This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

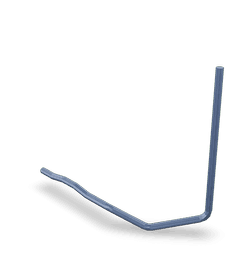

The Cummins 3179850 Water Transfer Tube is designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. It ensures that the engine maintains an optimal operating temperature, which is vital for performance and longevity 3.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the engine’s cooling system that allows coolant to flow from one part of the system to another. Its function is to distribute coolant evenly throughout the engine, which helps in dissipating heat generated during operation 1.

Purpose of the 3179850 Water Transfer Tube

This Cummins part plays a role in the operation of a truck by ensuring that coolant is effectively circulated within the engine. This circulation is important for maintaining the engine’s temperature within a specified range, which enhances the engine’s performance and contributes to the overall efficiency of the cooling system 3.

Key Features

The 3179850 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that are resistant to corrosion and wear, which enhances its durability. The tube’s design includes precise fittings and connections that ensure a secure and leak-free installation 2.

Benefits

The advantages provided by this Cummins part include improved cooling efficiency, which leads to better engine performance. By ensuring that coolant is distributed effectively, the tube reduces the risk of overheating, which can cause engine damage. Furthermore, the enhanced cooling efficiency contributes to the longevity of the engine, as consistent temperature regulation helps prevent wear and tear on engine components 3.

Installation Process

To install the 3179850 Water Transfer Tube, begin by ensuring that the engine is cool and the cooling system is drained. Gather the necessary tools, such as wrenches and sealant, to facilitate the installation process. Follow the manufacturer’s instructions for removing the old tube and installing the new one, taking care to align the fittings correctly and tighten them to the specified torque. After installation, refill the cooling system with the appropriate coolant and check for leaks to ensure a secure fit 1.

Troubleshooting Common Issues

Common problems associated with Water Transfer Tubes include leaks and blockages. To diagnose these issues, inspect the tube and its connections for signs of wear or damage. If a leak is detected, the tube may need to be replaced or repaired. Blockages can be identified by checking the flow of coolant through the system; if there is a restriction, the tube may need to be cleaned or replaced to restore proper coolant circulation 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3179850 Water Transfer Tube, regular maintenance practices should be followed. This includes inspecting the tube and its connections for signs of wear or damage at recommended intervals. Additionally, the cooling system should be flushed periodically to remove any contaminants that could impede coolant flow. Following these maintenance tips will help maintain the efficiency of the cooling system and the performance of the engine 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s product range includes a variety of engines and components that are designed to meet the demanding requirements of commercial applications. The Cummins 3179850 Water Transfer Tube is a testament to the company’s commitment to providing high-quality, reliable components for the trucking industry 1.

Water Transfer Tube (Part 3179850) Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 3179850, is a critical component in the cooling systems of various Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K38 Engine

In the K38 engine, this part plays a pivotal role in the engine’s cooling system. It connects the water pump to the radiator, allowing the coolant to circulate effectively. This tube is engineered to withstand the high pressures and temperatures typical of the K38 engine, ensuring durability and reliability.

K50 Engine

Similarly, in the K50 engine, the Water Transfer Tube is integral to the cooling system. It ensures that the coolant flows smoothly from the water pump to the radiator, maintaining the engine’s temperature within the desired range. The design of this tube for the K50 engine is optimized to handle the specific demands of this engine model, providing a seamless transfer of coolant.

Grouping of Engines

Both the K38 and K50 engines benefit from the Water Transfer Tube in similar ways, as it is a fundamental part of their cooling systems. The tube’s design and material are tailored to meet the specific requirements of each engine, ensuring that it performs optimally in both the K38 and K50 models. This compatibility highlights the versatility and robustness of the Water Transfer Tube in Cummins engines 2.

Role of Part 3179850 Water Transfer Tube in Engine Systems

This Cummins part is an essential component in the efficient operation of various engine systems, particularly those involving aftercooling and water management. This component is integral in the following applications:

Aftercooler Systems

-

Aftercooler Core: The Water Transfer Tube facilitates the movement of coolant through the aftercooler core, ensuring that the compressed air is effectively cooled before it enters the engine’s combustion chamber. This process enhances engine performance and reliability by reducing the temperature of the air, which in turn increases its density and allows for more efficient combustion.

-

Aftercooler Left Bank Return Plumbing: In engines with dual-bank configurations, the tube plays a role in returning cooled water from the left bank of the aftercooler. This ensures balanced cooling across both banks, maintaining optimal engine temperature and performance.

-

Aftercooler Plumbing: The tube is a key element in the overall aftercooler plumbing system, connecting various components to ensure a continuous and efficient flow of coolant. This setup is vital for maintaining the integrity and performance of the aftercooling system.

-

Aftercooler Water Plumbing: Specifically designed for water-based aftercooling systems, the tube ensures that water is properly circulated through the aftercooler, enhancing the cooling process and protecting engine components from overheating.

Engine Components

-

Camshaft and Gear: Although not directly connected, the efficient operation of the Water Transfer Tube contributes to the overall engine cooling, which indirectly supports the longevity and performance of the camshaft and gear system by maintaining optimal operating temperatures.

-

Injectors: Proper engine cooling, facilitated by the Water Transfer Tube, ensures that injectors operate within their specified temperature ranges. This is important for maintaining fuel injection precision and engine performance.

-

Oil Control Valve: Effective engine cooling, supported by the Water Transfer Tube, helps in maintaining the viscosity of the engine oil. This ensures that the oil control valve functions correctly, regulating oil flow and pressure within the engine.

Performance Parts and Plumbing

-

Performance Parts: In high-performance engines, the Water Transfer Tube is often upgraded to handle increased coolant flow demands. This enhancement is crucial for managing the additional heat generated by performance modifications, ensuring that the engine operates efficiently under demanding conditions.

-

Plumbing: The tube is a fundamental part of the engine’s plumbing system, connecting various cooling components and ensuring that coolant is distributed effectively throughout the engine. This is essential for maintaining consistent engine temperatures and performance 3.

Conclusion

The Cummins 3179850 Water Transfer Tube is a vital component in the cooling systems of commercial trucks and various Cummins engines. Its role in ensuring efficient coolant circulation contributes to optimal engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.