This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Inlet Connection 3422812 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the operation of commercial trucks, specifically within the engine’s cooling system. Cummins, known for its robust and reliable engine components, designs the 3422812 to ensure efficient coolant flow, contributing to the overall performance and longevity of the truck’s engine .

Basic Concepts of Water Inlet Connection

A water inlet connection is a component that facilitates the entry of coolant into the engine’s cooling system. Its primary function is to ensure a steady and regulated flow of coolant to the engine, which is vital for maintaining optimal operating temperatures. In the context of a truck’s engine, the water inlet connection operates by allowing coolant to enter the system at a specific point, typically near the thermostat housing, ensuring that the coolant circulates effectively through the engine block and cylinder head .

Purpose of the 3422812 Water Inlet Connection

The 3422812 Water Inlet Connection plays a role in the truck’s cooling system by providing a secure and efficient pathway for coolant to enter the engine. This component is designed to facilitate the flow of coolant from the radiator to the engine, ensuring that the engine remains at an optimal temperature under various operating conditions. By maintaining the correct coolant flow, the 3422812 helps prevent engine overheating, which can lead to decreased performance and potential damage .

Key Features

The 3422812 Water Inlet Connection is constructed from durable materials, ensuring it can withstand the high pressures and temperatures within the engine cooling system. Key features include a precision-machined design that ensures a tight seal, reducing the risk of leaks. Additionally, the connection is designed to be compatible with a variety of truck models and engine types, providing versatility and ease of use. Unique attributes such as integrated gaskets or O-rings enhance its functionality by simplifying the installation process and ensuring a secure fit .

Benefits

The advantages provided by the 3422812 Water Inlet Connection include improved engine performance and reliability. By ensuring a consistent flow of coolant, this component helps maintain optimal engine temperatures, which can lead to enhanced efficiency and reduced wear on engine components. The robust construction and precise design of the 3422812 also contribute to its longevity, making it a reliable choice for commercial truck applications .

Installation Process

Proper installation of the 3422812 Water Inlet Connection involves several steps. Begin by ensuring the engine is cool and the cooling system is drained. Remove the old water inlet connection, taking care to note the position of any gaskets or seals. Clean the mating surface thoroughly to ensure a good seal. Install the new 3422812 Water Inlet Connection, ensuring it is properly aligned and secured. Reassemble the cooling system, refill with coolant, and check for leaks. Tools required may include a socket set, gasket scraper, and torque wrench .

Common Issues and Troubleshooting

Common problems associated with the 3422812 Water Inlet Connection include leaks and blockages. Leaks may occur due to improper installation, damaged gaskets, or corrosion. To address leaks, ensure the connection is properly installed and consider replacing any damaged gaskets. Blockages can be caused by debris or sediment within the cooling system. Regular flushing of the cooling system can help prevent blockages. If issues persist, a thorough inspection of the cooling system may be necessary to identify and resolve the problem .

Maintenance Tips

To ensure the longevity and optimal performance of the 3422812 Water Inlet Connection, regular maintenance practices are recommended. These include periodic inspection for signs of wear or damage, ensuring all connections are secure, and maintaining the cooling system’s cleanliness by regularly flushing and replacing coolant as needed. Additionally, monitoring the engine’s temperature can help identify potential issues early, allowing for timely maintenance or repairs .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial applications, ensuring efficiency, durability, and performance .

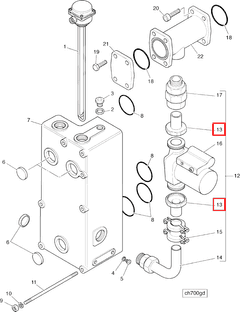

Role of Part 3422812 Water Inlet Connection in Engine Systems

The 3422812 Water Inlet Connection is integral to the efficient operation of various engine systems, particularly those involving coolant circulation and preheating mechanisms.

In the Coolant Heater Starting Aid system, the Water Inlet Connection ensures a steady flow of coolant into the assembly, facilitating effective heat transfer to the engine components. This aids in reducing the viscosity of the oil and other fluids, allowing for smoother engine startup in colder conditions.

When integrated with the Coolant Heater Assembly, the Water Inlet Connection plays a part in maintaining consistent coolant temperature. This is essential for the optimal performance of the heater, which in turn ensures that the engine reaches its operating temperature more quickly.

In the Engine Assembly Heater setup, the Water Inlet Connection contributes to the uniform distribution of heated coolant throughout the engine block. This helps in minimizing thermal stress and enhancing the longevity of engine components.

The Housing of the preheater assembly relies on the Water Inlet Connection to introduce coolant into the system. Proper coolant flow is necessary for the housing to effectively transfer heat to the engine, ensuring that all parts are uniformly warmed before operation.

For the Preheating Assembly, the Water Inlet Connection is vital for initiating the preheating process. It allows coolant to enter the system, where it is heated and circulated to warm the engine components ahead of startup.

In the context of the Water Assembly Pump and Water Pump systems, the Water Inlet Connection ensures that the pump receives a continuous supply of coolant. This is fundamental for the pump’s ability to circulate coolant throughout the engine, maintaining optimal temperature and preventing overheating.

Overall, the Water Inlet Connection is a key component in ensuring that coolant-based systems operate efficiently, contributing to the overall performance and reliability of the engine .

Conclusion

The 3422812 Water Inlet Connection is a critical component in the cooling systems of commercial trucks, ensuring efficient coolant flow and maintaining optimal engine temperatures. Its robust construction, precise design, and compatibility with various engine models make it a reliable choice for enhancing engine performance and longevity. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

: Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

: Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023

: How to Rebuild Any Automotive Engine, Barry Kluczyk, CarTech, 2008

: Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.