This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

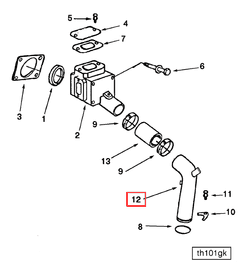

The Cummins 3036998 Water Bypass Tube is a component designed for use in the engine cooling systems of heavy-duty trucks. Its purpose is to facilitate the efficient circulation of coolant within the engine, ensuring that the engine operates within optimal temperature ranges. This part plays a role in the engine cooling system by providing an alternative path for coolant flow, which helps in maintaining consistent engine temperatures under varying operational conditions 1.

Function and Operation

The Water Bypass Tube operates by allowing coolant to bypass the thermostat when the engine is cold, enabling quicker warm-up times and efficient heat distribution. As the engine reaches operating temperature, the thermostat opens, and the bypass tube ensures that coolant flow is regulated to maintain optimal engine temperature. This regulation is vital for preventing overheating and ensuring that the engine operates efficiently 2.

Key Features

This Cummins part is constructed from high-quality materials that offer durability and resistance to corrosion. Its design includes precise engineering to ensure a secure fit within the engine cooling system. The tube is built to withstand the high pressures and temperatures typical of heavy-duty truck engines, contributing to its longevity and reliable performance 3.

Benefits

The use of the Water Bypass Tube offers several advantages. It contributes to improved engine efficiency by ensuring that the engine reaches and maintains its optimal operating temperature more quickly and consistently. This results in reduced risk of overheating, which can lead to engine damage. Additionally, the tube enhances the overall performance of the cooling system, leading to more reliable engine operation under a variety of conditions.

Installation and Compatibility

Proper installation of the Water Bypass Tube is crucial for ensuring its effective operation within the engine cooling system. It is important to follow manufacturer guidelines for installation, including any specific requirements for sealing and securing the tube within the system. Compatibility with various engine models and configurations should be verified to ensure optimal performance and integration within the engine cooling system.

Maintenance and Troubleshooting

Regular maintenance of the Water Bypass Tube is important for ensuring its continued optimal performance. This includes periodic inspection for signs of wear or damage, such as leaks or corrosion. Addressing any issues promptly can prevent more significant problems within the engine cooling system. Troubleshooting techniques may involve checking for proper coolant flow and ensuring that the tube is securely installed and free from obstructions.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality engine components. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and durable parts that contribute to the efficient operation of heavy-duty vehicles. The company’s dedication to quality and performance is evident in its wide range of engine components, including the 3036998 Water Bypass Tube.

Water Bypass Tube 3036998 in Cummins Engines

The Water Bypass Tube 3036998 is a critical component in several Cummins engine models, ensuring efficient thermal management by regulating coolant flow. This part is specifically designed to fit seamlessly within the engine architecture of the NH/NT 855 series.

In the NH/NT 855 engines, the Water Bypass Tube 3036998 is engineered to maintain optimal coolant circulation, preventing overheating and ensuring consistent engine performance. Its placement and design are tailored to integrate smoothly with the engine’s cooling system, facilitating effective heat dissipation.

The integration of the Water Bypass Tube 3036998 in these engines underscores Cummins’ commitment to reliability and durability. This part is crucial for maintaining the engine’s operational efficiency, especially under varying load conditions.

Role of Part 3036998 Water Bypass Tube in Engine Systems

This part is an essential component in the thermal management of engine systems, particularly when integrated with components such as the plumbing aftercooler kit, thermostat housing, and thermostat housing (hsg).

When the engine is cold, the thermostat remains closed, preventing coolant from entering the radiator. During this phase, the water bypass tube allows coolant to circulate between the engine block and the thermostat housing. This ensures that the engine warms up efficiently, reducing wear and improving performance.

In systems equipped with a plumbing aftercooler kit, the water bypass tube plays a significant role in maintaining optimal temperatures. The aftercooler requires a consistent flow of coolant to effectively reduce the temperature of the compressed air before it enters the engine. The bypass tube ensures that coolant is available to the aftercooler even when the thermostat is closed, contributing to the overall efficiency of the cooling system.

Additionally, the water bypass tube aids in stabilizing the temperature within the thermostat housing. By providing an alternative path for coolant flow, it helps to prevent hotspots and ensures uniform temperature distribution throughout the engine. This is particularly important in high-performance engines where thermal management is key to reliability and efficiency.

Conclusion

In summary, the 3036998 Water Bypass Tube is integral to the proper functioning of the cooling system, working in conjunction with the thermostat housing and aftercooler to maintain optimal engine temperatures. Its role in facilitating efficient coolant circulation and thermal management underscores its importance in the operation of heavy-duty truck engines.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Barton, David C, and John D Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.