This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

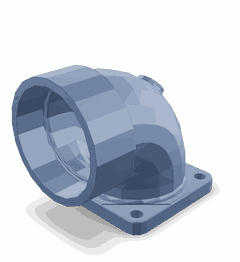

The Water Inlet Connection 3393407 by Cummins is a component designed to facilitate the flow of coolant within the cooling system of heavy-duty trucks. Its purpose is to ensure efficient coolant circulation, which is vital for maintaining optimal engine temperature and performance.

Basic Concepts of Water Inlet Connection

Water inlet connections in engine cooling systems are designed to allow coolant to enter the engine block. They play a role in the cooling system by directing coolant flow to critical areas that require temperature regulation. This ensures that the engine operates within safe temperature ranges, preventing overheating and potential damage 1.

Purpose of the 3393407 Water Inlet Connection

The 3393407 Water Inlet Connection is specifically engineered to enhance the efficiency of coolant flow in a truck’s engine cooling system. It ensures that coolant is distributed evenly throughout the engine, which helps in maintaining consistent temperatures across various engine components. This part contributes to the overall reliability and performance of the engine by supporting effective thermal management 2.

Key Features

The 3393407 Water Inlet Connection boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The design includes precise fittings and connections that facilitate easy installation and secure attachment. Additionally, the part is engineered to withstand high pressures and temperatures commonly encountered in heavy-duty truck engines 3.

Benefits

The advantages of using the 3393407 Water Inlet Connection include improved coolant flow, which enhances the engine’s cooling efficiency. Its durable construction ensures longevity, reducing the need for frequent replacements. The design also allows for straightforward installation, minimizing downtime during maintenance procedures.

Installation Process

Installing the 3393407 Water Inlet Connection involves several steps to ensure proper fitting and function. First, the old connection, if present, should be removed. The mating surfaces should be cleaned to ensure a tight seal. The new connection can then be positioned and secured using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure correct installation.

Common Issues and Troubleshooting

Common problems with water inlet connections may include leaks, corrosion, or blockages. Troubleshooting steps involve inspecting the connection for signs of wear or damage, ensuring all fittings are secure, and checking for proper coolant flow. If issues are detected, the connection may need to be replaced or repaired to restore efficient coolant circulation.

Maintenance Tips

Regular maintenance of the 3393407 Water Inlet Connection is important for ensuring its longevity and efficient operation. This includes periodic inspections for signs of wear or corrosion, ensuring all connections are tight, and verifying that coolant levels are adequate. Following the manufacturer’s maintenance schedule will help prevent issues and ensure optimal performance.

Compatibility and Applications

The 3393407 Water Inlet Connection is designed for use in specific types of engines and truck models. It is important to verify compatibility with the engine and truck make and model to ensure proper fit and function. This part is commonly used in applications where reliable coolant flow is critical for engine performance and durability.

Cummins Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its high-quality engines and components. With a history of innovation and excellence, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation for reliability and performance makes its components, like the 3393407 Water Inlet Connection, a preferred choice for many fleet operators and maintenance professionals.

Cummins Engine Part 3393407: Water Inlet Connection

The Cummins part number 3393407, identified as a Water Inlet Connection, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the flow of coolant into the engine, ensuring efficient thermal management and preventing overheating.

Application in Cummins Engines

QSK50 CM2150 Series

- QSK50 CM2150: This engine benefits from the Water Inlet Connection part 3393407, which is integral to maintaining optimal coolant flow and temperature regulation.

- QSK50 CM2150 MCRS: The MCRS variant also utilizes this part, ensuring that the cooling system operates effectively under various conditions.

QSK60 Series

- QSK60 CM850 MCRS: This high-performance engine incorporates the Water Inlet Connection part 3393407, ensuring that the cooling system can handle the demands of heavy-duty applications.

Other Cummins Engines

- K38: The Water Inlet Connection part 3393407 is also compatible with the K38 engine, providing a reliable method for coolant intake.

- K50: This engine model also relies on the part 3393407 to maintain efficient coolant flow.

- K107: The K107 engine uses this part to ensure that the cooling system functions correctly, contributing to the engine’s overall performance and longevity.

The Water Inlet Connection part 3393407 is a versatile component that plays a crucial role in the cooling systems of these Cummins engines, ensuring that they operate efficiently and reliably across a range of applications.

Understanding the Role of Part 3393407: Water Inlet Connection

The Water Inlet Connection, identified by part number 3393407, serves as a pivotal interface within marine engine systems, facilitating the seamless integration of various components to ensure efficient operation.

Integration with Key Components

Raw Water Inlet and Pump

The Water Inlet Connection is designed to connect directly to the raw water inlet, which is responsible for drawing in external water—typically seawater—into the engine system. This connection ensures a secure and leak-free pathway for the raw water to travel from the inlet to the pump. The pump, in turn, pressurizes the water, enabling it to circulate through the engine’s cooling system.

Seawater and Seawater Pipe Mount

Furthermore, the Water Inlet Connection plays a significant role in linking the seawater pipe mount to the engine. The seawater pipe mount is a structural component that supports the seawater pipe, which transports the raw water from the inlet to various points within the engine where cooling is required. The secure fitting provided by the Water Inlet Connection ensures that the seawater pipe remains firmly in place, minimizing the risk of disconnection or leakage.

Functional Synergy

By effectively connecting these components, the Water Inlet Connection ensures that the raw water pump can efficiently draw in and circulate seawater throughout the engine system. This continuous flow of cool water is essential for maintaining optimal engine temperature, preventing overheating, and ensuring the longevity and reliability of the engine.

Conclusion

In summary, the Water Inlet Connection (part 3393407) is a fundamental component that enables the harmonious operation of the raw water inlet, pump, and seawater pipe mount, contributing to the overall efficiency and performance of marine engine systems.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.