3040055

Water Transfer Tube

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3040055 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the vehicle 2.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to flow between the engine and the radiator. This tube operates by channeling coolant from the engine, where it absorbs heat, to the radiator, where the heat is dissipated into the air. This continuous circulation helps to regulate engine temperature and prevent overheating 1.

Purpose of the 3040055 Water Transfer Tube

This part plays a role in the truck’s cooling system by enabling the movement of coolant between the engine and radiator. This facilitates efficient heat exchange, ensuring that the engine operates within its optimal temperature range. By maintaining a consistent coolant flow, the tube contributes to the overall stability and performance of the engine 2.

Key Features

The 3040055 is constructed from durable materials that resist corrosion and wear, ensuring longevity in harsh operating conditions. Its design includes precise fittings and connections that allow for a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand high pressure and temperature fluctuations, enhancing its performance and durability 2.

Benefits

The advantages provided by this Cummins part include improved coolant flow, which leads to more effective heat management. This results in enhanced engine protection against overheating and potential damage. Furthermore, the tube’s robust construction and design contribute to increased reliability, even under demanding conditions typical of heavy-duty truck operations 2.

Installation Process

To install the Water Transfer Tube, begin by ensuring the engine is cool and the cooling system is drained. Gather the necessary tools, such as wrenches and sealant. Follow the manufacturer’s instructions for removing the old tube and installing the new one, ensuring all connections are tight and secure. It is advisable to use the recommended sealant to prevent leaks and verify that the tube is properly aligned within the cooling system 2.

Common Issues and Troubleshooting

Typical problems associated with Water Transfer Tubes include leaks or blockages. To diagnose these issues, inspect the tube and connections for signs of wear or damage. If a leak is detected, the tube may need to be replaced or repaired. Blockages can often be resolved by flushing the cooling system to remove any debris or contaminants that may be obstructing the flow of coolant 2.

Maintenance Tips

To prolong the lifespan of the 3040055, regular maintenance practices are recommended. This includes periodic inspections for signs of wear or damage, cleaning the tube and connections to prevent buildup, and following the manufacturer’s guidelines for replacement intervals. Keeping the cooling system clean and well-maintained will contribute to the efficient operation of the Water Transfer Tube 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles 3.

Water Transfer Tube (Part 3040055) Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 3040055, is a component in the cooling systems of various Cummins engines. This part is designed to facilitate the transfer of coolant between different sections of the engine, ensuring optimal thermal management and efficiency 3.

N14 Mechanical Engine

In the N14 Mechanical engine, the Water Transfer Tube is integral to the engine’s cooling system. It connects the water pump to the radiator, allowing coolant to flow efficiently and maintain the engine’s operating temperature within the desired range. This tube is crucial for preventing overheating and ensuring the longevity of the engine components 3.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Water Transfer Tube plays a pivotal role in the cooling system. It ensures that coolant is effectively circulated throughout the engine, maintaining consistent temperatures and preventing thermal stress on engine parts. This tube is essential for the efficient operation of the cooling system in these engines 3.

The Water Transfer Tube’s design and material ensure it can withstand the high pressures and temperatures within the engine’s cooling system, providing reliable performance and durability. Its compatibility with both the N14 Mechanical and NH/NT 855 engines underscores its versatility and importance in maintaining engine health 3.

Role of Part 3040055 Water Transfer Tube in Engine Systems

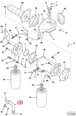

The 3040055 is integral to the efficient operation of several engine components, facilitating the seamless transfer of water between different systems. This component is designed to work in conjunction with the lubrication oil cooler, lube oil cooler, oil filter/cooler, plumbing systems, and the oil cooler water system.

In the context of the lubrication oil cooler and lube oil cooler, the Water Transfer Tube ensures that the cooling water circulates effectively. This circulation is vital for maintaining the optimal temperature of the lubrication oil, which in turn protects the engine’s moving parts from excessive wear and thermal degradation 3.

When integrated with the oil filter/cooler, the Water Transfer Tube plays a role in dissipating the heat generated by the filtration process. This helps in prolonging the life of the oil filter and ensuring that the oil remains clean and effective in lubricating the engine components 3.

The plumbing system benefits from the Water Transfer Tube by providing a dedicated pathway for water transfer, reducing the risk of leaks and ensuring that the water reaches its destination without contamination or loss of pressure 3.

In the oil cooler water system, the Water Transfer Tube is essential for transferring water from the cooling system to the oil cooler. This transfer helps in dissipating the heat absorbed by the oil, thereby maintaining the oil’s viscosity and ensuring it performs its lubricating function efficiently 3.

Overall, the 3040055 is a key component in maintaining the thermal management of the engine, ensuring that all interconnected systems operate within their specified parameters 3.

Conclusion

The Cummins 3040055 Water Transfer Tube is a critical component in the cooling systems of heavy-duty trucks, ensuring optimal engine temperature and performance. Its durable construction, precise design, and compatibility with various Cummins engines make it an essential part for maintaining engine health and efficiency. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.