This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

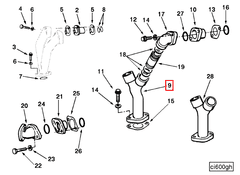

The Water Transfer Connection 3175871, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty trucks. This part is integral to the cooling system, ensuring that the engine operates within optimal temperature ranges, thereby contributing to the overall efficiency and longevity of the vehicle 1.

Basic Concepts of Water Transfer Connection

Water transfer connections in heavy-duty trucks are designed to facilitate the movement of coolant between various components of the engine cooling system. These connections play a role in maintaining consistent coolant flow, which is vital for dissipating heat generated by the engine. Effective coolant circulation helps prevent overheating, which can lead to engine damage and reduced performance. The design and functionality of these connections are crucial for ensuring that the cooling system operates efficiently under a variety of operating conditions 2.

Purpose of the 3175871 Water Transfer Connection

The 3175871 Water Transfer Connection is specifically designed to connect different parts of the engine cooling system, allowing for the seamless transfer of coolant. This part ensures that coolant is distributed evenly throughout the system, which helps maintain consistent engine temperatures. By facilitating proper coolant flow, the 3175871 plays a role in enhancing engine performance and protecting critical components from thermal stress 3.

Key Features

The 3175871 Water Transfer Connection is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and seals that ensure a secure connection, minimizing the risk of leaks. Additionally, the part features smooth internal passages that promote efficient coolant flow, reducing the likelihood of blockages or restrictions. These characteristics contribute to the reliable performance of the cooling system.

Benefits

Incorporating the 3175871 Water Transfer Connection into a truck’s cooling system offers several advantages. It enhances engine efficiency by ensuring consistent coolant flow, which helps maintain optimal operating temperatures. This, in turn, contributes to the reliability and longevity of the engine and cooling system components. The robust construction of the part also ensures durability, reducing the need for frequent replacements and maintenance.

Installation Process

Installing the 3175871 Water Transfer Connection requires careful attention to detail. Begin by ensuring that the engine is cool and the cooling system is drained to prevent spills. Use the appropriate tools to remove the old connection, taking care not to damage surrounding components. Clean the mating surfaces thoroughly before installing the new part. Align the 3175871 with the fittings and secure it in place according to the manufacturer’s instructions. Finally, refill the cooling system with the recommended coolant and check for leaks.

Common Issues and Troubleshooting

Common issues with the 3175871 may include leaks, corrosion, or blockages. To address these problems, first, inspect the connection for signs of wear or damage. If a leak is detected, ensure that the seals are intact and properly seated. Corrosion can be mitigated by using the correct type of coolant and regularly inspecting the part for signs of degradation. Blockages may require disassembling the connection to clear any debris or buildup within the passages.

Maintenance Tips

Regular maintenance of the 3175871 is important for ensuring its optimal performance. Inspect the connection during routine service intervals for signs of wear, corrosion, or leaks. Clean the part as necessary to remove any buildup that could impede coolant flow. Additionally, follow the manufacturer’s recommendations for coolant type and change intervals to prevent issues related to coolant degradation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product offerings are designed to meet the diverse needs of customers, providing solutions that enhance the performance and efficiency of heavy-duty vehicles.

Integration with Engine Components

-

Water Inlet Connection: The Water Transfer Connection interfaces directly with the water inlet connection, allowing for a consistent and regulated flow of coolant into the engine. This ensures that the engine maintains an appropriate operating temperature, preventing overheating and potential damage to sensitive components.

-

Performance Parts: In high-performance engines, the Water Transfer Connection plays a significant role in enhancing the efficiency of performance parts. By ensuring a steady supply of coolant, it helps in maintaining the integrity and performance of parts such as turbochargers, intercoolers, and high-stress bearings.

-

Coolant Circulation System: The connection is a key element in the coolant circulation system, working in tandem with the water pump, radiator, and thermostat. It ensures that coolant is effectively distributed throughout the engine block and cylinder heads, dissipating heat generated during combustion.

-

Thermal Management: Effective thermal management is essential for the reliability and performance of modern engines. The Water Transfer Connection contributes to this by ensuring that coolant reaches all critical areas, including the engine block, cylinder heads, and potentially even the transmission in some systems.

-

Sealing and Integrity: The connection also plays a role in maintaining the sealing integrity of the coolant system. By providing a secure and leak-free passage for coolant, it prevents the loss of coolant and the ingress of contaminants, which could compromise engine performance and lead to corrosion.

Conclusion

The Water Transfer Connection 3175871 is a vital component that ensures the smooth and efficient operation of the engine’s cooling system, directly impacting the performance and durability of various engine parts. Its integration with engine components, role in thermal management, and contribution to the overall efficiency of the cooling system make it an essential part of Cummins’ engine systems.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Thorsten Boger and Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.