This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3056795 Water Transfer Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the engine cooling system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for maintaining optimal engine performance.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a part of the engine cooling system that facilitates the movement of coolant between different sections of the engine. Its function is to ensure that coolant is evenly distributed, which helps in maintaining the engine at an optimal operating temperature. This is achieved through a series of passages and channels within the tube that allow coolant to flow efficiently 1.

Purpose of the Cummins 3056795 Water Transfer Tube

This Cummins part plays a role in the operation of a truck by ensuring that coolant is effectively circulated within the engine. This circulation is vital for dissipating heat generated during engine operation, thereby preventing overheating and potential damage. Its function within the cooling system directly impacts engine performance by maintaining a stable operating temperature 2.

Key Features

The 3056795 is characterized by several key features that enhance its performance. These include a durable material composition designed to withstand the high temperatures and pressures within the engine cooling system. Its design incorporates precise channels and passages that optimize coolant flow. Additionally, it may feature unique characteristics such as corrosion-resistant coatings or reinforced sections to improve longevity and reliability 3.

Benefits

Using this part offers several benefits. It contributes to improved engine cooling efficiency by ensuring that coolant is effectively distributed throughout the engine. This results in better temperature regulation, which can enhance engine performance and longevity. The tube’s durable construction and design features also contribute to its reliability, reducing the likelihood of failures or leaks within the cooling system.

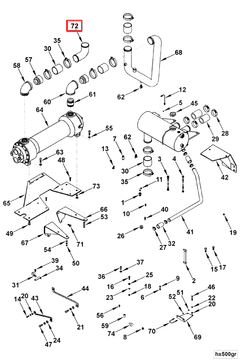

Installation Process

Installing the 3056795 involves several steps to ensure proper integration into the engine cooling system. The process typically requires specific tools and may involve disconnecting and reconnecting coolant lines. It is important to follow manufacturer guidelines to ensure that the tube is correctly positioned and secured, and that all connections are properly sealed to prevent leaks.

Troubleshooting Common Issues

Common issues with this Cummins part may include leaks or blockages within the coolant passages. Troubleshooting these issues involves inspecting the tube for signs of damage or wear, checking connections for proper sealing, and ensuring that coolant flow is not obstructed. Addressing these issues promptly can help maintain the efficiency of the engine cooling system.

Maintenance Tips

Regular maintenance of the 3056795 is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, checking connections for leaks, and ensuring that the coolant system is free of contaminants. Following manufacturer recommendations for maintenance intervals and procedures can help prevent issues and extend the life of the tube.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive industry for producing reliable and high-performance components.

Cummins Water Transfer Tube 3056795 Compatibility

The Cummins Water Transfer Tube part number 3056795 is designed to fit seamlessly within various engine configurations, ensuring efficient coolant flow and optimal engine performance. This part is engineered to meet the stringent requirements of Cummins engines, providing reliable and durable performance in demanding applications.

V28 Engines

The V28 engine series, known for its robust design and high power output, integrates the Water Transfer Tube 3056795 as a critical component. This part ensures that coolant is effectively transferred between different sections of the engine, maintaining consistent temperatures and preventing overheating. The precision engineering of the tube guarantees that it fits perfectly within the V28 engine’s architecture, contributing to the engine’s overall efficiency and longevity.

In the V28 engine, the Water Transfer Tube 3056795 is strategically placed to facilitate optimal coolant circulation. Its design allows for smooth integration with the engine’s cooling system, ensuring that all critical components receive adequate cooling. This is particularly important in high-performance and heavy-duty applications where thermal management is crucial.

The compatibility of the Water Transfer Tube 3056795 with the V28 engine underscores Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance and durability.

Role of Part 3056795 Water Transfer Tube in Engine Systems

The part 3056795 Water Transfer Tube is an essential component in the efficient operation of engine systems, particularly in the context of heat management. This component facilitates the movement of coolant between various parts of the engine, ensuring optimal thermal conditions are maintained.

Integration with Heat Exchanger

The Water Transfer Tube is integral to the functionality of the heat exchanger. It allows for the circulation of coolant, which absorbs heat from the engine and transfers it to the heat exchanger. Here, the heat is dissipated into the surrounding environment, typically through air or another cooling medium. This process is vital for maintaining the engine’s operating temperature within safe limits 4.

Contribution to Cooling System Efficiency

In conjunction with the heat exchanger, the Water Transfer Tube enhances the overall efficiency of the engine’s cooling system. By ensuring a consistent flow of coolant, it helps in evenly distributing the thermal load across the engine components. This balanced heat distribution prevents hotspots, which can lead to engine wear or damage.

Supporting Engine Performance

The effective operation of the Water Transfer Tube directly influences engine performance. By maintaining a stable engine temperature, it ensures that the engine operates within its designed parameters. This stability is essential for the longevity of engine components and the overall reliability of the engine system.

Role in Thermal Management

In thermal management systems, the Water Transfer Tube plays a significant role. It is responsible for the timely and efficient transfer of heat from the engine to the heat exchanger. This function is key in preventing overheating, which can adversely affect engine efficiency and lead to potential failures.

Interaction with Other Engine Components

While the primary interaction of the Water Transfer Tube is with the heat exchanger, its role extends to other engine components as well. It ensures that critical parts, such as the cylinder head and engine block, receive adequate cooling. This is particularly important in high-performance engines where thermal management is a key factor in achieving optimal performance.

Conclusion

In summary, the part 3056795 Water Transfer Tube is a fundamental component in the thermal management of engine systems. Its role in facilitating the movement of coolant and interaction with the heat exchanger is essential for maintaining engine efficiency and performance.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.