This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

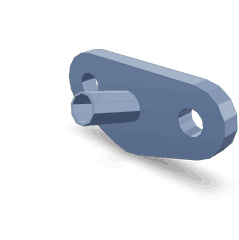

The Water Inlet Connection 3074681, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of commercial vehicles. This part is significant in the context of commercial truck operations as it plays a role in the engine cooling system, contributing to the overall efficiency and longevity of the truck 1.

Basic Concepts of Water Inlet Connection

Water inlet connections in commercial trucks are integral to the engine cooling system. They facilitate the flow of coolant into the engine, which is vital for maintaining optimal operating temperatures. Proper coolant circulation helps prevent engine overheating, which can lead to decreased performance and potential damage. The effectiveness of a water inlet connection can influence the overall performance and reliability of the truck 2.

Purpose of the 3074681 Water Inlet Connection

This part is designed to facilitate the flow of coolant into the engine. It ensures that coolant is delivered efficiently, which aids in regulating engine temperature. By maintaining consistent coolant flow, this component helps to protect the engine from overheating, thereby supporting stable engine performance and longevity 3.

Key Features

The 3074681 Water Inlet Connection is characterized by several notable features. It is constructed from durable materials that can withstand the high temperatures and pressures within the engine cooling system. The connection type is designed to ensure a secure fit, minimizing the risk of leaks. Additionally, the design may include features that enhance coolant flow, contributing to more effective engine temperature regulation.

Benefits

This Cummins part offers several advantages. Improved coolant flow ensures more effective engine cooling, which can enhance engine performance and longevity. The durable construction of the component contributes to its reliability, reducing the likelihood of failures. Additionally, efficient coolant circulation can contribute to overall engine efficiency, potentially leading to better fuel economy and reduced maintenance costs.

Installation Process

Proper installation of this part is important for ensuring optimal performance and longevity. The installation process should begin with ensuring that the engine is cool and the cooling system is drained. The old connection should be removed, and any gaskets or seals should be inspected and replaced if necessary. The new connection should be installed according to the manufacturer’s specifications, ensuring a secure fit. After installation, the cooling system should be refilled and checked for leaks.

Common Issues and Troubleshooting

Frequent problems associated with water inlet connections can include leaks, corrosion, and blockages. Leaks may be caused by improper installation or wear and tear, and can often be addressed by re-securing the connection or replacing damaged components. Corrosion can be mitigated through regular maintenance and the use of appropriate coolants. Blockages may require cleaning or replacement of the connection.

Maintenance Recommendations

Routine maintenance practices are important for upholding the performance and reliability of the 3074681 Water Inlet Connection. Regular inspections should be conducted to check for signs of wear, corrosion, or leaks. Cleaning the connection and surrounding areas can help prevent blockages and ensure efficient coolant flow. Replacement considerations should be based on the condition of the component and manufacturer recommendations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the commercial truck industry for producing high-quality, reliable components. The company’s product offerings include a wide range of engines, powertrains, and related systems designed to meet the demanding requirements of commercial vehicles.

Cummins Part 3074681: Water Inlet Connection

The Cummins part 3074681, identified as a Water Inlet Connection, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the flow of coolant into the engine block, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

Application in Cummins Engines

K19 Series

The K19 engine series, known for its robust performance and reliability, incorporates the Water Inlet Connection part 3074681. This part is integral to the engine’s cooling system, providing a secure and leak-proof connection for the coolant inlet. The design ensures that the coolant flows smoothly into the engine block, enhancing the overall efficiency of the cooling process.

Other Cummins Engines

Beyond the K19 series, the Water Inlet Connection part 3074681 is also utilized in various other Cummins engine models. Its design and functionality remain consistent across different engine types, ensuring that coolant is effectively managed and circulated. This part is engineered to withstand the high pressures and temperatures typical of engine environments, contributing to the longevity and performance of the engine.

The Water Inlet Connection part 3074681 is a testament to Cummins’ commitment to quality and reliability. Its use across multiple engine models underscores its versatility and importance in maintaining the integrity of the engine’s cooling system.

Role of Part 3074681 Water Inlet Connection in Engine Systems

The water inlet connection, identified by part number 3074681, is integral to the efficient operation of various engine systems, particularly those involving air compressors and water-cooled compressors.

In an air compressor system, the water inlet connection facilitates the introduction of water into the system, which is essential for cooling the compressor during operation. This cooling is vital to maintain optimal performance and prevent overheating, which can lead to component failure.

When integrated with a B-W compressor water supply tube, the water inlet connection ensures a steady and regulated flow of water to the compressor. This setup is particularly important in high-demand applications where consistent cooling is required to sustain compressor efficiency and longevity.

For compressor units that rely on water for cooling, the water inlet connection acts as the primary interface for water entry. It connects to the water inlet tube, which transports water from the supply source to the compressor. This connection is designed to withstand the pressures and temperatures associated with compressor operation, ensuring reliable performance.

In systems where an air and water mixture is used, such as in certain industrial applications, the water inlet connection plays a role in maintaining the correct balance of these elements. This balance is essential for the effective operation of the compressor and the overall system.

Overall, the water inlet connection (part 3074681) is a key component in ensuring that water-cooled compressors and related systems operate efficiently and reliably. Its proper installation and maintenance are essential for the sustained performance of these engine systems.

Conclusion

The 3074681 Water Inlet Connection is a vital component in the cooling systems of commercial trucks and various Cummins engines. Its role in facilitating efficient coolant flow contributes to engine performance, longevity, and overall reliability. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Steve Rendle and Martynn Randall, Haynes Diesel Engine Systems and Data Book (Haynes Publishing, 2000).

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality (SAE International, 2012).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.