This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

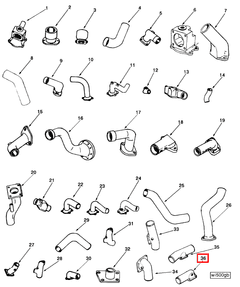

Introduction

The Water Bypass Connection 3039245 is a component designed to facilitate the efficient operation of engine cooling systems in commercial trucks. Manufactured by Cummins, a well-established name in the industry known for its commitment to quality and innovation in engine technology, this part plays a role in the engine cooling system by managing coolant flow, which is vital for maintaining optimal engine temperature and performance 1.

Basic Concepts of Water Bypass Connection

Water bypass connections are integral to engine cooling systems. They allow coolant to circulate through the engine block and radiator, ensuring that the engine operates within a safe temperature range. By providing an alternative path for coolant flow, these connections help regulate temperature and prevent overheating. This is particularly important in heavy-duty applications where engines are subjected to high loads and varying operating conditions 2.

Purpose of the 3039245 Water Bypass Connection

The 3039245 Water Bypass Connection is specifically designed to aid in the regulation of coolant flow and temperature within the engine cooling system. It ensures that coolant is efficiently distributed, which helps maintain consistent engine temperature. This part contributes to the overall efficiency of the cooling system by allowing coolant to bypass certain areas when necessary, thus optimizing flow and reducing the risk of overheating 3.

Key Features

The 3039245 Water Bypass Connection features a robust design that includes precision-machined components to ensure a secure fit and reliable performance. It is constructed from high-quality materials that are resistant to corrosion and wear, enhancing its durability. Unique attributes of this part include its ability to handle high-pressure environments and its design, which minimizes the risk of leaks and ensures smooth operation 4.

Benefits

Incorporating the 3039245 Water Bypass Connection into an engine cooling system offers several advantages. It contributes to improved engine efficiency by ensuring that coolant is effectively circulated. This helps reduce wear on engine components, leading to enhanced overall performance and longevity of the engine. Additionally, by maintaining optimal engine temperature, this part plays a role in preventing costly repairs and downtime.

Installation Process

Installing the 3039245 Water Bypass Connection requires careful attention to detail. Begin by ensuring the engine is cool and the cooling system is drained. Use the appropriate tools to remove the old connection, if applicable. Align the new connection with the designated fitting points and secure it in place. It is important to follow manufacturer guidelines for torque specifications to ensure a proper seal. After installation, refill the cooling system and check for leaks to confirm a successful installation.

Troubleshooting Common Issues

Common issues with water bypass connections can include leaks, blockages, and improper alignment. To diagnose these problems, inspect the connection for signs of wear or damage. Check for coolant leaks around the fitting points and ensure there are no obstructions in the coolant passages. If a leak is detected, the connection may need to be reseated or replaced. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3039245 Water Bypass Connection, regular maintenance is recommended. Inspect the connection during routine engine checks for signs of wear or corrosion. Clean the fitting points to remove any debris that could impede proper function. Follow manufacturer guidelines for replacement intervals to prevent failure due to age or excessive use. Proper maintenance will help sustain the efficiency of the engine cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engine and component solutions designed to meet the demanding needs of heavy-duty applications. Cummins’ commitment to excellence is reflected in its continuous investment in research and development, ensuring that its products remain at the forefront of technology and performance.

Water Bypass Connection Part 3039245 in Cummins Engines

The Water Bypass Connection part 3039245 is a critical component in various Cummins engines, ensuring efficient thermal management by regulating the flow of coolant. This part is integral in maintaining optimal engine temperatures and preventing overheating, which is crucial for the longevity and performance of the engine.

V28 Engines

In the V28 engine series, the Water Bypass Connection part 3039245 plays a vital role in the engine’s cooling system. It is designed to connect the water passages, allowing coolant to bypass certain areas of the engine block when necessary. This feature helps in achieving a balanced coolant flow, which is essential for maintaining consistent engine temperatures under varying operational conditions.

The part is engineered to withstand high pressures and temperatures, ensuring durability and reliability. Its precise fit and function are critical for the overall efficiency of the engine’s cooling system, contributing to the engine’s performance and lifespan.

Understanding the Role of Part 3039245 Water Bypass Connection in Engine Systems

The part 3039245 Water Bypass Connection is an essential component in the efficient operation of various engine systems. It facilitates the smooth circulation of coolant within the engine, ensuring optimal temperature regulation and performance.

Integration with Manifold and Water Systems

In engine systems, the manifold plays a significant role in distributing air or fluid to different parts of the engine. The Water Bypass Connection interfaces with the manifold to regulate the flow of coolant. This ensures that the engine components receive a consistent supply of coolant, which is vital for maintaining engine temperature within safe operating limits.

Interaction with Thermostat Housings

Thermostat housings are designed to house the thermostat, which controls the flow of coolant based on engine temperature. The Water Bypass Connection works in conjunction with the thermostat housings to provide an alternative path for coolant flow. This bypass mechanism allows coolant to circulate even when the thermostat is closed, preventing overheating and ensuring continuous cooling.

Role in Water Bypass Assembly Tee

The Water Bypass Assembly Tee is a component that directs the flow of coolant through various pathways. The Water Bypass Connection is integral to this assembly, as it allows coolant to bypass certain sections of the engine when necessary. This feature is particularly important during cold starts, when the engine requires rapid warming to reach optimal operating temperature.

Contribution to Water Manifold Functionality

The Water Manifold is responsible for distributing coolant to different parts of the engine block and cylinder heads. The Water Bypass Connection enhances the functionality of the Water Manifold by providing an additional route for coolant flow. This ensures that all engine components receive adequate cooling, even under varying operating conditions.

By understanding the role of the Water Bypass Connection in these engine components, engineers and mechanics can better appreciate its importance in maintaining engine efficiency and reliability.

Conclusion

The 3039245 Water Bypass Connection by Cummins is a vital component in the efficient operation of engine cooling systems. Its role in managing coolant flow and maintaining optimal engine temperature is crucial for the performance and longevity of commercial truck engines. Proper installation, regular maintenance, and understanding its integration with other engine components are key to ensuring the effectiveness of this part in heavy-duty applications.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.