This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

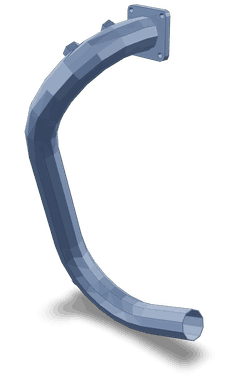

The Water Inlet Connection 3326208 is a component manufactured by Cummins, designed to facilitate the flow of coolant within the cooling system of commercial trucks. This part is integral to maintaining optimal engine temperature, ensuring efficient operation and longevity of the engine. Cummins, a well-established name in the commercial truck industry, is known for producing reliable and high-quality engine components 3.

Basic Concepts of Water Inlet Connection

Water inlet connections in engine cooling systems are designed to allow coolant to enter the engine block. These connections ensure that coolant circulates effectively through the engine, absorbing heat and transferring it away to maintain stable operating temperatures. The design and placement of these connections are critical for efficient coolant flow and engine performance 1.

Purpose of Water Inlet Connection 3326208

The Water Inlet Connection 3326208 serves as the entry point for coolant into the engine block, ensuring that coolant reaches all critical areas that require cooling. This connection interfaces with the thermostat housing and other cooling system components, facilitating seamless coolant circulation 2.

Key Features

The Water Inlet Connection 3326208 is characterized by several key features that enhance its performance. It is constructed from durable materials resistant to corrosion and high temperatures, ensuring longevity. The design includes precise threading and sealing surfaces to prevent leaks. Additionally, it is engineered to accommodate various coolant flow rates, optimizing engine cooling efficiency.

Benefits

The Water Inlet Connection 3326208 offers several advantages. Its design promotes improved coolant flow, which enhances engine cooling efficiency. The durable materials used in its construction contribute to its longevity, reducing the need for frequent replacements. Additionally, the part is designed for ease of installation, minimizing downtime during maintenance procedures.

Installation Process

Installing the Water Inlet Connection 3326208 involves several steps to ensure proper fitting and function. Begin by ensuring the engine is cool and the cooling system is drained. Remove the old connection if replacing, and clean the mating surfaces. Apply a compatible sealant to the threading of the new connection. Carefully thread the new connection into place, ensuring it is snug but not overtightened to avoid damage. Refill the cooling system with the appropriate coolant mixture and check for leaks.

Maintenance Tips

To ensure the longevity and optimal performance of the Water Inlet Connection 3326208, regular maintenance is recommended. Inspect the connection during routine engine checks for signs of wear, corrosion, or leaks. Clean the mating surfaces and threading as needed to prevent debris from affecting the seal. Replace the connection if any damage is detected to maintain efficient coolant flow and engine cooling.

Troubleshooting Common Issues

Common issues with water inlet connections may include leaks, corrosion, and blockages. If a leak is detected, inspect the connection for proper seating and ensure the sealant is applied correctly. Corrosion can be addressed by cleaning the affected areas and applying a corrosion-resistant coating. Blockages may require disassembling the connection to clear any debris, ensuring unobstructed coolant flow.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, ensuring optimal performance and efficiency in various applications 3.

Compatibility with Cummins Engines

-

NH/NT 855: The Water Inlet Connection part 3326208 is compatible with the NH/NT 855 series engines. This part ensures that the coolant is efficiently directed into the engine block, maintaining the necessary temperature levels for optimal engine operation.

-

QSNT14 CM876 N102: This part is also suitable for the QSNT14 CM876 N102 engines. The Water Inlet Connection plays a pivotal role in the cooling system by providing a reliable pathway for coolant to enter the engine, which is essential for preventing overheating and ensuring the engine runs smoothly.

-

N102: The N102 engine series benefits from the use of the part 3326208 as well. This component is integral to the engine’s cooling system, ensuring that coolant is effectively circulated, which is crucial for maintaining engine efficiency and longevity.

Role of Part 3326208 Water Inlet Connection in Engine Systems

The Water Inlet Connection 3326208 is integral to the efficient operation of various engine systems. This component facilitates the entry of coolant into the engine block, ensuring that the cooling system functions optimally.

When coolant flows through the water inlet connection, it enters the engine block where it circulates around the cylinders, pistons, and other critical components. This circulation helps in dissipating heat generated during combustion, thereby maintaining the engine’s operating temperature within safe limits.

The water inlet connection also interfaces with the thermostat, which regulates the flow of coolant based on the engine’s temperature. This ensures that the engine reaches its optimal operating temperature quickly and maintains it consistently.

Additionally, the water inlet connection is often connected to the water pump, which drives the circulation of coolant throughout the engine. This continuous flow is essential for preventing overheating and ensuring the longevity of engine components.

Conclusion

The Water Inlet Connection 3326208 plays a significant role in the thermal management of engine systems by enabling the efficient entry and circulation of coolant. Its durable construction, precise design, and compatibility with various Cummins engines make it a critical component for maintaining optimal engine performance and longevity.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021658.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.