This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3170215 Water Transfer Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the transfer of coolant between the engine and the radiator, playing a role in maintaining optimal engine temperature and ensuring efficient operation of the truck’s cooling system.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of a truck’s cooling system. It operates on the principle of fluid dynamics, where coolant is circulated to absorb heat from the engine and dissipate it through the radiator. This process is vital for preventing engine overheating and ensuring consistent performance 1.

Purpose of the 3170215 Water Transfer Tube

The specific role of the 3170215 Water Transfer Tube in a truck’s cooling system is to provide a pathway for coolant to travel from the engine to the radiator and back. This facilitates the removal of excess heat generated by the engine, which is critical for maintaining engine efficiency and longevity.

Key Features

The 3170215 Water Transfer Tube is constructed from durable materials that can withstand the high temperatures and pressures within the cooling system. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance durability and resistance to wear.

Benefits

The use of the 3170215 Water Transfer Tube offers several benefits. It contributes to improved coolant flow, which enhances the efficiency of the engine cooling process. This can lead to more stable engine temperatures and potentially extend the lifespan of the engine by reducing thermal stress 2.

Installation Process

Installing the 3170215 Water Transfer Tube requires careful attention to detail. Preparatory steps include ensuring the engine is cool and the cooling system is drained. The necessary tools for installation may include wrenches and sealant. Following the manufacturer’s instructions for fitting and securing the tube is important to achieve a proper seal and prevent leaks.

Troubleshooting Common Issues

Common issues with Water Transfer Tubes can include leaks or blockages. To troubleshoot these problems, one should inspect the tube and connections for signs of wear or damage. If a leak is detected, the tube may need to be replaced or repaired. Blockages can often be cleared by flushing the cooling system.

Maintenance Tips

Regular maintenance of the 3170215 Water Transfer Tube is important for its longevity and performance. This includes periodic inspections for signs of wear or corrosion, and cleaning the tube as part of routine cooling system maintenance. Adhering to recommended inspection intervals can help prevent unexpected failures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation in power technology.

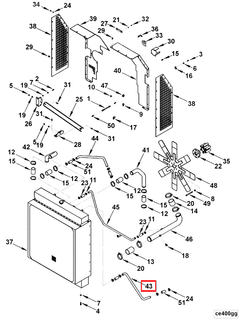

Water Transfer Tube (Part 3170215) in Cummins Engines

The Water Transfer Tube (part 3170215) is a critical component in the cooling system of various Cummins engines, ensuring efficient heat transfer and maintaining optimal operating temperatures. This part is integral to the QSK19 and CM500 engine families, where it facilitates the movement of coolant between different parts of the engine.

QSK19 Engine Family

In the QSK19 engine series, the Water Transfer Tube is designed to connect the engine’s water pump to the radiator, ensuring a continuous flow of coolant. This tube is engineered to withstand high pressures and temperatures, providing a reliable pathway for coolant circulation. The QSK19 engines are known for their robust design and are often used in heavy-duty applications, making the durability and performance of the Water Transfer Tube crucial for maintaining engine efficiency.

CM500 Engine Family

Similarly, in the CM500 engine series, the Water Transfer Tube plays a vital role in the engine’s cooling system. This part ensures that coolant is efficiently transferred from the engine block to the radiator, where it is cooled before being recirculated. The CM500 engines are typically used in marine and industrial applications, where reliable cooling is essential for performance and longevity. The Water Transfer Tube in these engines is designed to handle the unique demands of these environments, providing a seamless connection that supports the engine’s cooling needs.

Integration and Functionality

The Water Transfer Tube is meticulously engineered to fit seamlessly within the engine’s cooling system. It is designed to connect with other components such as the water pump and radiator, ensuring a secure and efficient transfer of coolant. This part is made from high-quality materials that can withstand the harsh conditions within the engine, providing long-lasting performance and reliability.

In both the QSK19 and CM500 engine families, the Water Transfer Tube is a key component that ensures the engine operates within its optimal temperature range. By facilitating the efficient movement of coolant, this part helps to prevent overheating and maintain the engine’s performance over time.

Role of Part 3170215 Water Transfer Tube in Engine Systems

The part 3170215 Water Transfer Tube is an essential component in the engine cooling system, facilitating the efficient movement of coolant between various parts of the engine. This tube ensures that the coolant is distributed evenly, maintaining optimal engine temperature and preventing overheating.

In the engine cooling system, the Water Transfer Tube connects the engine block to the radiator, allowing coolant to flow from the engine to the radiator where it is cooled before returning to the engine. This continuous circulation is vital for dissipating heat generated during engine operation.

Additionally, the Water Transfer Tube plays a role in the thermostat housing system. It ensures that coolant flows to the thermostat, which regulates the flow of coolant based on engine temperature. This regulation helps in achieving the engine’s optimal operating temperature more quickly and maintains it during operation.

The tube also interfaces with the water pump, which drives the circulation of coolant throughout the engine system. Efficient coolant flow is dependent on the proper functioning of the Water Transfer Tube, ensuring that the water pump can effectively move coolant to all necessary engine components.

Furthermore, the Water Transfer Tube is connected to the heater core, allowing coolant to flow through the vehicle’s heating system. This connection ensures that the cabin can be warmed effectively during cold weather, enhancing passenger comfort.

Conclusion

In summary, the part 3170215 Water Transfer Tube is integral to the engine cooling system, ensuring that coolant is efficiently circulated throughout the engine, radiator, thermostat housing, water pump, and heater core. This component helps maintain engine performance and longevity by managing thermal conditions within the engine 3.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Konrad Reif Ed, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems, Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.