer Tube operates within the truck’s cooling system by providing a conduit for coolant to flow between the engine and the radiator. This transfer is essential for dissipating heat generated by the engine, ensuring that the engine operates within its designed temperature range. The tube is positioned to connect key components of the cooling system, allowing for a continuous circulation of coolant that absorbs heat from the engine and releases it into the radiator, where it is cooled by air passing through the radiator fins 2.

Key Features

The Water Transfer Tube is constructed with specific design and material features to enhance its performance. It is made from durable materials that can withstand the high temperatures and pressures within the cooling system. The tube’s dimensions are engineered to ensure a proper fit and efficient coolant flow. Additionally, the design may include features such as reinforced connections to prevent leaks and ensure a secure attachment to the engine and radiator 3.

Benefits

The Water Transfer Tube offers several advantages. It provides improved coolant flow, which contributes to more effective engine cooling. This can lead to enhanced engine performance and longevity. The tube’s durable construction ensures it can withstand the rigors of commercial truck operation, offering reliability in demanding conditions. Furthermore, its efficient design helps maintain engine temperature, which can contribute to fuel efficiency and reduced emissions 4.

Installation and Maintenance

Proper installation of the Water Transfer Tube is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper coolant flow. Regular maintenance checks are recommended to inspect the tube for signs of wear, corrosion, or leaks. Maintenance procedures may include flushing the cooling system, checking connection points for tightness, and replacing the tube if any damage is detected 5.

Troubleshooting

Common problems with Water Transfer Tubes can include leaks, blockages, or damage from corrosion. Diagnostic procedures for identifying issues may involve visual inspections, pressure tests, or coolant flow analysis. Recommended solutions for resolving malfunctions or leaks can range from tightening connections to replacing the tube if it is damaged beyond repair 6.

Manufacturer Overview

Cummins Inc. is a well-established company with a history of producing high-quality components for commercial vehicles. The company has built a reputation in the automotive industry for its commitment to innovation, quality, and customer satisfaction. Cummins’ products are designed to meet the demanding requirements of commercial truck applications, ensuring reliability and performance in various operating environments 7.

Conclusion

The Cummins 3631330 Water Transfer Tube is a critical component in the cooling systems of commercial trucks. Its role in facilitating efficient coolant flow and maintaining optimal engine temperature is essential for the performance and longevity of the engine. Proper installation, regular maintenance, and timely troubleshooting are key to ensuring the reliability and efficiency of this Cummins part.

-

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK60 CM2350 K135. Bulletin Number 5504625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK60 CM2350 K135. Bulletin Number 5504625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK60 CM2350 K135. Bulletin Number 5504625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK60 CM2350 K135. Bulletin Number 5504625.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.