This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

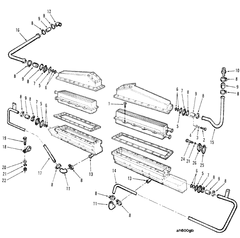

The Water Transfer Tube, identified by Part #3027771, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube is integral to the cooling systems of commercial trucks, facilitating the efficient transfer of coolant. Its role is vital in maintaining the optimal operating temperature of the engine, thereby contributing to the overall performance and longevity of the vehicle 1.

Function and Operation

The Water Transfer Tube operates as a conduit within the truck’s cooling system, responsible for the circulation of coolant between the engine and the radiator. This process is fundamental to dissipating heat generated by the engine, ensuring that the engine operates within safe temperature ranges. The tube’s design allows for a consistent flow of coolant, which absorbs heat from the engine and transfers it to the radiator, where it is then dissipated into the atmosphere 2.

Key Features

The Water Transfer Tube is characterized by its robust design and the use of high-quality materials, which contribute to its durability and efficiency. Constructed from corrosion-resistant materials, the tube is designed to withstand the harsh conditions often encountered in commercial truck operations. Its precise engineering ensures a secure fit within the cooling system, minimizing the risk of leaks and ensuring efficient coolant flow 3.

Benefits

The incorporation of the Water Transfer Tube into a truck’s cooling system offers several advantages. It enhances the cooling performance by ensuring a reliable and consistent flow of coolant, which is crucial for maintaining engine temperature under varying operational conditions. Additionally, its durable construction contributes to the overall reliability of the cooling system, reducing the likelihood of unexpected failures and the associated downtime.

Installation and Compatibility

Proper installation of the Water Transfer Tube is crucial for ensuring its effective operation within the cooling system. It is designed to be compatible with a range of truck models, facilitating its use across different fleets. Detailed guidelines for installation are provided to ensure that the tube is correctly positioned and secured, allowing for optimal performance and longevity.

Maintenance and Troubleshooting

Regular maintenance of the Water Transfer Tube is recommended to ensure its continued efficient operation. This includes periodic inspections for signs of wear or damage, as well as ensuring that all connections are secure. Common issues, such as leaks or reduced coolant flow, can often be traced back to improper installation or wear and tear. Addressing these issues promptly can prevent more significant problems down the line.

Safety Considerations

When working with the Water Transfer Tube, it is important to observe certain safety precautions. This includes ensuring that the engine is cool before attempting any maintenance or repairs to avoid burns from hot coolant. Additionally, proper handling and disposal of coolant are necessary to protect both the environment and the individuals performing the maintenance.

Environmental Impact

The use of the Water Transfer Tube contributes to reduced environmental impact in several ways. By ensuring efficient coolant flow and minimizing leaks, it helps in reducing the amount of coolant that needs to be replaced, thereby decreasing waste. Furthermore, its role in maintaining optimal engine temperature can lead to improved fuel efficiency, reducing the overall carbon footprint of the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. Its extensive product offerings and dedication to quality have established it as a trusted name among commercial vehicle operators and manufacturers alike.

Cummins Water Transfer Tube 3027771 Compatibility

The Cummins Water Transfer Tube part number 3027771 is a critical component in the cooling systems of various engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K50 Engine Series

The K50 engine series, known for its robust performance and reliability, incorporates the Water Transfer Tube 3027771 as part of its cooling system. This part is integral to the engine’s ability to manage thermal loads effectively, ensuring longevity and consistent performance. The K50 engines, often used in heavy-duty applications, benefit from the precise engineering of the Water Transfer Tube, which helps in maintaining the coolant flow and preventing overheating.

Grouping of Engine Models

In the broader context of Cummins engine models, the Water Transfer Tube 3027771 is compatible with several engine variants that share similar cooling system architectures. This part is engineered to fit seamlessly into the cooling pathways of these engines, providing a reliable solution for coolant management. The compatibility of this part across different engine models underscores its versatility and importance in maintaining engine health.

The integration of the Water Transfer Tube 3027771 in these engines highlights Cummins’ commitment to providing high-quality, durable components that enhance engine performance and reliability.

Role of Part 3027771 Water Transfer Tube in Engine Systems

The water transfer tube, identified as part 3027771, is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the movement of water between different parts of the engine, ensuring optimal cooling and performance.

Integration with Performance Parts

In high-performance engines, the water transfer tube plays a significant role in maintaining the engine’s temperature within safe operating limits. By efficiently transferring water from the radiator to the engine block and other critical components, it helps prevent overheating, which can lead to reduced performance and potential engine damage.

Connection to Water Systems

The water transfer tube is integral to the water connection system within the engine. It ensures a consistent flow of coolant, which is vital for dissipating heat generated during combustion. This component connects to the water pump, thermostat, and various coolant passages within the engine block and cylinder head.

The tube’s design allows for a seamless integration with these components, enhancing the overall efficiency of the cooling system. It also aids in reducing thermal stress on engine parts, contributing to longer engine life and reliable performance.

Enhanced Cooling Efficiency

By providing a direct and unobstructed path for coolant flow, the water transfer tube enhances the cooling efficiency of the engine. This is particularly important in performance applications where engines operate at higher temperatures for extended periods.

The consistent flow of coolant ensures that all engine components receive adequate cooling, preventing hot spots and ensuring uniform temperature distribution. This not only improves engine performance but also contributes to the overall reliability of the engine system.

Conclusion

The Water Transfer Tube, part number 3027771, is a critical component in the cooling systems of commercial trucks and various engine models. Its robust design, compatibility with a wide range of engines, and efficient operation contribute to the overall performance, reliability, and longevity of the vehicles it serves. Regular maintenance and proper installation are key to ensuring its optimal function, while its role in efficient coolant management also contributes to reduced environmental impact.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.