This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3093331 Water Inlet Connection is a critical component in the engine cooling systems of commercial trucks. It ensures the efficient flow of coolant into the engine, maintaining optimal operating temperatures. This part is integral to the reliability and performance of the engine cooling system.

Basic Concepts of Water Inlet Connection

Water inlet connections in engine cooling systems are designed to direct coolant from the radiator into the engine block. This process is essential for dissipating heat generated by the engine’s operation. The coolant absorbs heat as it circulates through the engine and then transfers this heat to the radiator, where it is expelled into the atmosphere. The efficient operation of this system is vital for maintaining engine temperature within safe limits 1.

Purpose of the 3093331 Water Inlet Connection

The 3093331 Water Inlet Connection facilitates the entry of coolant into the engine, ensuring consistent coolant flow. It is positioned to distribute coolant evenly throughout the engine block, enhancing the cooling process. This component is crucial for preventing engine overheating and ensuring stable engine performance 2.

Key Features

The 3093331 Water Inlet Connection is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the pressures and temperatures associated with engine operation. The connection features precise fittings that ensure a leak-free seal, contributing to the overall efficiency of the cooling system. Additionally, its design allows for easy installation and maintenance, enhancing its practicality in commercial truck applications 3.

Benefits

The advantages provided by the 3093331 Water Inlet Connection include improved coolant flow, leading to more effective engine cooling. This enhancement in coolant circulation contributes to better engine protection by maintaining optimal operating temperatures. Furthermore, the reliable design of this component increases the overall reliability of the engine cooling system, reducing the likelihood of overheating-related issues 4.

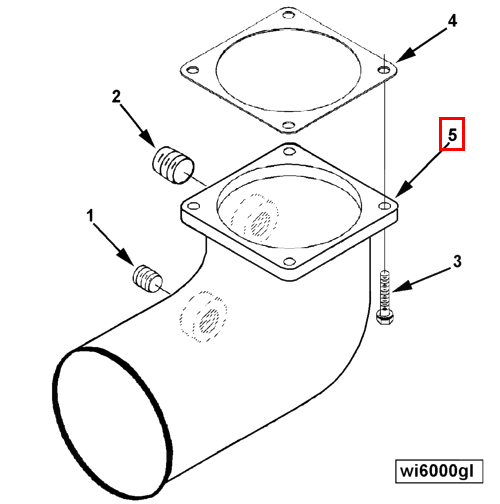

Installation Process

Installing the 3093331 Water Inlet Connection involves several steps to ensure proper fitting and function. Begin by ensuring the engine is cool and the cooling system is drained. Remove the old water inlet connection, if present, and clean the mating surface. Apply a suitable gasket or sealant as per the manufacturer’s recommendations. Position the new water inlet connection and secure it in place using the specified torque settings for the bolts. Finally, refill the cooling system with the appropriate coolant mixture and check for leaks upon initial operation 5.

Common Issues and Troubleshooting

Typical problems associated with water inlet connections may include leaks, blockages, or corrosion. To diagnose these issues, inspect the connection for signs of wear, damage, or leaks. If a leak is detected, ensure the gasket or sealant is correctly applied and the connection is properly tightened. Blockages may require disassembly and cleaning of the connection. Corrosion can be addressed by replacing the affected parts and ensuring the cooling system is properly maintained 6.

Maintenance Tips

Regular maintenance practices for the 3093331 Water Inlet Connection include periodic inspection for signs of wear or damage, ensuring the connection remains leak-free, and verifying that the coolant level and mixture are correct. It is also advisable to follow the manufacturer’s recommendations for coolant replacement intervals to prevent buildup of contaminants that could affect the efficiency of the cooling system 7.

Manufacturer - Cummins

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in engine manufacturing. With a rich history in the industry, Cummins has established a reputation for producing reliable and high-performance engines. The company’s dedication to research and development ensures that its products, including the 3093331 Water Inlet Connection, meet the demanding requirements of commercial truck applications 8.

Water Inlet Connection Part 3093331 Compatibility with Cummins Engines

The Water Inlet Connection part number 3093331, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part plays a role in the engine’s cooling system by providing a secure and efficient connection for water inlet pipes.

QST30 CM2350 T101 and QST30 CM552

For the QST30 CM2350 T101 and QST30 CM552 engines, the Water Inlet Connection part 3093331 is engineered to ensure optimal thermal management. It is specifically designed to fit the unique requirements of these engines, ensuring that the water inlet pipes are securely attached and that the cooling system operates efficiently. This compatibility is important for maintaining the engine’s performance and longevity.

The part’s design takes into account the specific dimensions and tolerances of the QST30 CM2350 T101 and QST30 CM552 engines, ensuring a precise fit and reliable performance. This compatibility allows for easy installation and maintenance, making it a preferred choice for technicians and engineers working with these engine models 9.

Role of Part 3093331 Water Inlet Connection in Engine Systems

The Water Inlet Connection, identified by part number 3093331, is integral to the efficient operation of engine cooling systems. This component facilitates the entry of coolant into the engine block, ensuring that the engine maintains optimal operating temperatures.

Integration with Engine Components

-

Water Pump: The Water Inlet Connection interfaces directly with the water pump, allowing coolant to be drawn from the reservoir and circulated through the engine. This connection ensures a consistent flow of coolant, which is essential for dissipating heat generated by the combustion process.

-

Thermostat Housing: Positioned between the water pump and the thermostat housing, the Water Inlet Connection plays a role in regulating the flow of coolant based on engine temperature. It allows the thermostat to open and close as needed, controlling the circulation of coolant to prevent overheating.

-

Engine Block: Once coolant enters through the Water Inlet Connection, it flows into the engine block, where it absorbs heat from the cylinders and other critical components. This absorbed heat is then carried away from the engine, maintaining a stable operating temperature.

-

Radiator Hoses: The Water Inlet Connection is typically connected to the upper radiator hose, which carries hot coolant from the engine to the radiator for cooling. This setup ensures that the coolant is efficiently cycled through the system, enhancing the overall cooling efficiency.

-

Coolant Reservoir: The connection also links to the coolant reservoir, allowing for the addition or removal of coolant as needed. This helps maintain the proper coolant level and prevents air pockets within the cooling system, which can lead to inefficient heat transfer.

Product Installation Considerations

When installing the Water Inlet Connection, it is important to ensure a secure and leak-free fit. Proper sealing is essential to prevent coolant loss and maintain system pressure. Additionally, the connection should be aligned correctly with other components to ensure unobstructed coolant flow.

Conclusion

The Water Inlet Connection part 3093331 is a key component in the engine’s cooling system, facilitating the smooth and efficient circulation of coolant to maintain engine temperature within safe limits. Its robust design, compatibility with various Cummins engines, and ease of installation make it a reliable choice for commercial truck applications.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩ -

Cummins Inc. (n.d.). X12 CM2670 X135C, Service Manual (5579778).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.