The Cummins 3394076 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the vehicle 2.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to flow between the engine and the radiator. Its function is to ensure that the engine remains at a stable temperature by circulating coolant, which absorbs heat from the engine and dissipates it through the radiator 3.

Purpose of the 3394076 Water Transfer Tube

The 3394076 Water Transfer Tube specifically serves to enhance the transfer of coolant between the engine and radiator in commercial trucks. By providing a direct and efficient pathway for coolant flow, it helps maintain consistent engine temperature, which is crucial for engine performance and durability 4.

Key Features

The 3394076 Water Transfer Tube is constructed from high-quality materials that offer resistance to corrosion and wear. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand the pressures and temperatures within the cooling system 1.

Benefits

The advantages of the 3394076 Water Transfer Tube include improved coolant flow, which leads to better heat management and engine protection. Its durable construction ensures reliability even under demanding conditions, contributing to the overall efficiency and lifespan of the truck’s engine 2.

Installation and Compatibility

Proper installation of the 3394076 Water Transfer Tube involves following manufacturer guidelines to ensure a secure fit and optimal performance. It is designed to be compatible with specific truck models and engine types, ensuring that it meets the cooling requirements of the vehicle 3.

Maintenance and Troubleshooting

Regular maintenance of the 3394076 Water Transfer Tube involves inspecting for signs of wear or leaks and ensuring that all connections are tight. Common issues may include blockages or corrosion, which can be addressed through cleaning or replacement as necessary 4.

Performance in Various Conditions

The 3394076 Water Transfer Tube is engineered to perform effectively under a range of operating conditions, including extreme temperatures, heavy loads, and long-distance hauls. Its robust design and material composition allow it to maintain coolant flow and engine temperature stability in diverse environments 1.

Comparison with Other Water Transfer Tubes

When compared to similar components from other manufacturers, the 3394076 Water Transfer Tube may offer distinct advantages in terms of design, performance, and durability. These differences can be attributed to variations in material quality, construction techniques, and engineering specifications 2.

Cummins Corporation Overview

Cummins Inc. is a well-established entity in the automotive industry, known for its commitment to innovation and the development of a wide range of products for commercial trucks. The company’s reputation is built on a history of producing reliable and high-performance components, including the 3394076 Water Transfer Tube 3.

Role of Part 3394076 Water Transfer Tube in Engine Systems

The 3394076 Water Transfer Tube is an integral component in the efficient operation of engine systems, particularly in scenarios where water management is essential for performance and cooling. This component is designed to facilitate the transfer of water between various parts of the engine, ensuring optimal functionality and longevity 4.

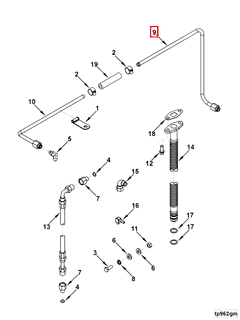

Integration with Plumbing Systems

In engine systems, the plumbing network is responsible for the circulation of fluids, including water, which plays a significant role in cooling and lubrication. The 3394076 Water Transfer Tube is a key element in this network, connecting different sections of the plumbing to ensure a seamless flow of water. Its precise fitting and secure connections are vital for maintaining the integrity of the plumbing system, preventing leaks, and ensuring consistent water pressure throughout the engine 1.

Interaction with Turbocharger Systems

Turbochargers are complex components that rely on efficient cooling to maintain performance and durability. The 3394076 Water Transfer Tube is often utilized in turbocharger systems to manage the flow of water for cooling purposes. By connecting to the turbocharger’s water inlet and outlet, the tube ensures that the turbocharger receives a steady supply of cool water, which is essential for dissipating heat generated during operation. This not only enhances the turbocharger’s efficiency but also extends its operational lifespan by preventing overheating 2.

Turbocharger Plumbing Considerations

When integrating the 3394076 Water Transfer Tube into turbocharger plumbing, it is important to consider the specific requirements of the turbocharger model in use. The tube must be compatible with the plumbing materials and fittings to ensure a secure and leak-free connection. Additionally, the tube’s placement within the plumbing system should be optimized to minimize resistance and turbulence in the water flow, which can affect the overall efficiency of the cooling system 3.

Conclusion

In summary, the 3394076 Water Transfer Tube plays a significant role in the effective management of water within engine systems, particularly in relation to plumbing and turbocharger components. Its proper installation and maintenance are essential for the reliable operation of these systems 4.

-

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ ↩ ↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ ↩ ↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ ↩ ↩ ↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.