This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3068676 Water Transfer Tube is a component designed for use in commercial trucks, specifically within the engine cooling system. Its purpose is to facilitate the efficient transfer of coolant between the engine and the radiator. Efficient water transfer is vital for maintaining optimal engine temperature, which in turn ensures the engine operates within its designed parameters, contributing to both performance and longevity 1.

Basic Concepts of Water Transfer Tubes

Water transfer tubes operate on the principle of facilitating the movement of coolant within the engine cooling system. These tubes connect critical components, allowing coolant to circulate and absorb heat from the engine. Maintaining optimal coolant flow is significant for engine performance and longevity, as it ensures that heat is effectively dissipated, preventing overheating and potential engine damage 3.

Purpose and Function of the 3068676 Water Transfer Tube

The 3068676 Water Transfer Tube plays a specific role in the engine cooling system by aiding in the circulation of coolant between the engine and radiator. This circulation is crucial for regulating engine temperature. Efficient coolant transfer helps in dissipating heat generated by the engine, ensuring that the engine remains within its optimal operating temperature range 2.

Key Features

The design and construction of the 3068676 Water Transfer Tube include features that enhance its performance and durability. Constructed from high-quality materials, this tube is built to withstand the pressures and temperatures within the engine cooling system. Its unique attributes, such as precise engineering and robust construction, contribute to reliable coolant transfer, ensuring consistent engine cooling efficiency 4.

Benefits of Using the 3068676 Water Transfer Tube

Utilizing the 3068676 Water Transfer Tube offers several advantages. It contributes to improved engine cooling efficiency, which can reduce the risk of overheating. Enhanced coolant circulation leads to better overall engine performance and can result in more reliable truck operation. Additionally, efficient cooling can lead to maintenance savings by reducing the likelihood of engine damage due to overheating 1.

Installation and Compatibility

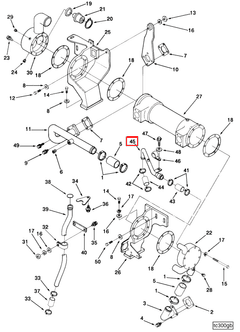

Proper installation of the 3068676 Water Transfer Tube is crucial for its effective function. It is compatible with various Cummins engine models and other relevant truck makes and models. Following manufacturer guidelines ensures a secure and effective installation, which is vital for the tube’s performance and the overall efficiency of the engine cooling system 2.

Troubleshooting Common Issues

Common problems associated with water transfer tubes can include coolant leaks or inadequate cooling. Symptoms of a malfunctioning tube may manifest as overheating or visible coolant leaks. Troubleshooting methods involve inspecting the tube for signs of wear or damage, checking connections for leaks, and ensuring that the tube is properly installed and free from obstructions 3.

Maintenance Tips

Regular maintenance of the 3068676 Water Transfer Tube is important for ensuring continued efficient operation. Inspection procedures should be conducted periodically to check for any signs of wear or damage. Cleaning guidelines may include flushing the cooling system to remove any contaminants that could impede coolant flow. Replacement intervals should be observed to prevent failure due to aging or excessive wear 4.

Cummins Corporation

Cummins Inc. is a leader in the design and manufacture of diesel engines, including a wide range of components for engine systems. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s engine components, including the 3068676 Water Transfer Tube, are designed to meet high standards of performance and reliability.

Water Transfer Tube (Part 3068676) Compatibility with Cummins Engines

The Water Transfer Tube, identified by the part number 3068676, is a critical component in the cooling system of several Cummins engines. This part is engineered to facilitate the transfer of coolant between different parts of the engine, ensuring optimal thermal management and efficiency.

V903 and VTA903 Engines

The V903 and VTA903 engines are part of Cummins’ lineup of heavy-duty diesel engines. The Water Transfer Tube is specifically designed to fit these engines, ensuring seamless integration with the cooling system. This part is crucial for maintaining the engine’s operational temperature, preventing overheating, and ensuring longevity.

CM2250 and V105 Engines

Similarly, the CM2250 and V105 engines also benefit from the use of the Water Transfer Tube. These engines, known for their robust performance and reliability, require precise thermal management to operate efficiently. The part 3068676 is engineered to meet the specific needs of these engines, providing a reliable and durable solution for coolant transfer.

Key Considerations

- Precision Fitment: The Water Transfer Tube is designed to fit perfectly with the cooling systems of the V903, VTA903, CM2250, and V105 engines, ensuring no gaps or leaks.

- Durability: Made from high-quality materials, this part is built to withstand the harsh conditions within the engine compartment.

- Ease of Installation: The design of the Water Transfer Tube allows for straightforward installation, minimizing downtime and ensuring quick return to operation.

By ensuring that the Water Transfer Tube is compatible with these engines, Cummins maintains its commitment to providing reliable and efficient engine components.

Role of Part 3068676 Water Transfer Tube in Engine Systems

The Part 3068676 Water Transfer Tube is integral to the efficient operation of several engine components, ensuring optimal performance and longevity.

Integration with Aftercooler Tube

In systems equipped with an aftercooler, the Water Transfer Tube facilitates the movement of coolant between the engine and the aftercooler. This process helps in reducing the temperature of the compressed air from the turbocharger before it enters the engine’s combustion chamber. By maintaining lower air temperatures, the Water Transfer Tube aids in enhancing engine efficiency and power output.

Collaboration with Cooler

The Water Transfer Tube also plays a significant role when integrated with a cooler, such as an oil cooler or transmission cooler. It ensures a consistent flow of coolant, which is essential for dissipating heat generated by the engine or transmission. This heat management is vital for preventing overheating and ensuring the lubricants within the system remain at optimal viscosity for effective performance.

Function in Torque Converter Oil Systems

In applications involving a torque converter, the Water Transfer Tube is responsible for transferring coolant to and from the torque converter. This helps in managing the heat generated during the transmission of power from the engine to the transmission. Effective cooling of the torque converter oil is essential for maintaining the efficiency of power transfer and preventing damage to the transmission components.

Overall, the Part 3068676 Water Transfer Tube is a key component in maintaining the thermal balance within various engine systems, contributing to their reliable and efficient operation.

Conclusion

The Cummins 3068676 Water Transfer Tube is a vital component in the engine cooling systems of commercial trucks. Its role in facilitating efficient coolant transfer ensures optimal engine temperature, contributing to engine performance and longevity. Proper installation, regular maintenance, and troubleshooting of common issues are essential for maximizing the benefits of this Cummins part. Compatibility with various Cummins engines underscores its importance in the thermal management of these robust and reliable engines.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ ↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ ↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩ ↩ -

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines (The MIT Press, 2010).

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.