This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

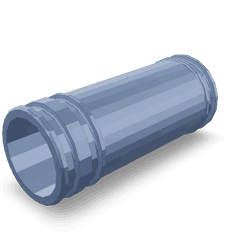

The Cummins 3630436 Water Transfer Tube is a component designed for use in commercial trucks. It facilitates the movement of coolant within the engine’s cooling system, ensuring that the engine operates within optimal temperature ranges. This part is integral to the overall efficiency and reliability of the truck’s engine.

Basic Concepts and Functionality

Water transfer tubes operate on the principle of fluid dynamics, channeling coolant from the engine block to the radiator and back. This circulation helps dissipate heat generated by the engine, maintaining a stable operating temperature. The 3630436 is engineered to enhance this process, ensuring efficient heat transfer and consistent coolant flow 1.

Purpose and Role

The Cummins 3630436 Water Transfer Tube serves to maintain optimal engine temperature and performance. By ensuring a steady flow of coolant, it helps prevent overheating, which can lead to engine damage. This component plays a role in the engine cooling system by facilitating the transfer of heat away from critical engine components, thereby supporting engine longevity and operational efficiency 2.

Key Features

The Cummins 3630436 Water Transfer Tube is characterized by its robust design and high-quality materials. It is constructed to withstand the pressures and temperatures inherent in a truck’s cooling system. Unique features include precision-machined fittings for secure connections and a durable coating that resists corrosion and wear, enhancing its performance and durability 3.

Benefits

Utilizing the Cummins 3630436 Water Transfer Tube offers several advantages. It contributes to improved engine efficiency by ensuring consistent coolant flow, which aids in maintaining optimal engine temperature. This can lead to reduced risk of overheating and enhanced longevity of engine components. Additionally, the tube’s design and materials contribute to its reliability and durability under demanding conditions 4.

Installation and Compatibility

Proper installation of the Cummins 3630436 Water Transfer Tube involves securing it within the engine’s cooling system, ensuring all connections are tight and leak-free. Compatibility with various truck models and engine types is a consideration, with specific guidelines provided by Cummins for optimal performance and integration.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3630436 Water Transfer Tube includes regular inspections for signs of wear or damage, such as cracks or leaks. Cleaning the tube and its connections can prevent blockages and ensure efficient coolant flow. Troubleshooting common issues, such as leaks or reduced coolant flow, may involve checking connections, inspecting for damage, and ensuring the tube is properly installed.

Performance Optimization

To maximize the performance and efficiency of the Cummins 3630436 Water Transfer Tube, it is important to operate the engine under recommended conditions and use appropriate coolant types. Adhering to maintenance schedules and promptly addressing any signs of wear or damage can help ensure the tube continues to function effectively, supporting engine efficiency and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient automotive components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position in the automotive industry.

Role of Part 3630436 Water Transfer Tube in Engine Systems

The 3630436 Water Transfer Tube is integral to the efficient operation of engine systems, particularly in the context of the manifold and water circulation.

In the engine system, the manifold serves as a distribution point for the air-fuel mixture that is directed into the combustion chambers. Proper cooling of the manifold is essential to maintain optimal performance and prevent overheating. This is where the water transfer tube comes into play.

The water transfer tube facilitates the movement of coolant from the engine’s cooling system to the manifold. By ensuring a consistent flow of coolant, it helps in maintaining the manifold at an appropriate temperature. This not only enhances the efficiency of the air-fuel mixture distribution but also contributes to the overall stability and longevity of the engine components.

Additionally, the water transfer tube plays a role in the broader water circulation system of the engine. It ensures that coolant is effectively routed to areas that require cooling, thus supporting the engine’s thermal management. This systematic approach to cooling helps in reducing thermal stress on engine parts, leading to improved performance and reliability.

Conclusion

In summary, the Cummins 3630436 Water Transfer Tube is a key component in the engine’s cooling infrastructure, working in tandem with the manifold and the water circulation system to uphold engine efficiency and durability.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.