This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

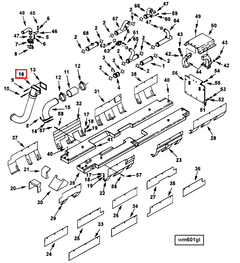

The Water Bypass Connection, part number 3055712, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This Cummins part is integral to the engine cooling system of heavy-duty trucks, ensuring optimal engine performance and efficiency.

Function and Operation

The Water Bypass Connection operates within the engine cooling system by managing the flow of coolant. It allows coolant to bypass the engine block when the thermostat is closed, ensuring that coolant circulates through the system even when the engine is cold. This helps in maintaining a consistent coolant temperature, which is vital for the engine’s operation 1.

Purpose of the Water Bypass Connection

The primary role of the Water Bypass Connection in a truck’s engine system is to regulate coolant flow, which directly impacts engine performance and efficiency. By ensuring that coolant circulates effectively, it helps in maintaining the engine’s operating temperature, which is crucial for its longevity and performance 2.

Key Features

The Water Bypass Connection 3055712 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the harsh conditions of heavy-duty truck engines. Its design ensures a secure fit within the engine system, and it includes specific attributes that improve its efficiency in managing coolant flow 3.

Benefits

The advantages of using the Water Bypass Connection include improved engine cooling, which leads to better overall engine performance. Its durable construction ensures longevity, reducing the need for frequent replacements. Additionally, efficient coolant management can contribute to potential fuel efficiency gains, making it a valuable component in heavy-duty truck engines 4.

Installation Process

Installing the Water Bypass Connection requires careful attention to ensure it fits securely within the engine system. The process involves disconnecting the old connection, cleaning the area, and then fitting the new part. It is important to follow the manufacturer’s guidelines to avoid common pitfalls such as improper fitting or leaks.

Common Issues and Troubleshooting

Typical problems associated with the Water Bypass Connection may include leaks or inefficient coolant flow. Troubleshooting these issues often involves checking the connection for proper fit and ensuring there are no obstructions in the coolant path. Regular inspections can help in identifying and resolving these issues promptly.

Maintenance Tips

To ensure the longevity and optimal performance of the Water Bypass Connection, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring there are no leaks, and checking that the connection remains secure. Following these practices can help in maintaining the efficiency of the engine cooling system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. With a history of innovation and quality, Cummins provides solutions that enhance the performance and efficiency of heavy-duty trucks. The company’s commitment to excellence is reflected in its products, including the Water Bypass Connection 3055712.

Role of Part 3055712 Water Bypass Connection in Engine Systems

The Water Bypass Connection 3055712 is an essential component in the efficient operation of various engine systems. It facilitates the controlled flow of coolant, ensuring optimal engine temperature management and performance.

Integration with Housing and Thermostat

In conjunction with the engine housing and thermostat, the Water Bypass Connection plays a significant role in regulating coolant flow. When the engine is cold, the thermostat remains closed, directing coolant through the bypass connection. This ensures that the coolant circulates through the engine block and cylinder head, gradually warming up the engine. As the engine reaches operating temperature, the thermostat opens, allowing coolant to flow through the radiator for cooling. The bypass connection ensures a consistent coolant flow, preventing overheating and maintaining engine efficiency.

Interaction with Manifold

The Water Bypass Connection also interacts with the engine manifold. It provides an alternative path for coolant when the primary coolant passages are restricted or blocked. This helps in maintaining a uniform coolant distribution across the engine components, enhancing overall engine performance and longevity.

Coordination with Water, Water Bypass Tube, and Water Transfer Tube

The Water Bypass Connection works in harmony with the water system, water bypass tube, and water transfer tube. It ensures that coolant is efficiently routed through these components, facilitating heat exchange and temperature regulation. The bypass connection allows coolant to flow directly to the water transfer tube when necessary, bypassing the thermostat and ensuring continuous coolant circulation. This is particularly important during engine warm-up and in situations where the thermostat may not be fully operational.

Conclusion

In summary, the Water Bypass Connection 3055712 is a vital component that ensures the smooth and efficient operation of the engine’s cooling system. Its role in managing coolant flow, in coordination with other components, is essential for maintaining optimal engine temperature and performance.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.