This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Water Bypass Tube, part number 3039282, is a component designed by Cummins for use in the cooling systems of heavy-duty trucks. Its purpose is to facilitate the efficient circulation of coolant within the engine, ensuring optimal temperature regulation. This part plays a role in maintaining the engine’s performance and longevity by managing the flow of coolant in conjunction with other cooling system components 1.

Function and Operation

The Water Bypass Tube operates by providing an alternative path for coolant to flow when the thermostat is closed. This ensures that coolant continues to circulate through the engine block and head, even when the radiator is not yet engaged in the cooling process. The tube interacts with the thermostat and radiator to maintain a consistent coolant flow, which helps in stabilizing engine temperature and preventing overheating 2.

Key Features

The Water Bypass Tube is constructed from durable materials that resist corrosion and wear, ensuring long-term reliability. Its design includes precise fittings and connections that integrate seamlessly with the engine’s cooling system components. The tube’s robust construction and material choice contribute to its ability to withstand high temperatures and pressures typical in heavy-duty truck engines 3.

Benefits

The incorporation of the Water Bypass Tube into the engine cooling system offers several advantages. It enhances engine temperature regulation by ensuring continuous coolant circulation, which contributes to more stable engine operation. Additionally, the tube supports improved engine efficiency and can lead to prolonged engine life by reducing the risk of overheating and associated damage.

Installation and Integration

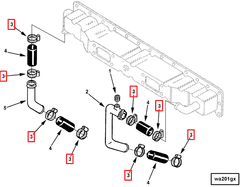

Proper installation of the Water Bypass Tube involves ensuring that all connections are secure and that the tube is correctly positioned within the engine cooling system. It is important to follow manufacturer guidelines to confirm that the tube functions as intended. This may include verifying that the thermostat and radiator are correctly installed and operational.

Maintenance and Troubleshooting

Routine maintenance of the Water Bypass Tube includes regular inspections for signs of wear, corrosion, or leaks. It is advisable to check the tube during scheduled engine maintenance intervals. Troubleshooting common issues may involve inspecting connections for tightness, looking for coolant leaks, and ensuring that the tube is free from obstructions.

Common Failure Modes

Typical failure modes for the Water Bypass Tube can include corrosion, cracking, or blockages. These issues may arise from prolonged exposure to high temperatures, coolant contaminants, or physical damage. Addressing these failures often involves cleaning the cooling system, replacing damaged components, and ensuring that the coolant is free from impurities.

Diagnostic Techniques

Assessing the condition and performance of the Water Bypass Tube can be achieved through visual inspections and performance tests. Visual checks should look for physical damage or leaks, while performance tests may involve monitoring engine temperature under various operating conditions to ensure that the cooling system is functioning correctly.

Replacement Procedures

Replacing a faulty Water Bypass Tube requires careful removal of the old tube, ensuring that all connections are disconnected properly. The new tube should be installed according to manufacturer specifications, with attention to securing all connections and ensuring proper alignment within the cooling system. Special tools may be required for certain steps in the replacement process.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation and quality in the automotive and heavy-duty truck industries. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial and industrial applications.

Water Bypass Tube (Part 3039282) Compatibility with Cummins Engines

The Water Bypass Tube, identified by part number 3039282 and manufactured by Cummins, is a component in the cooling system of various Cummins engines. This part is designed to manage the flow of coolant, ensuring efficient engine operation and preventing overheating.

L10 Mechanical Engines

The Water Bypass Tube (3039282) is specifically engineered to fit within the cooling system architecture of the L10 Mechanical engines. These engines are known for their robust design and are often utilized in heavy-duty applications where reliability and performance are paramount. The tube’s role in these engines is to redirect coolant flow, optimizing thermal management and enhancing overall engine efficiency.

Group Compatibility

The Water Bypass Tube (3039282) is compatible with a range of Cummins engine groups, ensuring it can be integrated into various cooling system configurations. This adaptability makes it a versatile component for technicians and engineers working with Cummins engines. The part’s design allows it to fit seamlessly into the cooling pathways of these engines, providing a reliable solution for maintaining optimal coolant flow.

Specific Engine Models

While the Water Bypass Tube (3039282) is broadly compatible with several Cummins engines, it is particularly noted for its fit in the following models:

- L10 Mechanical Engines: As previously mentioned, this part is specifically designed to integrate with the L10 Mechanical engines, ensuring precise coolant management.

- Other Cummins Engines: The tube’s design and specifications also make it suitable for other Cummins engine models, providing a consistent and reliable performance across different engine types.

By understanding the compatibility of the Water Bypass Tube (3039282) with various Cummins engines, technicians and engineers can ensure that their cooling systems are optimized for performance and longevity. This part’s integration into the engine’s cooling system is crucial for maintaining engine health and preventing thermal-related issues.

Role of Part 3039282 Water Bypass Tube in Engine Systems

The Water Bypass Tube, identified by part number 3039282, is a component in the efficient operation of various engine systems, particularly those involving aftercooler plumbing and water management.

In systems with aftercooler plumbing, the Water Bypass Tube facilitates the regulated flow of water, ensuring that the aftercooler operates within optimal temperature ranges. This is achieved by allowing excess water to bypass the aftercooler when temperatures are satisfactory, preventing unnecessary cooling and maintaining engine efficiency.

When integrated into general plumbing systems within the engine, the Water Bypass Tube helps in managing water flow to different components, ensuring that each part receives the appropriate amount of water for cooling and lubrication. This balanced distribution is key to preventing overheating and extending the lifespan of engine components.

In setups involving an aftercooler with water (Aftercooler WTR), the Water Bypass Tube plays a significant role in temperature control. By bypassing water around the aftercooler when it is not needed for cooling, the tube helps in maintaining a consistent temperature, which is vital for the performance and reliability of the aftercooler and the overall engine system.

Overall, the Water Bypass Tube is a key component in the thermal management of engine systems, contributing to the stability and efficiency of engine operations.

Conclusion

The Water Bypass Tube, part number 3039282, is a critical component in the cooling systems of Cummins engines, designed to ensure efficient coolant circulation and temperature regulation. Its durable construction, precise design, and compatibility with various Cummins engine models make it a reliable choice for maintaining engine performance and longevity. Proper installation, maintenance, and understanding of its role in engine systems are essential for optimizing its benefits.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.