This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

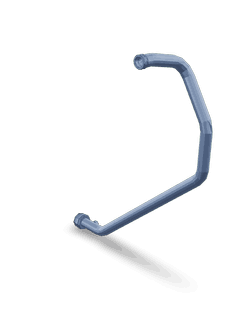

The Cummins 3084385 Water Outlet Tube is a component designed for use in Cummins engines, playing a role in the engine cooling system by facilitating the flow of coolant from the engine to the radiator. This part is significant in maintaining engine performance by ensuring efficient heat dissipation, which is vital for the longevity and reliability of the engine 1.

Basic Concepts of Water Outlet Tubes

Water outlet tubes are integral to the cooling systems of internal combustion engines. They function by directing coolant flow from the engine to the radiator, where the coolant releases heat before returning to the engine. Proper coolant circulation is important for regulating engine temperature, preventing overheating, and ensuring optimal engine operation 2.

Purpose and Role in Truck Operation

In the operation of a truck, the Cummins 3084385 Water Outlet Tube contributes to efficient engine cooling by providing a pathway for coolant to exit the engine and travel to the radiator. This process helps maintain the engine within its optimal temperature range, enhancing performance and reliability. The tube’s role is particularly important in heavy-duty applications where engines operate under high loads and temperatures 3.

Key Features

The Cummins 3084385 Water Outlet Tube is characterized by its durable construction and precise engineering. It is designed to withstand the high pressures and temperatures associated with engine coolant systems. Its compatibility with Cummins engines ensures that it meets the specific requirements for efficient coolant flow and temperature regulation. These features contribute to the tube’s effectiveness and reliability in demanding applications 4.

Benefits

Using the Cummins 3084385 Water Outlet Tube offers several benefits. It enhances engine cooling efficiency by ensuring a smooth and uninterrupted flow of coolant. The tube’s durable construction reduces the risk of coolant leaks, which can lead to engine overheating and damage. Additionally, its precise engineering contributes to better overall engine performance and longevity by maintaining optimal engine temperatures 5.

Troubleshooting and Maintenance

Common issues with water outlet tubes include leaks and blockages. Regular inspection for signs of wear, corrosion, or damage is recommended to prevent these issues. Maintenance procedures may involve cleaning the tube and its connections, ensuring there are no obstructions in the coolant flow path, and replacing the tube if it shows signs of significant wear or damage. Proper maintenance helps ensure the tube continues to function effectively, contributing to engine reliability 6.

Installation Considerations

When installing the Cummins 3084385 Water Outlet Tube, it is important to follow proper torque specifications to ensure connections are secure without overtightening, which could damage the tube or its fittings. Aligning the tube correctly with engine components is also crucial to maintain the integrity of the coolant flow path. Ensuring a secure and leak-free connection is vital to prevent coolant loss and engine overheating 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality and innovation in engine component manufacturing. The company’s expertise and reliability are reflected in the design and performance of the 3084385 Water Outlet Tube 8.

Role of Part 3084385 Water Outlet Tube in Engine Systems

The Part 3084385 Water Outlet Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with aftercoolers. This tube facilitates the movement of water from the aftercooler to other parts of the engine system, ensuring optimal cooling and performance.

Integration with Plumbing

In the context of engine plumbing, the Water Outlet Tube serves as a conduit that directs water flow. It connects to various plumbing components, such as hoses and fittings, to create a seamless water circulation path. This ensures that water is efficiently transported from the aftercooler to other cooling components within the engine system 9.

Function in Aftercooler Water Systems

The aftercooler is a heat exchanger that cools the compressed air from the turbocharger before it enters the engine’s intake manifold. The Water Outlet Tube plays a significant role in this process by allowing cooled water to exit the aftercooler and be recirculated or discharged as needed. This helps maintain the effectiveness of the aftercooler, ensuring that the air entering the engine is at the optimal temperature for combustion efficiency and engine performance 10.

Overall System Contribution

By effectively managing water flow, the Part 3084385 Water Outlet Tube contributes to the stability and reliability of the engine’s cooling system. Its proper function ensures that both the aftercooler and other cooling components operate within their designed parameters, leading to enhanced engine durability and performance 11.

Conclusion

The Cummins 3084385 Water Outlet Tube is a critical component in the engine cooling system, ensuring efficient heat dissipation and maintaining optimal engine performance. Its durable construction, precise engineering, and compatibility with Cummins engines make it a reliable choice for heavy-duty applications. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall reliability and longevity of the engine.

-

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). L9 CM2350 L120C, Service Manual (5504199).

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). L9 CM2350 L120C, Service Manual (5504199).

↩ -

Cummins Inc. (n.d.). L9 CM2350 L120C, Service Manual (5504199).

↩ -

Cummins Inc. (n.d.). L9 CM2350 L120C, Service Manual (5504199).

↩ -

Cummins Inc. (n.d.). L9 CM2350 L120C, Service Manual (5504199).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.