This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

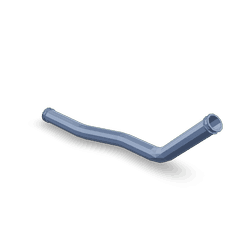

The Cummins 3092909 Water Transfer Tube is a component designed for use in heavy-duty trucks. It facilitates the movement of coolant within the engine’s cooling system, contributing to the maintenance of optimal engine temperature. This part is integral to the efficient operation of the truck, ensuring that the engine remains within safe operating temperatures under various conditions.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit that allows coolant to circulate between different parts of a truck’s cooling system. Its function is to transfer coolant from the engine block to the radiator and back, playing a role in dissipating heat generated by the engine. This circulation helps maintain the engine at a temperature that ensures efficient operation and prevents overheating, which can lead to engine damage 1.

Purpose of the Cummins 3092909 Water Transfer Tube

The Cummins 3092909 Water Transfer Tube is specifically designed to enhance the coolant circulation process in heavy-duty trucks. It connects key components within the cooling system, allowing for efficient transfer of coolant. This ensures that heat is effectively managed, contributing to the engine’s overall performance and longevity.

Key Features

The Cummins 3092909 Water Transfer Tube is constructed from durable materials, ensuring it can withstand the high pressures and temperatures within the engine cooling system. Its design includes precise fittings and connections that facilitate a secure and leak-free installation. Additionally, the tube may feature reinforced sections to handle the rigors of heavy-duty use, enhancing its durability and performance.

Benefits

The use of the Cummins 3092909 Water Transfer Tube offers several advantages. It contributes to improved engine efficiency by ensuring consistent coolant flow, which helps maintain optimal engine temperature. This part also enhances the longevity and reliability of the engine, allowing it to operate efficiently under a wide range of conditions. Its robust construction and design ensure it can withstand the demands of heavy-duty use, providing dependable performance over time 2.

Installation Process

Installing the Cummins 3092909 Water Transfer Tube requires careful attention to detail to ensure a secure and efficient fit. Preparatory steps include ensuring the engine is cool and the cooling system is drained to prevent spills. The necessary tools for installation may include wrenches, sealant, and possibly a torque wrench for tightening connections. Following the manufacturer’s instructions for installation is crucial to ensure the tube is properly positioned and connected, facilitating effective coolant flow.

Troubleshooting Common Issues

Common issues with water transfer tubes can include leaks or blockages, which may arise from improper installation, wear and tear, or debris within the cooling system. To address these problems, it is important to inspect the tube and connections for signs of damage or wear. Cleaning the cooling system and ensuring all connections are tight can help resolve many issues. In cases of significant damage, replacement of the tube may be necessary.

Maintenance Tips

Regular maintenance of the Cummins 3092909 Water Transfer Tube is key to ensuring its longevity and efficient operation. This includes periodic inspections for signs of wear, leaks, or blockages. Cleaning the cooling system as part of regular maintenance can help prevent debris buildup, which may obstruct coolant flow. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures will help maintain the tube’s performance and extend its service life.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly for diesel engines and related components, Cummins is committed to delivering high-quality, reliable products that meet the demanding needs of its customers. The company’s extensive product range and focus on innovation ensure it remains a trusted name in the production of automotive and heavy-duty truck parts 3.

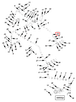

Cummins Water Transfer Tube 3092909 Compatibility

The Cummins Water Transfer Tube part number 3092909 is designed to fit seamlessly within a variety of engine models. This part is crucial for maintaining the proper flow of coolant within the engine, ensuring optimal performance and longevity.

QST30 CM552 Engines

The Water Transfer Tube 3092909 is specifically engineered to integrate with the QST30 CM552 engines. This compatibility ensures that the coolant is efficiently circulated, preventing overheating and maintaining the engine’s operational efficiency. The design of the tube allows for a precise fit, ensuring that there are no leaks or inefficiencies in the coolant system.

Grouping of Engines

While the Water Transfer Tube 3092909 is explicitly mentioned to fit with the QST30 CM552 engines, it is also compatible with other models within the same engine family. This compatibility extends to engines that share similar design and operational parameters, ensuring that the tube can be used across a range of models without modification. This grouping is based on the shared architecture and requirements of the engines, allowing for a standardized part to be used across multiple models.

Role of Part 3092909 Water Transfer Tube in Engine Systems

The part 3092909 Water Transfer Tube is an integral component in the operation of both the primary cooling system and the auxiliary cooling system of an engine.

In the primary cooling system, the Water Transfer Tube facilitates the movement of coolant from the engine block to the radiator. This process is essential for dissipating heat generated by the engine’s operation. The coolant absorbs heat as it circulates through the engine block and cylinder heads. The Water Transfer Tube then directs the heated coolant to the radiator, where it releases the absorbed heat into the atmosphere via the radiator’s fins and fans. This continuous circulation helps maintain optimal engine temperature, preventing overheating and ensuring efficient engine performance.

In the auxiliary cooling system, the Water Transfer Tube plays a similar yet specialized role. This system is designed to provide additional cooling to specific engine components that may experience higher thermal loads, such as turbochargers or aftercoolers. The Water Transfer Tube in this context ensures that coolant is efficiently routed to these components, absorbing excess heat and returning it to the main cooling circuit. This helps in maintaining the integrity and performance of these high-stress components, contributing to the overall reliability and longevity of the engine.

Overall, the Water Transfer Tube is a key element in both cooling systems, ensuring that heat is effectively managed and dissipated, thereby supporting the engine’s operational efficiency and durability.

Conclusion

The Cummins 3092909 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient heat management and engine performance. Its robust design, compatibility with various engine models, and ease of installation make it a reliable choice for maintaining optimal engine temperatures. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.