This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3047105 Water Transfer Tube is a vital component in commercial trucks, designed to circulate coolant within the engine cooling system. This ensures the engine operates at optimal temperatures, maintaining efficiency and longevity by preventing overheating 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube serves as a conduit in the engine cooling system, allowing coolant to flow between different engine parts. This circulation maintains a consistent temperature, absorbing heat from the engine and dissipating it through the radiator. This process is essential for engine performance and longevity, preventing overheating and potential damage 2.

Purpose of the 3047105 Water Transfer Tube

The Cummins 3047105 Water Transfer Tube circulates coolant throughout the engine, maintaining temperature within a specified range for optimal performance. By preventing overheating, it contributes to the truck’s overall efficiency and reliability 3.

Key Features

This Cummins part is characterized by its robust design and high-quality, corrosion-resistant materials, ensuring durability and long-term performance. Its design allows for efficient coolant flow, enhancing the cooling system’s effectiveness 4.

Benefits

Using the 3047105 Water Transfer Tube improves engine cooling efficiency through consistent coolant circulation. Its durable construction enhances reliability, reducing the likelihood of failures. Additionally, its design improves the overall performance of the engine cooling system.

Installation Process

Installing this part involves ensuring the engine is cool and the cooling system is drained. Locate the tube’s position, remove any old or damaged tubes, and install the new tube, ensuring all connections are secure. Refill the cooling system with the appropriate coolant and check for leaks. Required tools may include wrenches and a coolant funnel.

Common Issues and Troubleshooting

Common issues with this part may include leaks, blockages, or corrosion. To troubleshoot, inspect the tube for visible damage or leaks. If a blockage is suspected, flush the cooling system to remove any debris. Corrosion can be addressed by replacing the tube and ensuring the cooling system is properly maintained with the correct coolant.

Maintenance Tips

Regular maintenance is recommended to ensure the optimal performance and longevity of the 3047105 Water Transfer Tube. This includes inspecting the tube for signs of wear or damage during routine engine checks, cleaning the tube, and ensuring there are no obstructions in the coolant flow. Additionally, using the recommended coolant and following the manufacturer’s maintenance schedule will contribute to the tube’s durability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its innovative solutions and commitment to quality. The company offers a wide range of products for various industries, including automotive, construction, and power generation, and is recognized for its reliability and performance in the market.

Compatibility

The Cummins Water Transfer Tube part number 3047105 is compatible with several engine models, facilitating the transfer of coolant between the engine block and the radiator. This ensures optimal thermal management and engine performance.

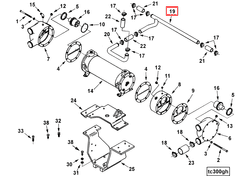

V903 Engine Group

The V903 engine series integrates the Water Transfer Tube 3047105 seamlessly. This part is essential for maintaining coolant flow, dissipating heat effectively, and preventing engine overheating.

Role in Engine Systems

The 3047105 Water Transfer Tube is integral to the efficient operation of several engine systems. Its primary function is to facilitate the smooth transfer of water between various components, ensuring optimal performance and longevity of the engine.

Interaction with the Cooler

In engine systems equipped with a cooler, the 3047105 Water Transfer Tube ensures that the coolant is effectively circulated through the cooler, maintaining the engine’s temperature within safe operating limits. This is particularly important in high-performance engines where overheating can lead to severe damage.

Contribution to Torque Converter Oil Cooling

The torque converter relies on a consistent supply of cool oil to function efficiently. The 3047105 Water Transfer Tube aids in this process by transferring water to the oil cooler, where it absorbs heat from the oil. This heat exchange is vital for maintaining the viscosity and performance of the torque converter oil, thereby ensuring smooth power transmission and reducing the risk of overheating.

Coordination with Water Bypass Tubes

In systems that incorporate water bypass tubes, the 3047105 Water Transfer Tube works in tandem to manage the flow of water. This coordination is essential during varying engine loads and temperatures. By efficiently directing water flow, the tube helps in maintaining a balanced thermal environment within the engine, enhancing overall performance and reliability.

Conclusion

The 3047105 Water Transfer Tube plays a crucial role in maintaining the efficiency and reliability of engine systems by ensuring optimal coolant circulation. Its robust design, durable construction, and precise engineering make it a critical component in the cooling systems of various engine models, contributing to the overall performance and longevity of the engine.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.