This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

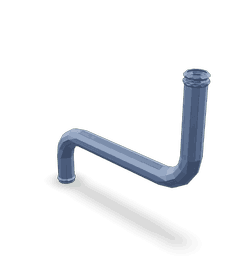

The Cummins 3081689 Water Transfer Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the efficient transfer of coolant within the engine’s cooling system, thereby contributing to the maintenance of optimal engine temperature during operation.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to flow between various components. Its function is to ensure that the coolant circulates effectively, absorbing heat from the engine and dissipating it through the radiator. This process is vital for maintaining engine temperature within safe operating limits, preventing overheating, and ensuring the longevity of engine components 1.

Purpose of the 3081689 Water Transfer Tube

The Cummins 3081689 Water Transfer Tube specifically plays a role in the cooling system by transferring coolant between the engine block and other critical components, such as the radiator or thermostat housing. This transfer is crucial for consistent coolant flow, which helps in evenly distributing the cooling effect across the engine.

Key Features

This Cummins part is constructed from durable materials that can withstand the high temperatures and pressures within the cooling system. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance durability and resistance to wear and tear.

Benefits

The use of the 3081689 Water Transfer Tube offers several benefits. It improves coolant flow efficiency, which contributes to better heat management within the engine. Enhanced coolant circulation leads to improved engine protection against overheating. Furthermore, the reliable performance of the tube increases the overall reliability of the cooling system, reducing the likelihood of engine damage due to overheating 2.

Installation Considerations

Proper installation of the 3081689 Water Transfer Tube involves ensuring that all connections are secure and that the tube is correctly positioned within the cooling system. It may be necessary to use specific tools or follow particular procedures to achieve a proper fit and seal. Attention to detail during installation is important to prevent leaks and ensure optimal performance.

Troubleshooting Common Issues

Common issues with the 3081689 Water Transfer Tube may include leaks or blockages. Leaks can often be identified by coolant loss or visible signs of coolant around the tube’s connections. Blockages may result in reduced coolant flow and can be detected through symptoms such as engine overheating. Troubleshooting steps may involve inspecting connections for tightness, checking for signs of wear or damage, and ensuring that the tube is free from obstructions.

Maintenance Tips

Regular maintenance of the 3081689 Water Transfer Tube is important for its longevity and performance. This includes periodic inspection for signs of wear, corrosion, or damage. Ensuring that connections remain tight and free from leaks is also important. Additionally, following the manufacturer’s recommendations for coolant replacement and system flushing can help maintain the efficiency of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of commercial applications 3.

Conclusion

The Cummins 3081689 Water Transfer Tube is a vital component in the cooling systems of commercial trucks. Its role in facilitating efficient coolant transfer contributes significantly to maintaining optimal engine temperature, preventing overheating, and ensuring the longevity of engine components. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for the effective operation of this part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Gijs Mom. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

John Heywood. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.