This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

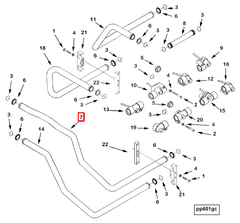

The Water Transfer Tube, identified by Part #3066355, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This tube is integral to the efficient operation of commercial trucks, particularly in maintaining the cooling system’s functionality. Cummins, known for its robust and reliable engine components, ensures that this part meets the demanding requirements of heavy-duty applications 1.

Function and Operation

The Water Transfer Tube operates within the truck’s cooling system by facilitating the movement of coolant between various components. Its primary role is to ensure a consistent flow of coolant, which is vital for dissipating heat generated by the engine. By connecting different parts of the cooling system, it helps maintain optimal engine temperature, thereby supporting efficient engine operation 2.

Key Features

The Water Transfer Tube is designed with specific features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The tube’s dimensions are precisely engineered to fit within the cooling system without impeding coolant flow. Additionally, its design may include features such as reinforced connections to withstand the pressures within the system 3.

Benefits

Incorporating the Water Transfer Tube into a truck’s cooling system offers several advantages. It contributes to improved coolant flow, which is crucial for effective heat dissipation. This enhancement in coolant circulation can lead to more efficient engine cooling, potentially improving overall engine performance and extending its operational life. The consistent coolant flow also helps in maintaining stable engine temperatures under various operating conditions.

Installation and Compatibility

Proper installation of the Water Transfer Tube is key to ensuring its effective operation. It is important to follow manufacturer guidelines for installation, which may include specific torque settings for fasteners and ensuring all connections are secure. Compatibility with various truck models and engine types should be verified to ensure optimal performance and integration within the existing cooling system.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube is recommended to ensure its continued efficient operation. This may include regular inspections for signs of wear or damage, and ensuring all connections remain tight and secure. Common issues that may arise include leaks or blockages, which can be addressed by inspecting the tube and connections, and making necessary repairs or replacements.

Safety Considerations

When working with the Water Transfer Tube, it is important to adhere to safety precautions to minimize the risk of injury or equipment damage. This includes ensuring the engine is cool before beginning any work, using appropriate tools and personal protective equipment, and following all manufacturer guidelines for handling, installation, and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product line and global presence underscore its leadership in the power industry.

Water Transfer Tube (Part 3066355) in Cummins Engines

The Water Transfer Tube, identified by the part number 3066355 and manufactured by Cummins, is a critical component in the cooling system of certain Cummins engines. This part facilitates the transfer of coolant between different sections of the engine, ensuring efficient thermal management and preventing overheating.

Application in Cummins K38 Engines

In the Cummins K38 engine series, the Water Transfer Tube is integral to maintaining optimal operating temperatures. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The Water Transfer Tube in the K38 engine ensures that coolant flows seamlessly from the water pump to various parts of the engine block, enhancing heat dissipation and overall engine longevity.

Grouping of Engines

While the Water Transfer Tube is specifically designed for the Cummins K38 engine, it is essential to understand that similar components may be used across different engine models within the Cummins portfolio. Cummins engines are known for their modular design, which allows for parts compatibility across various engine types. Therefore, the Water Transfer Tube in the K38 engine shares design principles with other Cummins engines, ensuring a standardized approach to thermal management.

Importance of the Water Transfer Tube

The Water Transfer Tube’s role in the engine’s cooling system cannot be overstated. By ensuring a consistent flow of coolant, it helps maintain the engine’s temperature within safe limits, preventing damage from overheating. This part is crucial for the longevity and efficiency of the engine, making it a key component in the maintenance and repair of Cummins engines.

Role of Part 3066355 Water Transfer Tube in Engine Systems

The Water Transfer Tube, identified by part number 3066355, is an integral component in the efficient operation of various engine systems, particularly those involving aftercoolers and performance enhancements.

In systems equipped with an Aftercooler Core, the Water Transfer Tube facilitates the movement of coolant between the core and other components. This ensures that the air entering the engine is adequately cooled, which is essential for optimal engine performance and longevity.

When integrated with the Aftercooler Left Bank Return Plumbing, the tube plays a role in returning cooled water from the left bank of the aftercooler back into the system. This return flow is vital for maintaining a consistent coolant temperature and pressure, which directly impacts the engine’s efficiency and power output.

In broader Aftercooler Plumbing setups, the Water Transfer Tube is a key conduit that ensures the smooth circulation of coolant throughout the aftercooling system. This circulation is necessary for dissipating heat effectively, which is a significant factor in enhancing engine performance.

For Performance Parts and Performance Systems, the inclusion of the Water Transfer Tube is often a strategic choice. It allows for improved coolant management, which is a fundamental aspect of upgrading engine performance. By ensuring that the coolant is efficiently transferred and utilized, the tube contributes to the overall effectiveness of performance-oriented modifications.

Conclusion

In summary, the Water Transfer Tube (part 3066355) is a component that, while seemingly simple, plays a significant role in the complex interplay of parts within engine systems. Its proper function is essential for the effective operation of aftercoolers and the enhancement of engine performance.

-

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.